Suntes

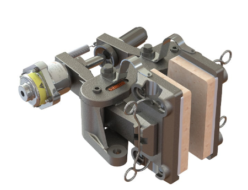

Suntes Structure and operating principle TY type torque reliever

Manufacture: Suntes (Sanyo Shoji Co., Ltd.)

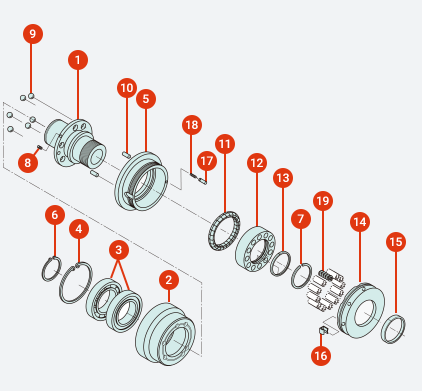

Part Names

- Hub Boss

- Flanges

- bearing

- C-shaped retaining ring for holes

- case

- C-shaped retaining ring for shaft

- WR type retaining ring

- Hexagonal Socket Set Screw

- Steel ball

- Parallel pin

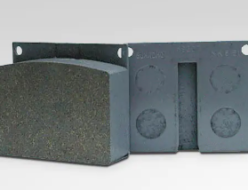

- segment

- Tapered Ring

- Slide Ring

- Adjustable Ring

- metal

- clip

- pin

- Spring

- Spring

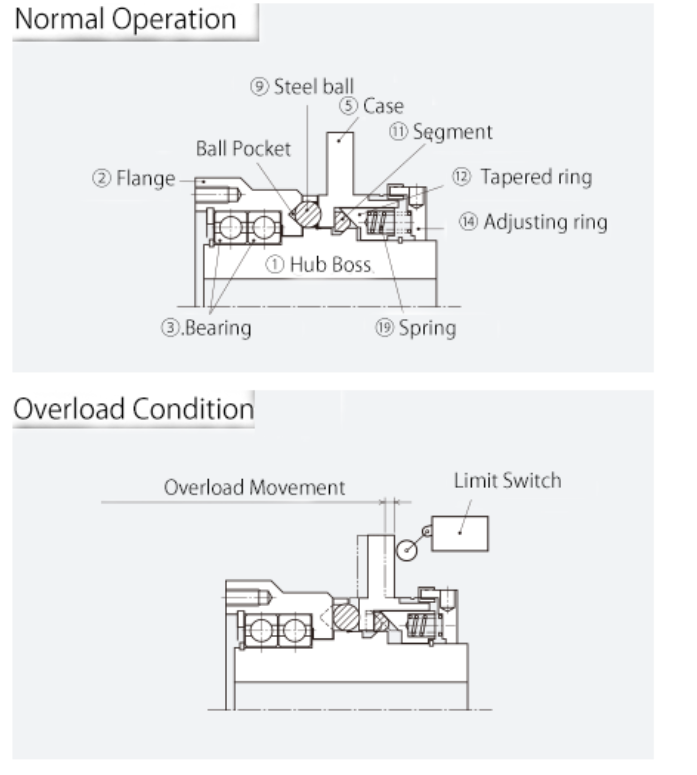

Operation

- During normal operation, the steel ball ⑨ held by the hub boss ① is pressurized and held in the ball pocket of the flange ② by the force of the spring ⑲, and torque is transmitted from the hub boss ① via the steel ball ⑨ to the flange ②.

- In the event of an overload, the steel ball ⑨ is pushed out by the slope of the ball pocket of the flange ②, cutting off the transmitted torque. At the same time, the segment ⑪ moves up the slope of the hub boss protrusion against the force of the spring ⑲, pushing apart the case ⑤ and tapered ring ⑫ and reaching the top of the hub boss protrusion. This removes the force pressing the steel ball ⑨ into the ball pocket of the flange ②, allowing the flange ② to rotate freely on the bearing ③. At this time, the case ⑤ also moves axially (towards the adjusting ring ⑭), and this action can be used to detect an overload with a limit switch, proximity switch, etc.

- To restart the machine, after eliminating the cause of the overload, rotate either the input or output side of the torque releaser until the alignment marks on the hub boss ① and flange ② are aligned, and then press the case ⑤ against the flange ② to reset it.

If you have any questions about specifications, please contact us.

The dimensions and specifications listed may be changed without notice for improvement purposes.