Japan, UHT CORPORATION

UHT CORPORATION Linear type Multi Punching Machine MP-12□□□L series

Made in Japan

Manufacturer: UHT CORPORATION

Model: MP-12150L / MP-12200L

(Ceramic green sheet, etc. and work like sheet.)

Features

- Super-high speed MP

Super-high speed X and Y axes are installed. Max. 1500 hole/min (with PUM-25L)

Low vibration / Quiet machine

Characteristics

- -A minute hole is processed in super-high speed and super-high accuracy.

- -The initial running cost is decreased by die-less and generalizing punches.

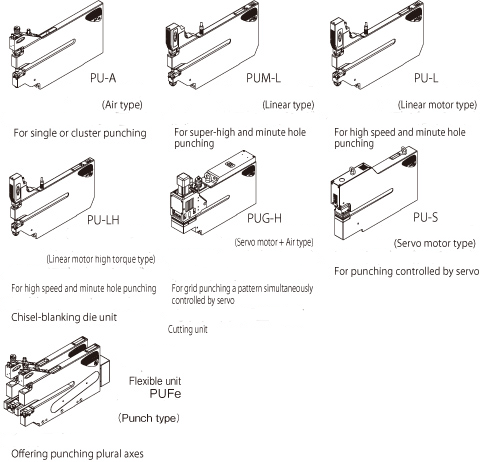

- ・The setting of the unit of a variegated punch and the punching method can be easily done according to the processing pattern and the condition.

・Selectable from abundant punch units, suitable for processing conditions of air and electric type, and from the punch types in a super-minute diameter, a standard hole, gang, and grid, etc. - -Selectable from line-ups corresponding prototype, many varieties small lot, and medium mass production

- Selectable from the combination of a main body modules and various loaders

-

Standard Specifications

Model MP-12150L MP-12200L Work Material Ceramic green sheet,etc.and work like sheet. Thickness Max 0.5 mm Size/Sheet Max □175mm(RC:Max □180mm) Max □225mm(RC:Max □250mm) Punching area Max □150mm Max □200mm How to attach Supply : Sheet : Standard work holder, Vacuum frame

Roll : Vacuum framePunch unit(OP.) Number of installing (in the PU-25 size) 12axes Capability Machining Accuracy ±10μm(Between 2 points in 1″ punched on standard UHT’s test film) Machining Speed By PUM-25L :Max1500hole/min

By PU-25L :Max1000hole/min

By PU-25A :Max 600hole/min

NC punch with 1mm pitch in Y direction on standard V/H work holderSystem Drive method XYaxis linear motor Control function Control UHT made MJUC controller Operation 6.5″ color LCD touch panel Punch data Software on PC (independent of the main body) Number of processing data memories 1 file : Max. 30000 positions Network Transmission of machining data from PC to the machine through LAN.

Centralized monitoring the machine operating condition (up to 4 units) on PCImage Processing method Image data processing is executed by the image processing function with CCD only made of UHT. Power source 3φ AC200V ±10% 3kVA Air source 0.4~0.7MPa Machine size (Body) W 1170mm 1220mm D 1070mm 1200mm H 1400mm 1400mm Machine weight (Body) 約1000kg 約1250kg Working condition Temperature 10℃~35℃ (22℃±2℃ recommended) Humidity 40~60% (Non-dewing) Options

- Punch setter

- Data conversion software from CAD

- Booster tank

- Metal mold (Punch, Die)

- PC

- Punch units

- Power box

- Punch break detecting software

Outline Drawing

Example of floor layout

Related Products

-

Kyowa LTR-S-30KNSA1 LTR-S-SA1 One-end Revolving Tension Load Cell

-

Kyowa CR-20 runout fastener Sensor/Transmitter Accessories

-

YOSHITAKE TA-22ML Air Vent Valve

-

Fukui FK-HP800EX Cam System Handpress

-

Nippon Chemical Screw PC/OH( M-L) PC/(+) round flathead machine screw

-

SENSEZ JW-7000 Waterproof Connector-type Pressure Sensors