Japan, UHT CORPORATION

UHT CORPORATION LS-S208 series Laser Scriber Scan Type Laser

Made in Japan

Manufacturer: UHT CORPORATION

Model: LS-S208 series (Ceramic Substrate(After baking)/Green Sheet/Laminated Material etc. )

Features

- Realizing an ultra-compact machine

Conserve installation space of 0.56m2

Lightening of 650kg.(The installation on the second floor or more in the building is possible.) - High speed and high accurate scribing

Speed:500mm/s Accuracy:±20μm - Maintenance-free, low running cost

Characteristics

- -The ultra compact all-in-one design and easy installation

- The installation area is 0.56m2 with the width of 700mm and the depth of 800mm.

Realizing space-saving installation and easy transfer.

Lightening of 650kg. (The installation on the second floor or more in the building is possible.) - -A high-speed processing with the galvanometer scanner is achieved.

- Scanning area : □50mm

Max. processing area by synchronization with X and Y stages: □200mm - -Variegated scribing functions

- Highly accurate scribing by image processing Straight lines, irregular shapes and circular-arc shapes can be scribed by a dot and a continuous ditch processing.

- -The fiber laser unit of complete air-cooling is installed.

- High stability, maintenance-free The low running cost is achieved without incidental equipment.

- -Accommodating automation (OP.)

- -Safety

- Class-1 laser product in compliance with JIS

Standard Specifications

| Model name | Ceramic Substrate(After baking)/Green Sheet/Laminated Material etc. | ||

|---|---|---|---|

| Work | Material | Ceramic Substrate(After baking)/Green Sheet/Laminated Material etc. | |

| Scribing area | Max.□200mm(The rectangle work is possible.) | ||

| Thickness | Max.5.0mm | ||

| Capability | Positioning accuracy(XY axis) | ±10μm | |

| Scribing accuracy | ±20μm(Image processing accuracy is included.) | ||

| Laser unit | Oscillator | Yb: Fiber laser | |

| Wave length | 1,060nm | ||

| Average output | 18W (Laser head launching part) | ||

| Optical unit | Method | Optical system of scanning (galvanometer type) | |

| Scanning area | Max.□50mm | ||

| Scanning processing speed | Dot processing: Max. 500pore/s, Ditch processing: Max. 500mm/s | ||

| Optical system of observation | Observation as the same axis in the laser light | ||

| Camera view | 6.7×5.0mm | ||

| Lighting installation | Halogen lighting | ||

| Z axis | Automatic focus adjustment of optical unit by work thickness setting | ||

| Image processing | Method | Centering by binary-coded / Pattern matching | |

| Image processing camera | Two (The processing area is made a center, and they are set up right and left.) | ||

| Camera view | 3.2×2.4mm | ||

| Lighting | LED ring lighting(standard: green) | ||

| Control | Control unit | Special controller made of UHT | |

| Operation | Operated by 6.5 inch color liquid crystal touch panel | ||

| Data editing | By interactive software on PC (Separation from main body) | ||

| Network | Transmission of machining data from PC to the machine through LAN, centralized monitoring of the machine (up to 8 units on PC) | ||

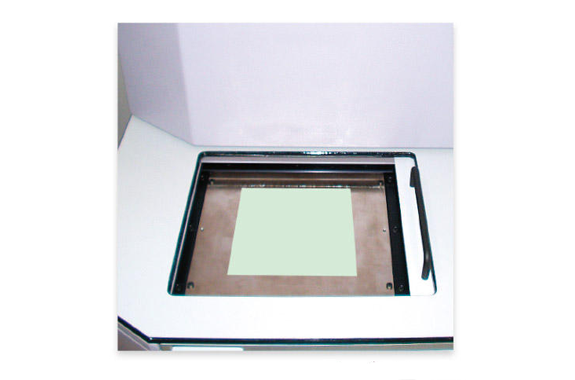

| Dust collector | From the upper side | ||

| Dust proof measures | Air purging type in optical unit, fθ, The protection glass for lens | ||

| Safety device | Safety cover, Key switch, Safety interlock | ||

| Display light | Laser | Green: on excitation, Red: on irradiation | |

| Laser class | Class-1 laser product in compliance with IEC | ||

| Power source | 3φ AC200V ±10% 1.5kVA | ||

| Air source | 0.4~0.7MPa(Clear air) | ||

| Machine | Size | W700×D800×H1400 | |

| Weight | 650Kg | ||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | |

| Humidity | 40~60%(Non-dewing) | ||

Options

- Adjustment table

- Automation module

- Image processing specification

- Management PC software

- Laser output measurement function

- Power box for PC

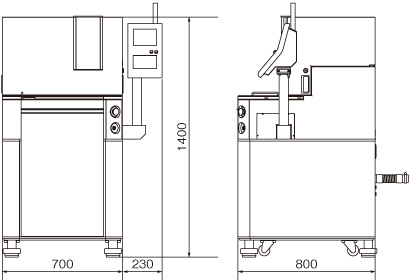

Outline Drawing

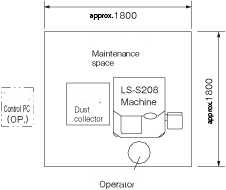

Example of floor layout