Japan, UHT CORPORATION

UHT CORPORATION MPRO series Multi Product Punching Machine System Line Up

Made in Japan

Manufacturer: UHT CORPORATION

Model: MPRO-PUNCHin150 / MPRO-PUNCHin150P/ MPRO-PUNCHin200 / MPRO-PUNCHin200P

Features

- MPRO System Line Ups can offer high productivity by selecting the best combination from the variety style of machines and loader/unloader modules to satisfy any scale of job depending on the purpose.

- Variety of optional unique and functional automatic loader/unloader module is available.

- MPRO System Line Ups can versatilely meet any scale of production from proto-type work to mass-production.

Characteristics

- High efficiency & productivity for any kinds of punch patterns by best selecting from DIEin, SELECTin or PUNCHin.

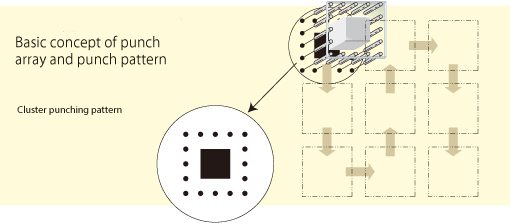

- Cluster punch unit. Square punch available.)

Standard Specifications Punch in

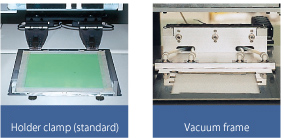

Model name MPRO-PUNCHin150 MPRO-PUNCHin200 MPRO-PUNCHin150P MPRO-PUNCHin200P Work Material Ceramic Green Sheet Form Sheet Thickness Max. 0.5mm Size Roll width Max.200mm Max.250mm Sheet Max.□200mm Max.□250mm Punching area Max.□150mm Max.□200mm Attachment(How to attach) Supply : Sheet : V/F Work holder, Vacuum frame

Roll : Vacuum framePunch Die set unit Layout in Max.

□70mmLayout in Max.

□120mm4 sets of tooling punch(+O.P) PU unit 6axes(PU-25 In-serve number) An unit selected by you Capability Punching accuracy ±10μm(Between 2 points in 1″ punched on UHT’s test film) Resolution X-axis Y-axis:1μm Punching speed Die set unit Die set unit : Max. 600 holes/min + Tooling hole punches(With 1.0mm pitch) PU unit Max.600 hole/min NC punch on PU-25 with 1mm pitch in Y direction Feed speed Max.30m/min(Simultaneous 2-axis control) Data 1file(30000 positions) Control function Control Controller : UHT made MJUC controller Operation 6.5″ color LCD touch panel Punch data By interactive software on outstanding P/C Network Data transfer from P/C to machine through Dust collector Via Punch : External dust collector

Tooling punch : EjectorPU unit : Ejector Power 3φ AC200V±10% 2kVA Air 0.4MPa~0.7MPa Machine size With loader module(Both sides) W1440×D1200×H1600mm W1665×D1280×H1600mm W1990×D1290×H1600mm W2315×D1470×H1600mm Machine mass Approx.1100kg Approx.1500kg Approx.1350kg Approx.1750kg Working condition Temperature 10~35℃(22±2℃ recommended) Humidity 40~60%(Non-dewing) Standard Specifications DIE in

Model name MPRO-DIEin150 MPRO-DIEin200 MPRO-DIEin150P MPRO-DIEin200P Work Material Ceramic Green Sheet Form Sheet Thickness Max. 0.5mm Size Roll width Min.150~Max.200mm Min.200~Max.250mm Sheet Min.□150~Max.□200mm Min.□200~Max.□250mm Punching area Max.□150mm Max.□200mm Tooling punch Max.□170mm Max.□220mm Attachment(How to attach) Supply : Sheet : V/F Work holder, Vacuum frame

Roll : Vacuum framePunch Die set unit Layout in Max.□150mm Layout in Max.□200mm 2 sets of tooling punch (+O.P) PU unit 6axes(PU-25 In-serve number) An unit selected by you Capability Punching accuracy ±10μm(Between 2 points in 1″ punched on UHT’s test film) Resolution X-axis Y-axis:1μm Punching speed Die set unit Die set unit : Max. 600 holes/min + Tooling hole punches (With 1.0mm pitch) PU unit Max.600 hole/min NC punch on PU-25 with 1mm pitch in Y direction Feed speed Max.30m/min(Simultaneous 2-axis control) Data 1file(30000 positions) Control function Control Controller : UHT made MJUC controller Operation 6.5″ color LCD touch panel Punch data By interactive software on outstanding P/C Network Data transfer from P/C to machine through Dust collector Via Punch : External dust collector

