THING TECH CO., LTD.

Thing Tech Besta Power

Manufacturer: THING TECH CO., LTD.

Besta Power

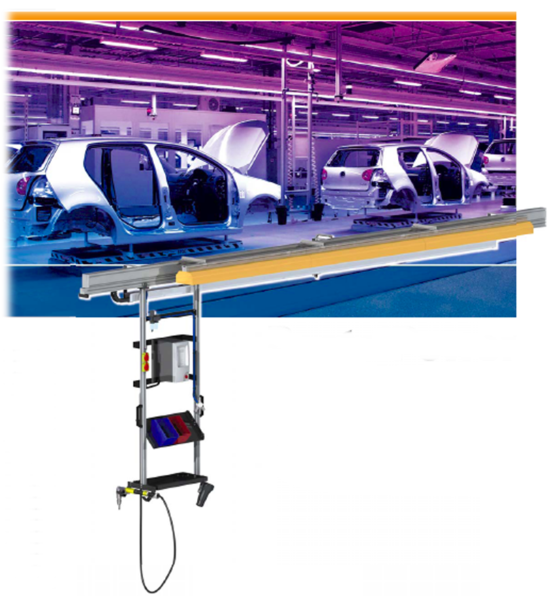

Reduce CO₂ emissions in assembly-line air piping!

No limitations on operating range! Smooth and effortless movement

VestaPower is a product of Conductix Wampfler (Germany).

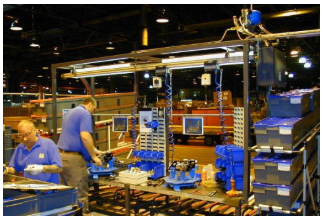

It is highly effective for the manufacturing industry in general, including automobile manufacturers.

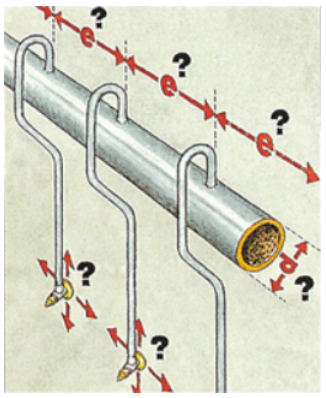

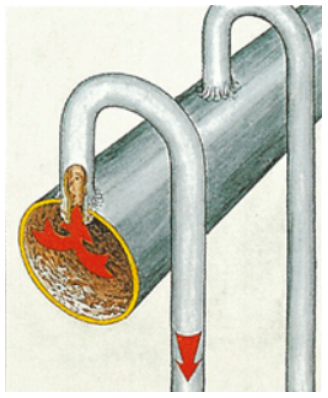

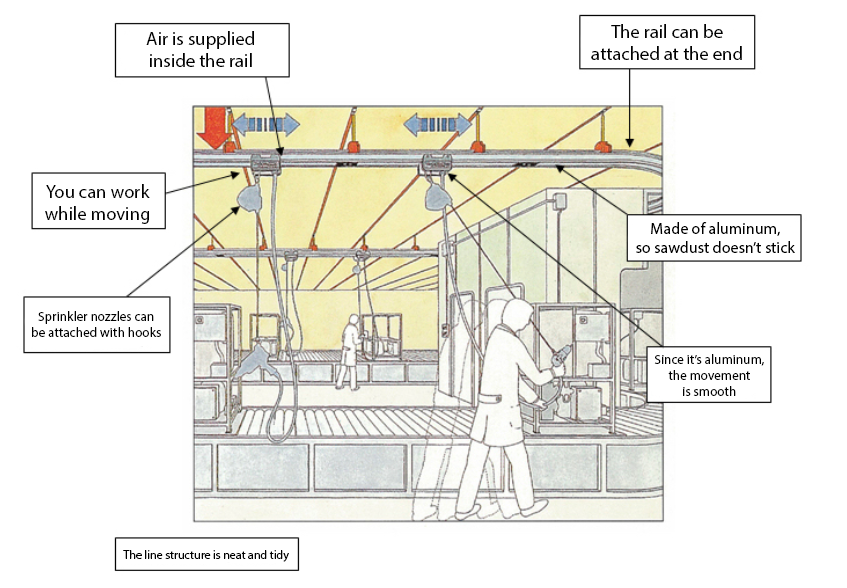

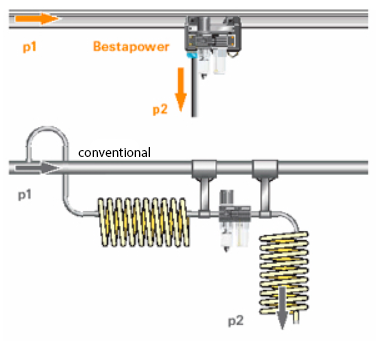

The key feature of this product is that the compressed air pipe itself serves as the traveling rail, and thanks to the development of the air trolley (a movable air outlet), it provides unrestricted movement and excellent operability.

