Bending, Japan, Toyo Kensetsu Kohki

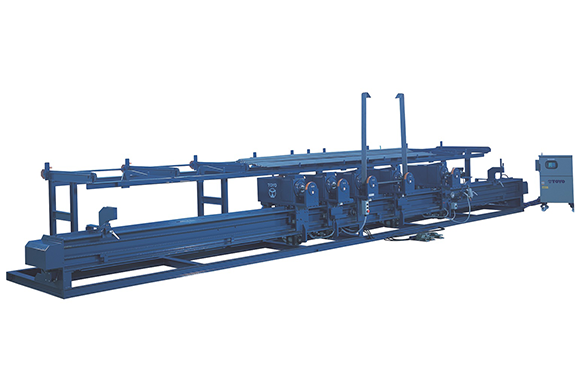

TOYO KENSETSU KOHKI TBS-25-1 AUTO REBAR BENDING

Products Made in Japan

Manufacturer: TOYO KENSETSU KOHKI

Model: TBS-25-1

Features

- AUTO REBAR BENDING

- Bar (Small)

- Bar (Large)

- Reduce manpower

- Mass production

- Rebar fabrication

- Precast concrete

| Model | TBS-25-1 |

|---|---|

| Capacity | SD345: D10-9 ~ D25-1 SD390: D10-9 ~ D25-1 |

| Required breaker capacity | 30A |

| Bending unit revolution | 6.0/7.2rpm (50/60Hz) |

Machine & Processing

Specifications

| Specifications | TBS-25-1 (10m) |

| Required breaker capacity | 30A |

| Min, distance between fulcrum centers | 265mm(No.3-4) |

| Max. distance between fulcrum centers | 9,440mm(No.1-5) |

| Bending angle | 15~180° |

| Bending unit revolution | 7.2 rpm(50/60Hz) |

| Total motor capacity | 9.75kW (including air-compressor) |

| Dimensions (LXWXH) | 10,180×2,100×1,605mm |

| Total weight | 4,380kg |

Similtaneous Max. Bending Quantity (pcs)

| Rebar diameter | D10 | D13 | D16 | D19 | D22 | D25 |

| Fulcrum roller dia. | Φ39 | Φ52 | Φ62 | Φ73 | Φ84 | Φ94 |

| SD345 | 9 | 7 | 5 | 2 | 1 | 1 |

| SD390 | 9 | 7 | 4 | 2 | 1 | 1 |

Details

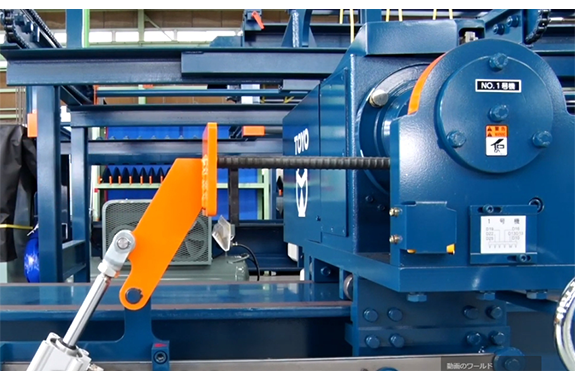

・TBS-25-1 is an automatic rebar bending machine which is exclusively for bending D16~D25.

※ D10, D13 is also bendable.

・TBS-25-1 is most suitable for bending shapes for foundations, closed stirrups, stirrups with multiple angles and double anchors.

・TBS-25-1 is also useful for bending long length of D19~D25 used in the civil engineering work.

・Shapes can be easily set on the user-friendly touch screen.

・Touch screen is placed in the middle, which raises working efficiency.

・Number counter device is optional.”

Other items of TOYO KENSETSU KOHKI

Request the quotation for TOYO KENSETSU KOHKI

Related Products

-

Yutani D, DH Impact Screwdrivers (Straight Standard Type/Corner Standard Type)

-

Chiyoda Seiki RF-400P Medium Flow Rate, Self-powered Pressure Regulator/Large Flow Rate, Pilot Type Pressure Regulator (Primary pressure: 0.2 MPa or less/adjustment pressure 0.003 to 0.02 MPa, standard flow rate: 150 m3/h・Air)

-

Nippon Chemical Screw PEEK/MFH(M-L) PEEK/Micro (+) flathead machine screw

-

Atom Kousan ATD-35A Dust Miel

-

KONAN MAGSTER ⅡF AVS2-08 5 Port Air Operated Valves Gasket-connected Return Type

-

Hammer Caster 435SOS-RB Rubber Wheel