Suntest

Suntest GY Series GYSE-P Probe

Manufacturer: Suntest Co.,Ltd

Model: GYSE-P

Magnetostrictive Displaiacement Transducer

Model GY Series are “Displacement Transducers” employing magnetostrictive phenomena, especially the Wiedemann effect. An ultra-sonic wave is generated by a moving magnet operating near a magnetostrictive wave guide on which the sonic wave propagates up to the head of the transducer.

Model GY Series are “Displacement Transducers” employing magnetostrictive phenomena, especially the Wiedemann effect. An ultra-sonic wave is generated by a moving magnet operating near a magnetostrictive wave guide on which the sonic wave propagates up to the head of the transducer.

The propagation time is precisely measured by state of the art technology and then the absolute displacement transducer is operational.

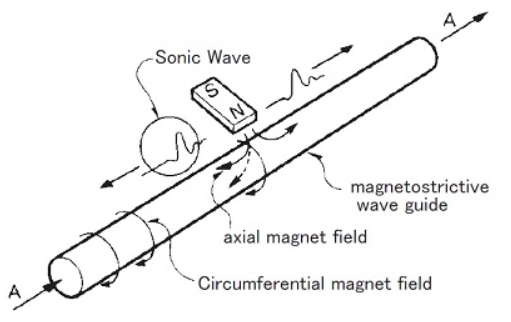

[ Principle ]

The figure shows the fundamental principle of operation.

When a current pulse like A is given to the wave guide, it generates a circumferential magnetic field on the wave guide, then placement of the movable magnet (polarized axially) as shown, only the axial magnetic field of the magnet affecting the wave guide produces a resultant field as indicated by the dotted line.

The vector combination of these two fields produces torsional strain, a phenomenon known as the Wiedemann Effect.

It is a form of vibration and propagates along the wave guide in the form of a transverse ultra-sonic wave.

The GY series displacement transducers detect the propagation time of the ultra-sonic wave.

GYSE-P Probe.

Profibus DP interface (detachable probe element)

GYSE-P is PROFIBUS interface type.

Setting parameters (resolution, output direction) through PROFIBUS is possible.

GSD file is available on SANTEST web site.

Detecting up to 32 pcs of magnets on one probe is possible.

When you use a PROFIBUS master simulator of separate sale, it’s possible to confirm the data and to set up a PROFIBUS slave from a PC without PROFIBUS master (usually, PLC).

- CE marking

- Noise cancellation

Specifications

| Non-linearity | ≦±0.025%FS (Typ.) |

|---|---|

| Resolution | Min. 1μm ( set by Profibus Configurator ) |

| Repeatability | ≦±0.001%FS ( Min. ±3μm ) |

| Temp. drift | ≦±15ppmFS / °C |

| Output | Profibus DPV0 |

| Power supply | +24(±2)VDC (70mA) |

| Sampling freq. | Stroke 〜800mm : 2000Hz 〜2200mm : 1000Hz 〜5000mm : 500Hz 5001mm〜 : 250Hz |

| Max. Pressure | 35MPa ( probe rod ) |

| Operating temp. | -20°C〜+75°C |

| Storage temp. | -40°C〜+75°C |

| Vibration | 15G ( 20〜100Hz ) |

| Shock | 100G ( 2msec ) |

| IP grade | IP67 |

- The above mentioned accuracy applies to sensors with an effective stroke of 300mm or more.

- The specification of stroke less than 300mm is equal that of stroke 300mm.

(*) In case of multi magnets on one probe, sampling frequency is not standard value.

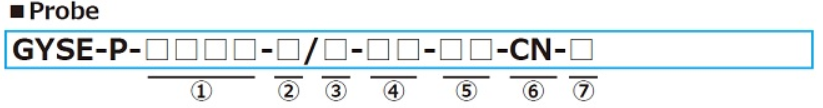

Model No.

① Effective stroke

15〜7500mm

② Head dead zone

50: 50mm(Std.)

□: □mm ( option ) ( specified by customers )

・Possible Min. length depends on the selected magnet or float.

③ Tip dead zone

□: 70mm/ 90mm/ 100mm ( Std.)

| □ | tip DZ | magnet | float |

|---|---|---|---|

| 70 | 70mm | M2PN, M3, M11N, BA | F28N |

| 100 | 100mm | T144, T163 | F40S, F42S, F50S, F54S |

④ Thread / Rod diameter

N :M18xP1.5, rod Φ10 (Std.)

M :M24xP1.0, rod Φ10

M14 :M24xP1.0, rod Φ13.8

⑤ Associated magnet or float

| magnet | float |

|---|---|

| M2PN :No.2PN (Std.) M3 :No.3 M11N :No.11N T144 :No.T14-M4 T163 :No.T16-M3 BA : No.2KYN-17-LG | F40S :Φ40 SS316(B) F42S :Φ43 SS316L F50S :Φ50 SS316L F54S :Φ54 SS304 F28N :RF-A6 plastic |

・Selecting magnet from page 116〜118(GG).

・Please consult our factory in case of requesting special magnet or float.

・This model code means only specifying associated magnet or float.

・Ordering magnet or float individually.

⑥ Cable connection

CN :connector ( Std.)

⑦ Option

blank :without option

SRT :SRT option

L :linearization option (≦0.006% FS Typ.)

2M : temperature compensation (≦±7ppmFS / °C)

2ML : temperature compensation + linearization

・Please confirm the details of SRT option on page 114.

