Japan, UHT CORPORATION

UHT CORPORATION MPRO-□□□□□inP series Multi Product Punching Machine +Punch unit

Made in Japan

Manufacturer: UHT CORPORATION

Model: MPRO-□□□□□inP series

(MPRO-PUNCHin150/ MPRO-PUNCHin200/ MPRO-PUNCHin150P/ MPRO-PUNCHin200P/ MPRO-DIEin150/ MPRO-DIEin200

MPRO-DIEin150P/ MPRO-DIEin200P/ MPRO-SELECTin150/ MPRO-SELECTin150P/ MPRO-SELECTin200P)

Features

- MPRO System Line Ups can offer high productivity by selecting the best combination from the variety style of machines and loader/unloader modules to satisfy any scale of job depending on the purpose.

- Variety of optional unique and functional automatic loader/unloader module is available.

- MPRO System Line Ups can versatilely meet any scale of production from proto-type work to mass-production.

Characteristics

- Combination with Punch units materializes to meet any type of punch patterns.

Standard Specifications Pinch in P

| Model name | MPRO-PUNCHin150 | MPRO-PUNCHin200 | ||

|---|---|---|---|---|

| MPRO-PUNCHin150P | MPRO-PUNCHin200P | |||

| Work | Material | Ceramic Green Sheet | ||

| Form | Sheet | |||

| Thickness | Max. 0.5mm | |||

| Size | Roll width | Max.200mm | Max.250mm | |

| Sheet | Max.□200mm | Max.□250mm | ||

| Punching area | Max.□150mm | Max.□200mm | ||

| Attachment(How to attach) | Supply : Sheet : V/F Work holder, Vacuum frame Roll : Vacuum frame | |||

| Punch | Die set unit | Layout in Max. □70mm | Layout in Max. □120mm | |

| 4 sets of tooling punch(+O.P) | ||||

| PU unit | 6axes(PU-25 In-serve number) An unit selected by you | |||

| Capability | Punching accuracy | ±10μm(Between 2 points in 1″ punched on UHT’s test film) | ||

| Resolution | X-axis Y-axis:1μm | |||

| Punching speed | Die set unit | Die set unit : Max. 600 holes/min + Tooling hole punches(With 1.0mm pitch) | ||

| PU unit | Max.600 hole/min NC punch on PU-25 with 1mm pitch in Y direction | |||

| Feed speed | Max.30m/min(Simultaneous 2-axis control) | |||

| Data | 1file(30000 positions) | |||

| Control function | Control | Controller : UHT made MJUC controller | ||

| Operation | 6.5″ color LCD touch panel | |||

| Punch data | By interactive software on outstanding P/C | |||

| Network | Data transfer from P/C to machine through | |||

| Dust collector | Via Punch : External dust collector Tooling punch : Ejector | |||

| PU unit : Ejector | ||||

| Power | 3φ AC200V±10% 2kVA | |||

| Air | 0.4MPa~0.7MPa | |||

| Machine size | With loader module(Both sides) | W1440×D1200×H1600mm | W1665×D1280×H1600mm | |

| W1990×D1290×H1600mm | W2315×D1470×H1600mm | |||

| Machine mass | Approx.1100kg | Approx.1500kg | ||

| Approx.1350kg | Approx.1750kg | |||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | ||

| Humidity | 40~60%(Non-dewing) | |||

Standard Specifications DIE in P

| Model name | MPRO-DIEin150 | MPRO-DIEin200 | ||

|---|---|---|---|---|

| MPRO-DIEin150P | MPRO-DIEin200P | |||

| Work | Material | Ceramic Green Sheet | ||

| Form | Sheet | |||

| Thickness | Max. 0.5mm | |||

| Size | Roll width | Min.150~Max.200mm | Min.200~Max.250mm | |

| Sheet | Min.□150~Max.□200mm | Min.□200~Max.□250mm | ||

| Punching area | Max.□150mm | Max.□200mm | ||

| Tooling punch | Max.□170mm | Max.□220mm | ||

| Attachment(How to attach) | Supply : Sheet : V/F Work holder, Vacuum frame Roll : Vacuum frame | |||