Traditionally, equipment design was complex, and when using air tools, workers were forced to operate within a limited motion range.

With VestaPower, however, smooth and stress-free movement greatly improves work efficiency.

It provides an ideal environment where operators can work comfortably and ergonomically without strain.

Additionally, even if future equipment modifications are required, layout changes can be made easily, keeping investment costs minimal.

Furthermore, by installing ergonomically designed workstations on the traveling rail, users can expect significant benefits such as improved workability, defect prevention, and enhanced safety.

We offer a detailed introduction to VestaPower, a solution that aims for carbon neutrality by reducing CO₂ emissions through improved air piping in assembly processes.

Energy Supply System for Manufacturing Lines – Besta Power

- Air-supply rail

- Power supply system

- Modularization using aluminum profiles

Would you like to streamline your assembly process?

Reducing air consumption helps lower CO₂ emissions.

Additionally, the recycling benefits can reduce your investment costs.

About the Details of BESTA Products

Conventional System

|  |  |  |

| It is difficult to calculate the air supply volume and air consumption. | Both hose routing and tool-hanging rails are required. Additionally, construction work is needed to extract air. | Hoses get tangled, making the workspace cluttered. | Drainage and clogging problems occur. |

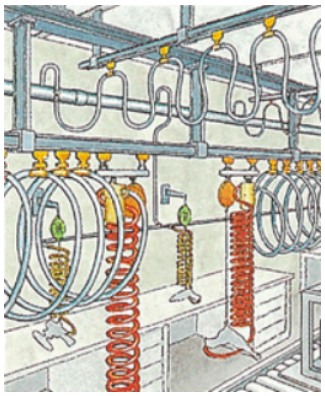

When Using BESTA POWER (Besta Power)

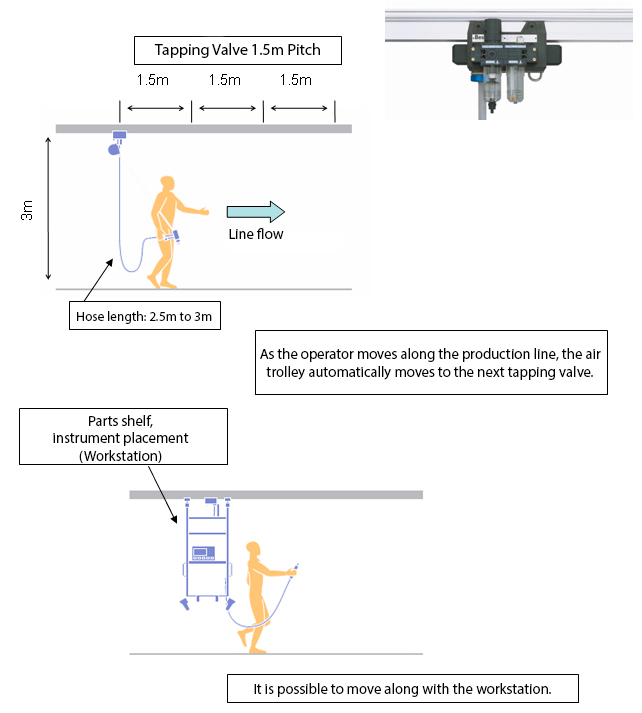

BESTA POWER (Besta Power) Usage Example (Tapping Valve Method)

