- Home

- Products

- UHT CORPORATION MPRO-□in □PL series Linear type Multi Product Punching Machine Selectable set of punch and die + Punch unit

Japan, UHT CORPORATION

UHT CORPORATION MPRO-□in □PL series Linear type Multi Product Punching Machine Selectable set of punch and die + Punch unit

Made in Japan

Manufacturer: UHT CORPORATION

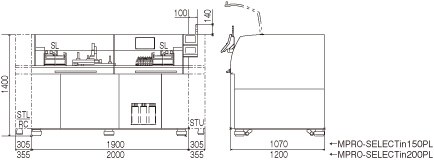

Model: MPRO-SELECTin150PL / MPRO-SELECTin200PL

Features

- Speed-up MPRO Super-high-speed X and Y axes is installed.

Die set unit: Max.900 hole/min × Punch number in metal mold Compared with our conventional model 1.5 times

Punching unit: Max.1500 hole/min (with PUM-25L) 2.5times faster than conventional models

Characteristics

- Punching dies with the highest speed in the worldFlexible productivity

Product punching machine can versatilely meet any scale of production from proto-type work to mass-production.Decrease of initial running cost

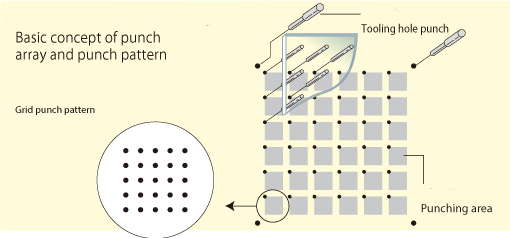

Grid array that can freely conform to punch pattern Combination of die set unit and punching unit realizes flexible punching arrangements and decrease of die cost.

- Basic concept of punch array and punch pattern

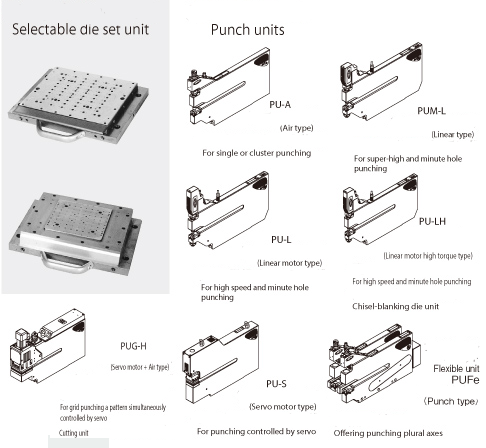

- Selectable die set unit

Selectable die set unit out of various grid arrays. 4 different size of punch is efficiently selectable.(Square punch available)

Standard Specifications

| Model name | MPRO-SELECTin150PL | MPRO-SELECTin200PL | ||

|---|---|---|---|---|

| Work | Material | Ceramic Green Sheet | ||

| Form | Sheet | |||

| Thickness | Max.0.5mm | |||

| Sheet size | Max.□175mm (RC:□200mm) |

Max.□225mm (RC:□250mm) |

||

| Punching area | Max.□150mm | Max.□200mm | ||

| Attachment (How to attach) |

Supply : Sheet : Standard Work holder, Vacuum frame Roll : Vacuum frame |

|||

| Punch | Die set unit | Layout in Max.□200mm 4 different diameters’ punching holes are settable. |

||

| PU unit | 8axes(PU-25 In-serve number) An unit selected by you | |||

| Capability | Punching accuracy | ±10μm(Between 2 points in 1″ punched on UHT’s test film) | ||

| Punching speed | Diesel unit | Die set unit : Max. 900 holes/min + Tooling hole punches (With 1.0mm pitch) |

||

| PU unit | By PUM-25L : Max.1500 hole/min By P U – 2 5 L : Max.1000 hole/min By P U – 2 5 A : Max. 600 hole/min (NC punch with 1mm pitch in Y direction on and standard V/F work holder) |

|||

| Control function | Control | Controller : UHT made MJUC controller | ||

| Operation | 6.5″ color LCD touch panel | |||

| Punch data | Software on PC (independent of the main body) | |||

| Data | 1file(30000 positions) | |||

| Network | Data transfer from P/C to machine through | |||

| Dust collector | Die set unit | External dust collector | ||

| Punching unit | By three reams SJC dust collect method | |||

| Power | 3φ AC200V±10% 3kVA | |||

| Air | 0.4MPa~0.7MPa | |||

| Machine size(Body) | W1900×D1070×H1400mm | W2000×D1200×H1400mm by slide loader: SL |

||

| Machine mass | Approx. 2400kg | |||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | ||

| Humidity | 40~60%(Non-dewing) | |||

Options

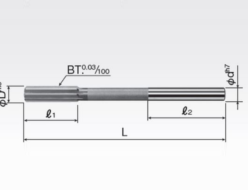

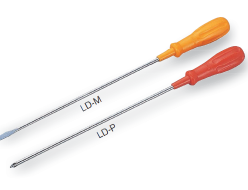

- Punch setter

- Metal mold(Punch, Die)

- Power box

- Selectable die set unit

- Data conversion software from CAD

- PC

- Punch units

- Punch break detecting software

- Booster tank

Outline Drawing