Tooling punch : EjectorPU unit : Ejector Power 3φ AC200V±10% 2kVA Air 0.4MPa~0.7MPa Machine size With loader module(Both sides) W1440×D1200×H1600mm W1665×D1280×H1600mm W1990×D1200×H1600mm W2315×D1470×H1600mm Machine mass Approx. 900kg Approx. 1100kg Approx. 1350kg Approx. 1600kg Working condition Temperature 10~35℃(22±2℃ recommended) Humidity 40~60%(Non-dewing) Standard Specifications Select in

Model name MPRO-SELECTin150 MPRO-SELECTin150P MPRO-SELECTin200P Work Material Ceramic Green Sheet Form Sheet Thickness Max. 0.5mm Size Roll width Max.200mm Max.250mm Sheet Max.□200mm Max.□250mm Punching area Max.□150mm Max.□200mm Tooling punch Max.□200mm Attachment(How to attach) Supply : Sheet : V/ FWork holder, Vacuum frame

Roll : Vacuum framePunch Die set unit Layout in Max.□150mm Layout in Max.□200mm 4 different diameters’ punching holes are settable. 4 sets of tooling punch (+O.P) PU unit 6axes(PU-25 In-serve number) An unit selected by you Capability Punching accuracy ±10μm (Between 2 points in 1″ punched on UHT’s test film) Resolution X-axis Y-axis :1μm Punching speed Die set unit Die set unit : Max. 600 holes/min + Tooling hole punches(With 1.0mm pitch) PU unit Max.600 hole/min NC punch on PU-25 with 1mm pitch in Y direction Feed speed Max.30m/min(Simultaneous 2-axis control) Data 1file(30000 positions) Control function Control Controller : UHT made MJUC controller Operation 6.5″ color LCD touch panel Punch data By interactive software on outstanding P/C Network Data transfer from P/C to machine through Dust collector Via Punch : External dust collector

Tooling punch : EjectorPU unit : Ejector Power 3φ AC200V±10% 2kVA Air 0.4MPa~0.7MPa Machine size With loader module(Both sides) W1665×D1280×H1600mm W1990×D1200×H1600mm W2315×D1420×H1600mm Machine mass Approx.1100kg Approx.1350kg Approx.1600kg Working condition Temperature 10~35℃(22±2℃ recommended) Humidity 40~60%(Non-dewing) Options

Auto loader/unloader(indispensable)

〇Module(Externally equipped)

※P type machine can have line type loader module only.

Die set unit

・DIEin

・SELECTin

・PUNCHin

Type of clamp

Standard V/F or vacuum frame

θ finger

Available for either V/F or vacuum frame

Image processor

Work offset by binary image to detect the center of gravity of target mark.

CAD interface

Data conversion software from CAD data direct to punching data.Broken punch detector

Pause the machine running by detecting the punch breakage using image processorBush setter

For insertion/removal of die bush

Die setting machine

DIEin/SELECTin/PUNCHin

For die set tooling setting and test punching

Lift car

For tooling exchange

Related Products

-

Organo D-4 FU-M2 Commercial Water Purifier

-

SAKUSAKU SG-44M-D Carbide Rotary Burr Three Pointed End Shape

-

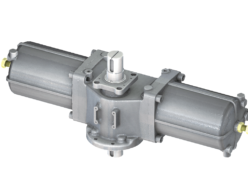

KONAN TW3 Rotary Actuaion Double-Acting Type

-

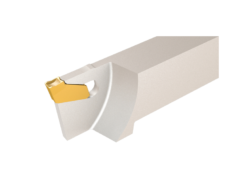

SAKUSAKU SDHL20120203 Holder For Grooving And Parting Off

-

Arimitsu SDB-10A2/ SDB-15A2 Knapsack Type Motor-powered Sprayers (Lithium battery)

-

Nippon TA Hand-Finished Surface Roughness Standard Plate