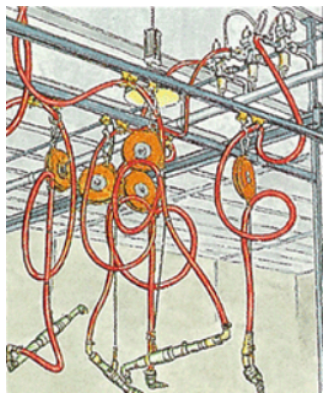

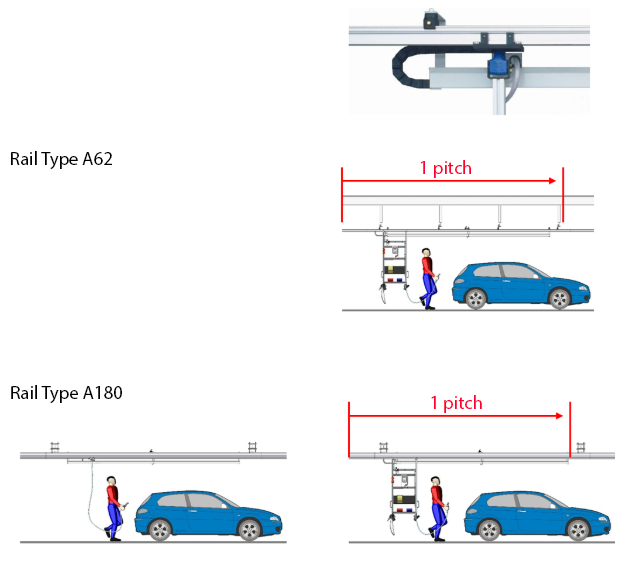

BESTA POWER (Besta Power) Usage Example (Energy Chain Method)

Note: The energy supply system allows movement for 1 pitch with a vehicle.

Energy Cost Reduction and CO2 Emission Reduction

By using BESTA, pressure loss caused by the spiral hose is reduced, which helps to lower the required power of the compressor.

As a result, cost reduction and CO2 emission reduction, as shown below, are possible.

| Pressure Loss in the Tool | 300 L/min | 400 L/min | 600 L/min |

|---|---|---|---|

| A) Besta Power Energy Supply System Hose ½”, 10m + Connection | 0.08 MPa | 0.13 MPa | 0.27 MPa |

| B) Traditional System Spiral Hose Ø11 x 8m + Ø8 x 6m | 0.36 MPa | 0.65 MPa | 1.45 MPa |

| C) Traditional System Spiral Hose Ø8 x 6m + Ø8 x 6m | 0.54 MPa | 0.91 MPa | 2.10 MPa |

| Basic Information | |||||

|---|---|---|---|---|---|

| Energy Cost: Operating Hours per Year: Air Pressure: | ¥15.75/kWh 1800 hours (3 shifts) 0.6 MPa | ||||

| Tool Air Consumption | 300 l/min | 400 l/min | 600 l/min | ||

| A) Energy Transport System Hose ½”, 10m + connection | ¥16,330 | ¥35,381 | ¥110,225 | ||

| 1’036.80 kWh/y | 2’246.40 kWh/y | 6’998.40 kWh/y | |||

| B) Conventional System Spiral hose Øi 11 x 8 m + Øi 8 x 6 m | ¥73,484 | ¥166,018 | ¥575,619 | ||

| 4’665.60 kWh/y | 10’540.80 kWh/y | 36’547.20 kWh/y | |||

| C) Conventional System Spiral hose Øi 8 x 6 m + Øi 8 x 6 m | ¥110,225 | ¥247,666 | ¥898,128 | ||

| 6’998.40 kWh/y | 15’724.80 kWh/y | 57’024.00 kWh/y | |||

| A) and B) Difference over 5 Years | Cost | Energy | CO2 | ||

| ¥285,768 | 18’144.00 | 11’612.00 | |||

| ¥653,184 | 41’472.00 | 26’542.00 | |||

| ¥2,326,968 | 147’744.00 | 94’556.00 | |||

| A) and C) Difference over 5 Years | Cost | Energy | CO2 | ||

| ¥469,476 | 29’808.00 | 19’077.12 | |||

| ¥1,061,424 | 67’392.00 | 43’130.80 | |||

| ¥3,939,516 | 250’128.00 | 160’081.90 | |||

Used for the following purposes

- Rail for the power source of air tools in assembly factories

- Positioning in processing lines

- Air source for robots, etc.

- Rail system for oil spraying

- Mobile assembly tables

- Supply of medical oxygen and other gases

|  |  |  |

| Air Brake Assembly | Diesel Engine Manufacturing Process | Aerospace Industry | Forklift Manufacturing |

|  |  |  |

| Automobile Assembly | Rail Vehicle Assembly Plant | Parts Assembly Workshop | Refrigerated Vehicle Manufacturing |