Japan, UHT CORPORATION

UHT Corporation NCD-8060E Series Drilling Machine For Prepreg And Copper Foil

Made in Japan

Manufacturer: UHT CORPORATION

Model: NCD-8060E Series

Changed from air motor drive to electric spindles High-accuracy, high-speed and quiet drilling

Clean drilling of packaged materials Up to 25 mm thickness.

Characteristics

Optimum drilling with high-torque and high-power spindles

High-speed electric spindles with stable RPM enable optimum step feed and RPM control appropriate for material types

High-accuracy and high-speed drilling

Newly designed rigid structure

No workpiece deterioration or contamination

Clean drilling on up to 25-mm thickness workpieces

Inherited features:

Coolant air from special cutter tips

Workpiece clamping method

Drilling from below to prevent slug pullingEasy cutter exchange from the table surface.

Standard Specifications

| Model | NCD-8060E | |||

|---|---|---|---|---|

| Workpiece | Material | Inner materials and copper foil for multi-layer boards | ||

| Drilling area | Max. 820×620㎜ | |||

| Thickness | 25㎜ (incl. bottom & retainer plates) | |||

| Spindle | Drive | UHT’s original electric spindle | ||

| Capacity | Rotation speed | 1000~5000rpm | ||

| Stopping accuracy | ±30μm | |||

| Hole dia. | 6~10㎜ | |||

| Travel speed | Pulse resolution | Stroke | ||

| X | 30m/min | 1μm | 820㎜ | |

| Y | 30m/min | 1μm | 620㎜ | |

| Z | 0.05~50㎜/sec | 1μm | 80㎜ | |

| Z-axis step | 1~999 steps | |||

| Axis drive | Ball screws | |||

| Data | Storage | Memory card | ||

| Capacity | 100 channels (28 positions/channel) | |||

| Method | Numeric input from the touch panel | |||

| Controller | UHT’s original controller | |||

| Operation | Via touch panel | |||

| Safety devices | Photoelectric sensors, tape switches, mat switches | |||

| Utility | Power | 3-phase, 200V AC ±10%, 20A | ||

| Air | 0.4~0.7 MPa (clean air) | |||

| Dust collector | Static pressure: 20kPa, Airflow: 3.5m3/min | |||

| Refrigerated air dryer (optional) | 75W, 200V AC | |||

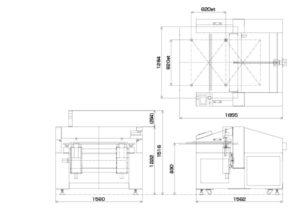

| Dimensions | W1560×D1855×H1516㎜ | |||

| Weight | 700kg | |||

| Environment | Temperature | 10~35°C (22 ±2°C recommended) | ||

| Humidity | 40~60% (non-condensing) | |||

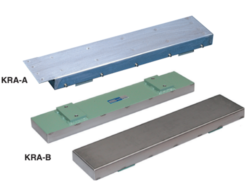

| Options | Cutter, table drilling kit, Refrigerated air dryer, Dust collector, PC connection | |||

Outline Drawing