Cutting, Japan, Toyo Kensetsu Kohki

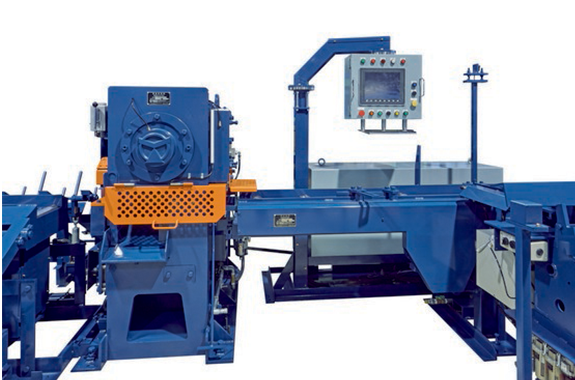

TOYO KENSETSU KOHKI TFC-LAV AUTO REBAR CUTTING

Products Made in Japan

Manufacturer: TOYO KENSETSU KOHKI

Model: TFC-LAV

Features

- AUTO REBAR CUTTING

- Bar (Small)

- Bar (Large)

- Reduce manpower

- Mass production

- High strength rebar processing

- Rebar fabrication

- Precast concrete

| Model | TFC-LAV |

|---|---|

| Capacity | SD345: D10-25 ~ D41-1 SD390: D10-25 ~ D41-1 SD490: D10-25 ~ D41-1 |

| Required breaker capacity | 100A |

| Cutting blade width | 300mm |

Machine & Processing

Speciffications

| Specifications | TFC-LAV (10 * 12) |

| Required breaker capacity | 100A |

| Applicable length of raw material | 3,500~12,000mm |

| Cutting length range | 500~10,000mm Discharging at specified position can be conducted from 1,250mm. |

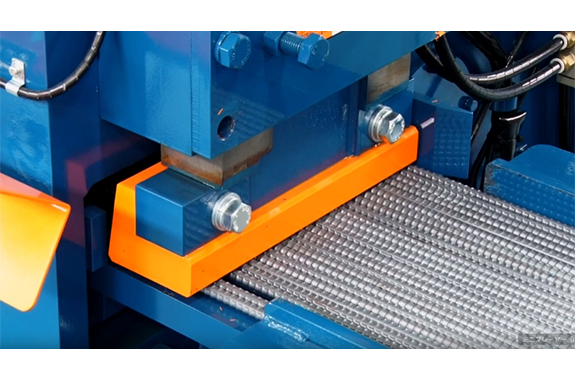

| Cutting blade width | 300mm |

| Conveyor effective width | 275mm |

| Material feeding speed on conveyor | High speed: 54.0m/min Low speed: 27.0m/min (50/60Hz) |

| Total motor capacity | 14.65kW (including air-compressor) |

| Dimensions (LXWXH) | 24,160 * 4070 * 1 ,600mm |

| Total weight | 12,410kg |

Simultaneous Max. Cutting Quantity (pcs.)

| Rebar diameter | D10 | D13 | D16 | D19 | D22 | D25 | D29 | D32 | D35 | D38 | D41 |

| SD345 | 25 | 19 | 15 | 12 | 10 | 9 | 6 | 5 | 4 | 3 | 1 |

| SD390 | 25 | 19 | 15 | 12 | 9 | 7 | 5 | 4 | 3 | 2 | 1 |

| SD490 | 25 | 19 | 15 | 11 | 8 | 6 | 4 | 3 | 3 | 2 | 1 |

Details

・TFC-LAV is an automatic rebar cutting machine, which is capable of cutting and storing rebars in a large quantity.

・Length to cut can be set by 1mm.

・Dimension can be easily set on the user-friendly touch screen.

・It is easy to set cutting optimization and where to discharge after-cut-bars.

・Combination cutting of 2 kinds of length can be done from raw materials.

・3 types of conveyor length are available; 8m(Feed-out side)x 9m (Feed-in side), 10mx 10m, 12mx 12m.

・In combination with automatic sorting and feeding device :TAS-II or TS-V, TFC-LAV can carry out material handling efficiently.

・Cutting blade width is 300mm, which enables you to cut 25 pieces of D10 at time.

・Number counter device is optional.”

Other items of Toyo Kensetsu Kokhi

Request the quotation for Toyo Kensetsu Kokhi

Related Products

-

Tsugaru Kogyo No.4131 (1.1m) / 4132 (1.5m) / 4133 (2.0m) Tora Iron Pile 1.1m/1.5m/2.0m

-

Super Tool RN1012-4650 Double-Size Ratcher Wrench (Reversible Claw Type)

-

Vessel No.SST5P SAKISUBO Torsion Bit 10-Piece Set

-

NPK Scaling Hammers

-

Vessel No.GT-P4.5DR Air Screwdriver Impact Type

-

DIJET SDHW1504ADFN-W2 Insert For FJM/FJM-F4 Type