THING TECH CO., LTD.

Thing Tech PASC Series Balance Cylinder Series Air Balancer

Manufacturer: THING TECH CO., LTD.

Model: PASC Series

AIR BALANCER

Simple! Light! Maintenance-Free!

An Air Balancer is a wire-winding balancer that operates solely on air pressure. It can lift and transport objects from 25 kg to 318 kg using only the force of the air.

Because it is made specifically as a balancer, it has low sliding resistance and is ideal for working while holding the workpiece by hand. It is also inexpensive, helping to save on capital investment costs.

Used in These Applications

- Loading assistance device for assembly plants

- Loading and unloading at logistics centers, etc.

- Weight assistance for heavy parts in parts factories, etc.

- Air Hoist

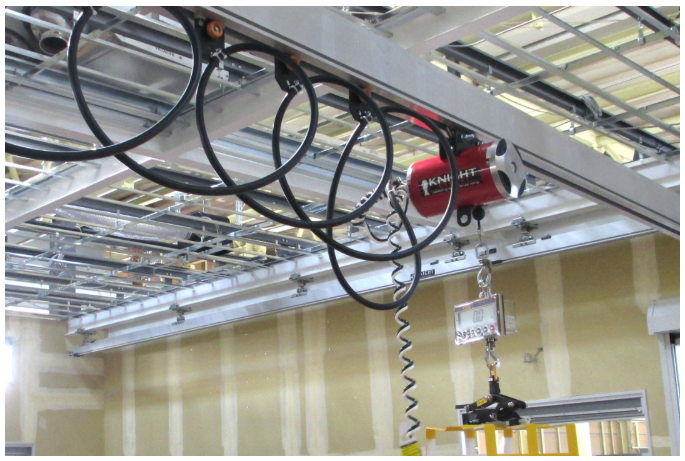

|  |  |  |

| Aluminum Rail & Air Balancer | Air Balancer & Cardboard Clamp | Roll Material Transfer |

Air Balancer

The Air Balancer is a drum type device that operates solely on air pressure. It has a load capacity ranging from 25 kg to 318 kg.

By selecting various “Balance Controls,” such as the lifting/lowering type or balance operation, the device can be configured to suit the customer’s working environment.

In balance operation, work can be performed according to the operator’s hand movements rather than using buttons. With the lifting/lowering pendant, after releasing the Up/Down buttons, the operator can still perform slight lifting or lowering by hand.

Because it is made specifically as a balancer, it has low sliding resistance and is ideal for working while holding the workpiece by hand.

It is also inexpensive, helping to save on capital investment costs.

Knight Global’s Air Balancer product line is the industry’s broadest product lineup.

It is offered in many configurations, including single and tandem setups.

Air Balancers are available in cable type and chain type.

The cable is carbon steel 6 (strand) x 31 (wire) galvanized independent wire rope core (GIWRC), manufactured according to US military specification (DMS-2192E).

For lifting and lowering weights exceeding 150 kg, the chain type is recommended due to the greater durability of the chain.

Knight Chain Balancers use a custom-grade lifting chain that has been specially treated to extend its lifespan by up to 300%.

- Lower sliding resistance compared to conventional cylinder-based balance operation.

- Preparation is easy because the power source is air only.

- Being a drum type, a long stroke can be achieved in a small amount of space.

- Full auto-balance is available, allowing for the lifting of various weights under the same gravity!

- Torque adjustment can be done with just one screwdriver.

Balance Cylinder Series

The Balance Cylinder Series is an air balancer that enables smooth lifting and lowering operations for heavy objects.

This series allows the operator to hold the workpiece directly and perform light lifting and lowering.

Because the operation is extremely smooth, the workpiece will not experience “knocking” during lifting or lowering.

It can be widely used for assembly and transfer work, such as quietly setting down a workpiece on the floor, or for subtle positioning.

This balancer is optimal for tasks like “Gently assembling a workpiece while holding it!” and “Gently setting down a workpiece while holding it!”

Overview

(Callout) Operates with just one air line!

This is a balancer that allows the operator to hold the workpiece directly and perform light lifting and lowering.

Because the operation is extremely smooth, the workpiece will not experience “knocking” during lifting or lowering. It can be widely used for assembly and transfer work, such as quietly setting down a workpiece on the floor, or for subtle positioning.