| Punch | Die set unit | Layout in Max.□150mm | Layout in Max.□200mm | |

| 2 sets of tooling punch (+O.P) | ||||

| PU unit | 6axes(PU-25 In-serve number) An unit selected by you | |||

| Capability | Punching accuracy | ±10μm(Between 2 points in 1″ punched on UHT’s test film) | ||

| Resolution | X-axis Y-axis:1μm | |||

| Punching speed | Die set unit | Die set unit : Max. 600 holes/min + Tooling hole punches (With 1.0mm pitch) | ||

| PU unit | Max.600 hole/min NC punch on PU-25 with 1mm pitch in Y direction | |||

| Feed speed | Max.30m/min(Simultaneous 2-axis control) | |||

| Data | 1file(30000 positions) | |||

| Control function | Control | Controller : UHT made MJUC controller | ||

| Operation | 6.5″ color LCD touch panel | |||

| Punch data | By interactive software on outstanding P/C | |||

| Network | Data transfer from P/C to machine through | |||

| Dust collector | Via Punch : External dust collector Tooling punch : Ejector | |||

| PU unit : Ejector | ||||

| Power | 3φ AC200V±10% 2kVA | |||

| Air | 0.4MPa~0.7MPa | |||

| Machine size | With loader module(Both sides) | W1440×D1200×H1600mm | W1665×D1280×H1600mm | |

| W1990×D1200×H1600mm | W2315×D1470×H1600mm | |||

| Machine mass | Approx. 900kg | Approx. 1100kg | ||

| Approx. 1350kg | Approx. 1600kg | |||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | ||

| Humidity | 40~60%(Non-dewing) | |||

Standard Specifications Select in P

| Model name | MPRO-SELECTin150 | |||

|---|---|---|---|---|

| MPRO-SELECTin150P | MPRO-SELECTin200P | |||

| Work | Material | Ceramic Green Sheet | ||

| Form | Sheet | |||

| Thickness | Max. 0.5mm | |||

| Size | Roll width | Max.200mm | Max.250mm | |

| Sheet | Max.□200mm | Max.□250mm | ||

| Punching area | Max.□150mm | Max.□200mm | ||

| Tooling punch | Max.□200mm | |||

| Attachment(How to attach) | Supply : Sheet : V/ FWork holder, Vacuum frame Roll : Vacuum frame | |||

| Punch | Die set unit | Layout in Max.□150mm | Layout in Max.□200mm | |

| 4 different diameters’ punching holes are settable. | ||||

| 4 sets of tooling punch (+O.P) | ||||

| PU unit | 6axes(PU-25 In-serve number) An unit selected by you | |||

| Capability | Punching accuracy | ±10μm (Between 2 points in 1″ punched on UHT’s test film) | ||

| Resolusion | X-axis Y-axis :1μm | |||

| Punching speed | Die set unit | Die set unit : Max. 600 holes/min + Tooling hole punches(With 1.0mm pitch) | ||

| PU unit | Max.600 hole/min NC punch on PU-25 with 1mm pitch in Y direction | |||

| Feed speed | Max.30m/min(Simultaneous 2-axis control) | |||

| Data | 1file(30000 positions) | |||

| Control function | Control | Controller : UHT made MJUC controller | ||

| Operation | 6.5″ color LCD touch panel | |||

| Punch data | By interactive software on outstanding P/C | |||

| Network | Data transfer from P/C to machine through | |||

| Dust collector | Via Punch : External dust collector Tooling punch : Ejector | |||

