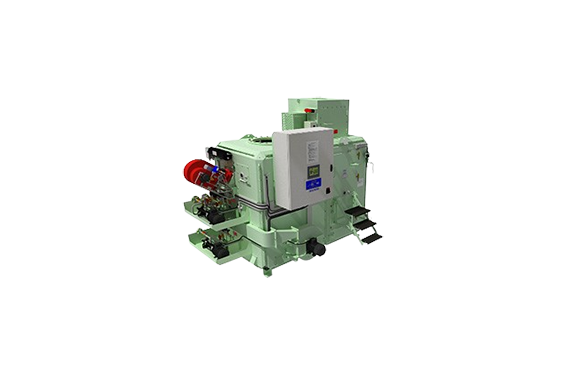

Tratec Limited OG Series, GS Series Incinerator

Manufacturer: Tratec Co., Ltd

Model: OG Series: OG120, OG200, OG400 ; GS Series:GS500 ,GS900 ,GS1000

Features

OG120 Models

- The smallest incinerator in the TEAMTEC range, up to 190.000 kcal/h (220 kw). Its robust, compact design and high performance make the OG120 model the perfect first choice for waste treatment on board small and medium sized vessels.

OG200 Models

- With its robust, compact design and high performance, the OG200 is one of the most popular models in the TEAMTEC product range and the obvious first choice for solving waste disposal on medium sized vessels. With a thermal capacity of up to 400.000 kcal/h (465 kW).

OG400 Models

- With its robust, compact design and high performance, the OG400C is one of TEAMTEC’s most popular models and the perfect choice for solving waste disposal on medium-sized vessels. With a capacity of up to 512 000 kcal/h (596kW) – up to 81 l/h of sludge oil.

GS500 Models

- Two versions popular for any kind of vessels that have to burn large amounts of sludge oil and solid waste, perfect for vessels with more than 60 people on board. The GS500C has a thermal capacity of up to 731000 kcal/h (850kW) and an IMO defined sludge oil capacity of 100 l/h. Additionally, the GS500CS version has a large top-mounted sluice gate for a continuous supply of around 135 kg/h of solid waste.

These models are recommended for passenger ships, small cruisers and larger warships.

GS900 Models

- The GS900C is one of the most effective, compact and environmentally friendly marine incinerators on the market today. This model is available with manual or automatic feeding of solid waste and fully automatic sludge combustion.

GS1000 Models

- The flagship model, GS1000C, is the most compact 1500 kW marine incinerator on the market today. This model comes equipped with bilge water injection for NOx reduction as standard.

The TEAMTEC bilge water injection system uses the heat from the combustion of sludge oil to reduce the load on the oil-water separator. There is no additional diesel oil consumption. PLC-controlled water injection ensures:

Safe disposal of contaminated water

Increase sludge capacity by 10%

Reduced NOx emissions (verified by DNV)