Gently assembling a workpiece while holding it! Gently setting down a workpiece while holding it! This is the optimal balancer for these tasks.

|  |  |

Specifications / Models

| Type | Weight Setting Method | Model | Lifting Load (N) | Mass (kg) | ||

|---|---|---|---|---|---|---|

| 0.4 MPa | 0.5 MPa | 0.7 MPa | ||||

| Cylinder Type [Vertical Model] | Manual Setting Automatic Setting | PASCO-32V-****-** | 260 | 330 | 460 | 8 |

| PASCO-50V-****-** | 640 | 800 | 1120 | 10 | ||

| PASCO-80V-****-** | 1800 | 2250 | 3150 | 15 | ||

☆ Mass when the stroke is 200 mm.

[Cylinder Type Offset Model Allowable Eccentric Load]

The offset type is designed to accommodate eccentric loads, so the lifting/lowering arm is flange-mounted, and this shows the eccentric load value allowed by this flange.

For example, 200 N in the case of PASCO-32G means that it is possible to lift a weight of 200 N at a position 1 m away from the center of gravity of the suspension.

Furthermore, at a position of 0.5 m, the load is 400 N, and the maximum lifting load is 455 N (including the arm, jig, and workpiece).

Operating Principle

Weight Setting Type (In the case of 2 set weights)

This type is effective for tasks such as attaching, balancing, lifting/lowering, positioning, or detaching several types of workpieces with fixed weights.

| 1 | 2 | 3 | 4 |

|---|---|---|---|

|  |  |  |

| Set the changeover button to 1, and adjust Knob 1 so that the jig is balanced by itself. You can then gently lift and lower the jig while holding it. | After attaching the workpiece, set the changeover button to 2, turn Knob 2, and adjust the setting so that the jig and the workpiece are balanced. | You can gently lift and lower the jig or the workpiece while holding it. | Gently set the jig or the workpiece down, and set the changeover button back to 1. You can then remove the workpiece, returning to the balance setting for the jig only. |

Automatic Weight Setting Type (In the case of Standard Balance Method B)

For multiple workpieces of different weights, the balance setting is adjusted by measuring their weight each time they are lifted.

| 1 | 2 | 3 | 4 |

|---|---|---|---|

|  |  |  |

| Attach the jig and adjust the knob so that the jig is balanced by its own weight and can be gently lifted and lowered while holding it. Lower the jig while holding it, and set it down (to ground level). | Place the workpiece onto the jig, continue pressing the Up button, and release the button at an appropriate height. Since the jig and workpiece are held at that position, transport them while holding the jig or workpiece. | After moving the workpiece to the designated position, press the Balance button to enter the balanced state, and you can then gently lift and lower the jig or workpiece while holding it. | Gently set the jig or workpiece down, and continue pressing the Down button so that you can remove the workpiece. After removing the workpiece, press the Balance button to balance the jig only, and you can then gently lift and lower the jig while holding it. |

Alternative Balance Methods

| Balance Method | Operation Method |

|---|---|

| U (Up) | Press the Up button to lift the workpiece, release the button, and after 0.5 seconds, it automatically enters the balanced state, allowing you to gently lift and lower the jig or workpiece while holding it. |

| D (Down) | Press the Down button and release it, and after 0.5 seconds, it automatically enters the balanced state, allowing you to gently lift and lower the jig or workpiece while holding it. Next, set the jig or workpiece down while holding it, and continue pressing the Down button to remove the workpiece. |

Example of Air Circuit for Manual Weight Setting Type

.The balance setting for the Manual Weight Setting Type is performed by supplying pressure, created by the regulator, to the PL board.

We propose the air circuit examples below, and request that customers prepare a circuit that meets their desired specifications.

1 Set Weight Setting

Used by switching between 0kg balance and a fixed weight setting using the changeover valve.

2 Set Weights Setting

Used by switching between 2 types of weight settings using the changeover valve.

3 Set Weights Setting

Used by switching between 3 types of weight settings using push buttons.

Multiple Weight Settings

Uses an electro-pneumatic regulator, switching between multiple weight settings via an electrical signal input to it.

Outline Drawing

Unit: mm

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PASCA-32V- [Stroke] | 15.5 | 58 | 37 | 90 | 182 | 269 | 82 | 115 | 40 | 20 | 19 | 25 | 200 | 19.5 | M10x1.25 |

| PASCA-50V- [Stroke] | 20 | 58 | 52 | 124 | 264 | 391 | 102 | 127 | 44 | 20 | 30 | 30 | 200 | 28 | M18x1.5 |

| PASCA-80V- [Stroke] | 30 | 115 | 45 | 131 | 325 | 574 | 150 | 135 | 50 | 20 | 35 | 30 | 250 | 36 | M22x1.5 |

| PASCM-32V- [Stroke] | 15.5 | 58 | 37 | 90 | 182 | 269 | 82 | 57 | 40 | 20 | 19 | – | – | 19.5 | M10x1.25 |

| PASCM-50V- [Stroke] | 20 | 58 | 52 | 124 | 264 | 391 | 102 | 57 | 44 | 20 | 30 | – | – | 28 | M18x1.5 |

| PASCM-80V- [Stroke] | 30 | 115 | 45 | 131 | 325 | 574 | 150 | 78 | 50 | 20 | 35 | – | – | 36 | M22x1.5 |

Application Example

Smooth Movement

A calibration weight is gently placed on a scale to check the quality of the scale. This is effective when slow and smooth lifting and lowering is desired.

