Cutting, Japan, Toyo Kensetsu Kohki

TOYO KENSETSU KOHKI TFC-M-H AUTO REBAR CUTTING

Products Made in Japan

Manufacturer: TOYO KENSETSU KOHKI

Model: TFC-M-H

Features

- AUTO REBAR CUTTING

- Bar (Small)

- Bar (Large)

- Reduce manpower

- High strength rebar processing

- Noiseless spec.

- Rebar fabrication

- Precast concrete

| Model | TFC-M-H |

|---|---|

| Capacity | SD390: D10-16 ~ D38-1 SD490: D10-16 ~ D38-1 |

| Required breaker capacity | 75A |

| Cutting blade width | 190mm |

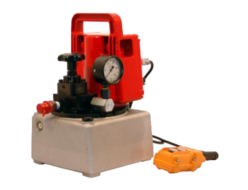

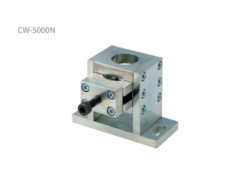

Machine & Processing

Speciffications

| Specifications | TFC-M-H (10×12・MC-51W) |

| Required breaker capacity | 75A |

| Applicable length of raw material | 3,500~12,000mm |

| Cutting length range | 1,050~10,000mm When product discharging unit is not attached ; 500mm~ When stopper for short dimension is attached; 300mm~ (Optional) |

| Cutting blade width | 190mm |

| Conveyor effective width | 185mm |

| Material feeding speed on conveyor | 54.0/64.7 m/min (50/60Hz) |

| Total motor capacity | 8.35kW(including air-compressor) |

| Dimensions (LXWXH) | 23,200×2,650×1,450mm |

| Total weight | 5,900kg |

| Rebar diameter | D10 | D13 | D16 | D19 | D22 | D25 | D29 | D32 | D35 | D38 |

| SD390 | 16 | 12 | 10 | 7 | 5 | 4 | 3 | 2 | 1 | 1 |

| SD490 | 16 | 12 | 10 | 5 | 4 | 3 | 2 | 2 | 1 | 1 |

Details

・When you consider automation into rebar cutting, let us introduce TFC-M-H.

・TFC-M-H turns the hard work of material handling and discharging into an automatic way.

・TFC-M-H is equipped with a special conveyor, which reduces the noise in feeding material.

・Rebar cutter Model : MC-51 is equipped.

※TFC-M-H is capable of cutting up to D38 with SD490(Yield Point: 490-625N/mm2, Tensile Strength≧620N/mm2).

・Cutting blade width is 190mm, which enables you to cut 10 pieces of D10 at at time.

・3 types of conveyor length are available; 8m(Feed-out side)x 9m (Feed-in side), 10mx 10m, 12mx 12m. ”