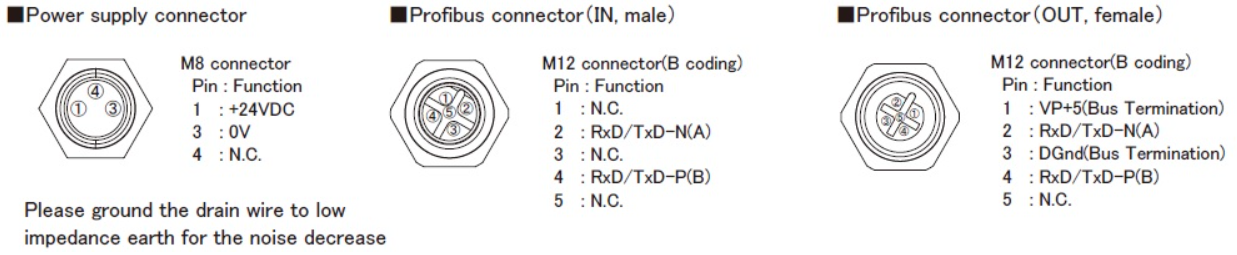

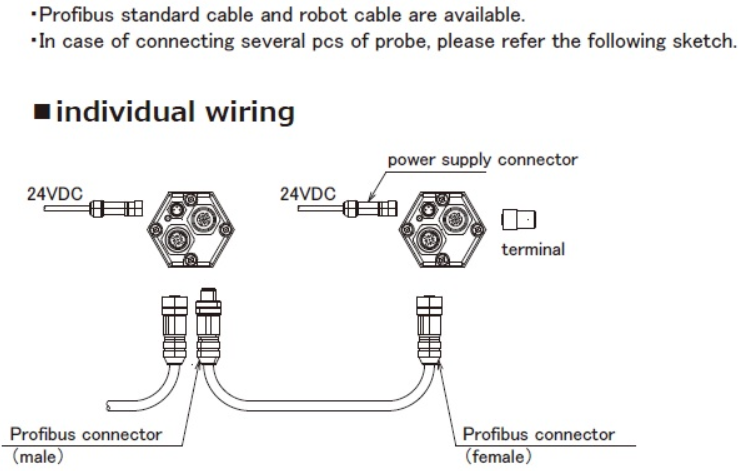

■Connector and Cable Models

・Power supply connector

:CN-SEP-M8-□

・Profibus connector (IN, male)

:CN-SEP-M12M-○□-△

・Profibus connector (OUT, female)

:CN-SEP-M12F-○□

・Terminal

:CN-SEP-TR

○ :cable length(m),

S :standard

R :robot cable

□ :cable length(m)

In case of “0”, it means loose connector only

△ :Connector

blank :loose connector ( IN, male )

M12F:with connector ( OUT, female ) at the other end

( Need to specify cable length )

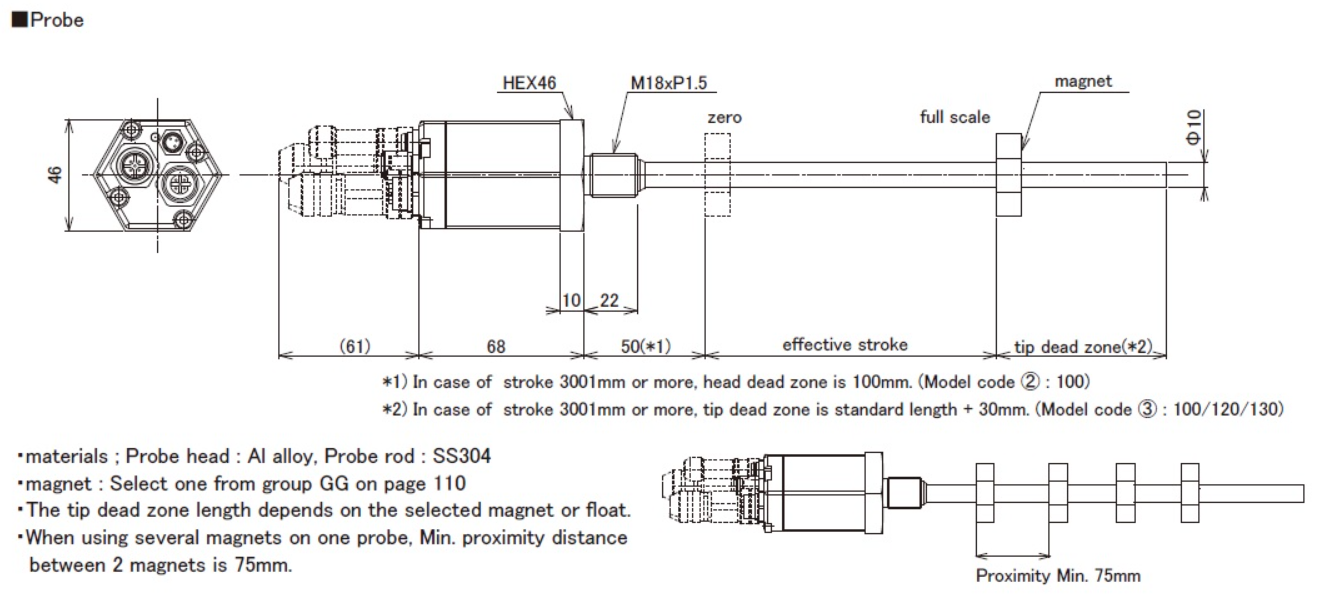

Dimensions

Probe

Profibus Connector