Model Designation Method

[Cylinder Type] PASCM-32V-500-2-G2

| Weight Setting Method | |

|---|---|

| Symbol | Weight Setting Method |

| PASCM | Manual Setting |

| PASCA | Automatic Setting |

| <Vertical Model> Cylinder Size | |

|---|---|

| Symbol | Cylinder Diameter (mm) |

| 32V | 32 |

| 50V | 50 |

| 80V | 80 |

| Required Stroke (50 mm increments) | |

|---|---|

| Symbol | Required Stroke (mm) |

| 100 | 100 |

| ~ | ~ |

| 1000 | 1000 |

| 1050 and above is custom order | |

| In the case of PASCM (※Option) | |

|---|---|

| Symbol | Number of Balance Set Weights |

| 0 | No Option |

| 1 | 1 Weight |

| 2 | 2 Weights |

| 3 | 3 Weights |

| 4 and above is custom order | |

| Symbol | Switch Type | PASCM Usage (Balance Setting Switch) | PASCA Usage (Operation Method Switch) |

|---|---|---|---|

| G2 | 2-Button Grip Switch | Switches Balance Settings 1, 2 | Operation Method U, or D |

| G3 | 3-Button Grip Switch | Switches Balance Settings 1, 2, 3 | Operation Method U, D, or T (3rd Method) |

PASCM Balance Switching Box (Option)

| 1 Weight | 2 Weight | 3 Weight |

|---|---|---|

|  |  |

| Connected directly to the weight sensing valve | Box Dimensions 75 x 150 x 45 mm (excluding protrusions) | Box Dimensions 75 x 222 x 45 mm (excluding protrusions) |

Operation Switch (Option)

| Grip Switch (with 1000 mm Straight Tube) |

| 2-Button (G2) 46 x 47 x 138 (Dimensions in mm) |

|

| 3-Button (G3) 56 x 47 x 138 (Dimensions in mm) |

|

Performance Specifications

| Type | Cylinder | |

|---|---|---|

| Model | PASC | |

| Features | Workpiece Lifting/Lowering by Hand | Possible |

| Installation Ceiling Height | High | |

| Operation Unit Attachment Location | Arbitrary | |

| Inertial Force Sensing | None | |

| Lifting/Lowering Speed (Balance Mode) | 150 mm/sec | |

| 400 N Load Operating Force | 20 N | |

| 1500 N Load Operating Force | 40 N | |

| Operating Feel | Smooth | |

Table of Mounting Part Dimensions by Model Type

— Please refer to the Outline Drawing for details —

Unit: mm

| Size | Mounting Hole | A | B |

|---|---|---|---|

| 32 □ | Ø17 | 20 | 58 |

| 50 □ | Ø17 | 20 | 58 |

| 80 □ | Ø17 | 20 | 115 |

Notes and Safety Mechanism

Please keep the following points in mind, handle the equipment with sufficient caution, and implement secondary or auxiliary safety measures as needed.

⚠️ If the air supply from the source is shut off while the workpiece is suspended, the anti-drop mechanism prevents the workpiece from dropping suddenly. However, if left unattended, it will gradually descend.

⚠️ The anti-drop mechanism only operates when the air is cut off “instantaneously.” If the air pressure gradually decreases due to leaks from faulty piping, the workpiece will descend according to the leakage rate. Therefore, please take sufficient care to protect the air supply and piping.

⚠️ If tubes around the weight sensing section or control box are cut (or detached), and the air pressure drops or stops, the workpiece will descend according to the air leakage rate. Therefore, please exercise sufficient caution in protecting tubes and other components.

⚠️ If the suspended jig or workpiece detaches while the air is being supplied, the tip of the balancer will spring upward. Therefore, please ensure that the jig and workpiece are securely attached to prevent them from coming loose.

⚠️ Please supply the air used in a dry state, free from moisture, oil, or other contaminants.

Business Items

| Air Balancer | T-Arm |

| Aluminum Rail | Steel Rail |

| Bestapower | |

| Various Assisting Devices | Conveying/Transport Equipment |

| Dust Collection Equipment | Recycling Plants |