| PU unit : Ejector | ||||

| Power | 3φ AC200V±10% 2kVA | |||

| Air | 0.4MPa~0.7MPa | |||

| Machine size | With loader module(Both sides) | W1665×D1280×H1600mm | ||

| W1990×D1200×H1600mm | W2315×D1420×H1600mm | |||

| Machine mass | Approx.1100kg | |||

| Approx.1350kg | Approx.1600kg | |||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | ||

| Humidity | 40~60%(Non-dewing) | |||

Optional

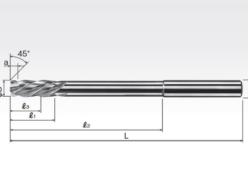

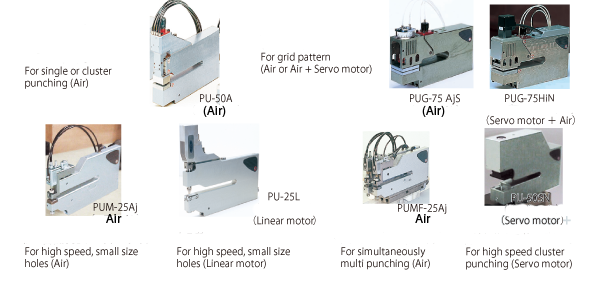

Punch units

Model

| Punching Area(mm)\Unit width(size) | 25 | 50 | 75 | 100 | 125 | 150 |

|---|---|---|---|---|---|---|

| 6inch(□150) | PU-25A06 PU-25Aj06 PUM-25Aj06 PU-25L06S PU-25Lj06S PU-25LH06S PUF-25A06 PUF-25Aj06 PUF-25L06S PUF-25Lj06S PUMF-25Aj06 | PU-50A06 PU-50A06S PU-50BA06 PU-50BA06S PU-50S06S | PU-75A06 PU-75A06S PU-75S06S PUG-75Aj06N PUGD-75Aj06N PUG-75Hj06N | PU-100A06 PU-100A06S PU-100S06S PUG-100Aj06N PUGD-100Aj06N PUG-100Hj06N | PU-125A06 PU-125A06S PU-125S06S PUG-125Aj06N PUGD-125Aj06N PUG-125Hj06N | PU-150A06 PU-150A06S PUG-150Aj06N PUG-150Hj06N |

| 8inch(□200) | PU-25A08 PU-25Aj08 PU-25L08S PU-25Lj08S PU-25LH08S PUF-25A08 PUF-25Aj08 PUF-25L08S PUF-25Lj08S PUM-25Aj08 PUMF-25Aj08 | PU-50A08 PU-50BA08 PU-50BA08S PU-50A08S PU-50S08S | PU-75A08 PU-75A08S PU-75S08S PUG-75Aj08N PUGD-75Aj08N PUG-75Hj08N | PU-100A08 PU-100A08S PU-100S08S PUG-100Aj08N PUGD-100Aj08N PUG-100Hj08N | PU-125A08 PU-125A08S PUG-125Aj08N PUGD-125Aj08N PUG-125Hj08N | PU-150A08 PU-150A08S PUG-150Aj08N PUG-150Hj08N |

※To select proper type of punch unit, make sure if selected machine model provides enough punch units space and proper driving source.

Punch unit classification

| Punch unit | Punch types | ー | Unit/mm | Drive method | Jet air preventing scum riser | Sizes for Workpiece | Unit material |

|---|---|---|---|---|---|---|---|

| PU | M Micro F Flexible (Multi units) G Grid P Plate | ー | 25~150 | A(Air) S(Servo motor) H (Hybrid (Servo motor+ Air)) B(Ball plunger) D(Double cylinder) | j | 06 08 | S (Steel) N (Vibration proof steel) |

Variety range of tooling

Tooling available from single to die set type cluster, grid punching.

CAD interface

Data conversion software from CAD data direct to punching data.

Broken punch detector

Pause the machine running by detecting the punch breakage using I/P.

Punch setter PS-01

Easy tooling alignment with CCD camera and TV monitor for Punch units.

Lift car

For big size of punch unit exchange

Outline Drawing