Japan, Tokyo Ko-on Denpa

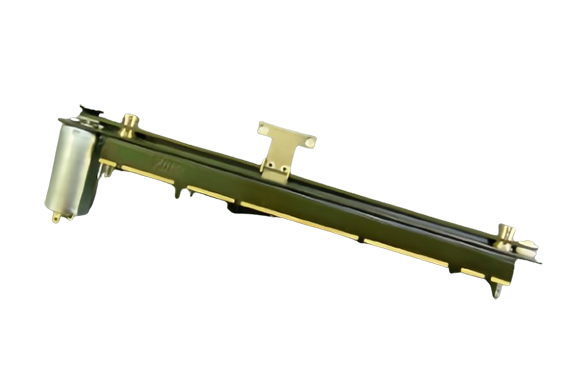

Tokyo Ko-on Denpa MLA Series Motorized Control Fader

Made in Japan

Manufacturer: Tokyo Ko-on Denpa Co., Ltd.

Model: MLA Series

Features

Direct print resistor element used (Special surface treatment).

Vertical style control-bar design.

PCB Terminal style.

All models include a touch sense track.

Electrical Specifications (Initial Value)

| Electrical specifications (initial value) | MLA Series | |

|---|---|---|

| Products | MLA-1100-B*-M8V | MLA-6100-B*-M8V |

| Number of circuits / Type of output laws | 1 Linear taper | |

| Circuit method | Potentiometer circuit | |

| Total resistance (1-3) | 10kohm, 5kohm | |

| Total resistance tolerance | ±20% | |

| Absolute linearity | ±5% (The travel is divided into 10 sections and 11 positions are measured.) | |

| Residual voltage (1-2), (2-3) | 20mV or less | |

| Residual resistance (1-2), (2-3) | 50ohm or less (Reference values) | |

| Touch sense track contact resistance | 30ohm or less (Between terminal T and Control-bar.) | |

| Voltage proof | 1 Min. at AC100V | |

| Insulation resistance | 50Mohm or more at DC100V | |

| Max rating | 0.2W | |

| Maximum input voltage | DC30V or less | |

| Sliding noise level | 47mV or less (by JIS C 6443) | |

| Sliding life | 100,000 Cycles Min. (18cycles/min, Sliding noise level: Less than 100mV) | |

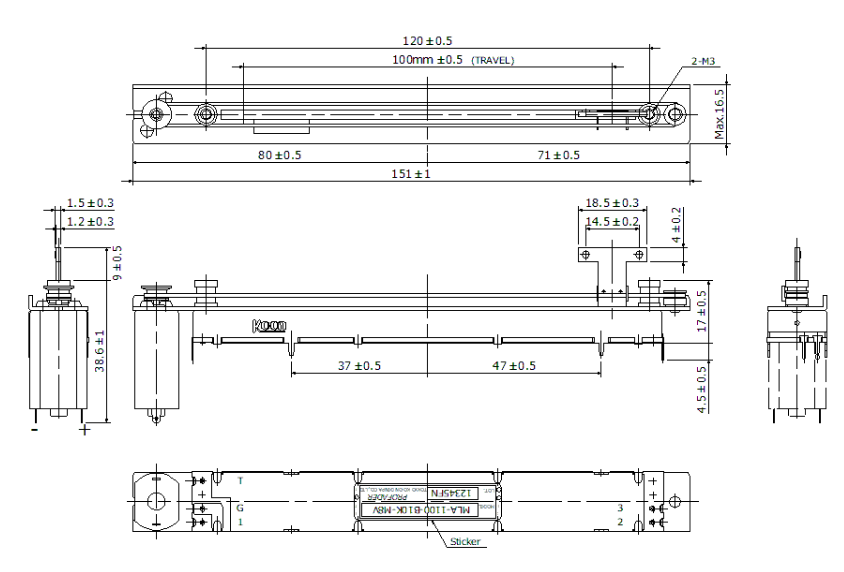

| Drive motor data | DC8V Iron cored motor : Input voltage: DC5V – 11.5V (Nominal DC8V), Stall current: 0.5A or less [FF-050SB-09250 : MABUCHI MOTOR Co., Ltd.] | |

Mechanical Specifications (Initial Value)

| Mechanical specifications (Initial value) | MLA-1100 Series | MLA-6100 Series |

|---|---|---|

| Travel (Stroke) length | 100mm ±0.5mm | 60mm ±0.5mm |

| Operating force | 0.1 to 0.4N | |

| Strength Nut-Attached | 100Ncm | |

| Attached parts | M3 screw (Length: Panel thickness + 3~5mm) | |

| Stopper strength | 30N | |

| Push-pull strength | 30N | |

| Alignment to the center | ±0.5mm (State not to pressure control-bar, Measurement position: Mounting surface) | |

General Specifications

| General specifications | MLA Series |

|---|---|

| Temperature range | 0 to +50 degrees C (Operating), -10 to +60 degrees C (Storage) |

| Relative humidity | 80%RH (No condensation) |