Japan, UHT CORPORATION

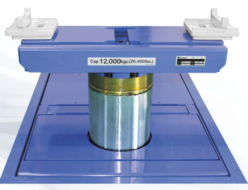

UHT Corporation HCp-1010 series Hole Checker

Made in Japan

Manufacturer: UHT CORPORATION

Model: HCp-1010 series

Applicable to thin materials: ceramic green sheet, etc.

Enabling the measurement and inspection of micro holes, thus contributing to the reduction of percent defective

Capable of inspecting φ50 m holes

Micro-hole inspection with □230mm wide area.

High-speed measurement – 4 seconds.

Characteristics

- Enabling the measurement and inspection of micro holes.

- Quality is judged according to the difference in the take-in master work data.

- Measurement and inspection data can be displayed and stored on a PC. (OP)

- A maximum of 100,000 holes can be checked.

- Quick inspection

- 4 seconds high-speed measurement (under the area at 165×230mm and in undivided mode)

- Easy operation

- Operation is easy with a 10.4-inch LCD graphical touch panel.

- Compact design for easy installation and moving.

-

Standard Specifications

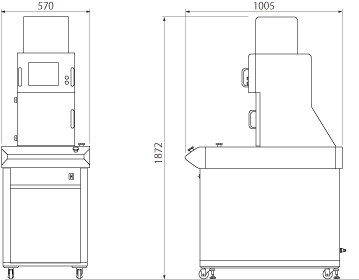

Model name HOLE CHECKER(HCp-1010) Work Work Punched thin materials(Green Sheet, Substrate, etc) Size Max.□250mm Thickness Max.0.5mm Inspecting area Taking without division once: Max.165×230mm Moving method Table Hole Minimum diameter φ50μm(Variation with the range of view) Check, Count Max.100,000 holes ※Variation with the condition Inspecting time Undivided mode: 4.0sec Divided mode: 8.0sec 3-divided mode: 10.5sec

(With 6400 holes and the uppermost level of camera height under the setting of inspection area at □160mm)Movable axis X-axis(Camera Left/Right) Stepping motor Y axis(Table) Z axis(Camera Up/Down) Manual Range of view Max.170mm wide (Height of camera: the uppermost level)

Min.85mm wide(Height of camera: the bottom level)Lighting LED line light(white) Display, Control panel 10.4inch LCD touch panel Safety device Allover hood Power source AC100V ±10% 0.5kVA Machine size W570×D1005×H1872mm Machine weight Approx.260kg Working condition Temperature 10~35℃(22±2℃ recommended) Humidity 40~60%(Non-dewing) Outline Drawing

Options

- External data taking

- Software for HCp data conversion