Japan, UHT CORPORATION

UHT Corporation PZ-ROBO N2 Series Punching Machine For Flexible Substrates

Made in Japan

Manufacturer: UHT CORPORATION

Model: PZ-ROBO N2, PZ-ROBO N2gPZ-ROBO N2 2000, PZ-ROBO N2g 2000

Applicable to large sheets of work

High speed, high accuracy

130 holes/min,±20μm

Simple shape designed in emphasis on the ease of work.

Teaching mechanism makes positioning operations much easier.

Characteristics

A maximum of 600x500mm, large-sized,

The flexible substrate can be punchedAchieved highly accurate processing

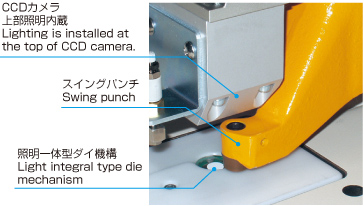

・A three-dimensional cam with results ensures quiet and smooth punching.

・Top lighting(three different colours) and lower lighting are available to deal with clear picture processing of various colours of work and/or patterns.

Installing of the teaching mechanism

Positions to punch can be taught using a teaching dial instead of entering the coordinates. The storage capacity of the position data is 100 channels, each equivalent to 1000 positions. The position data can be stored in the memory card.

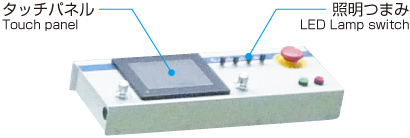

Easy-to-use interface

Touch panel and operation switch provides a comfortable working environment for operators.

Standard Specifications

| Model name | PZ-ROBO N2 | PZ-ROBO N2g | PZ-ROBO N2 2000 | PZ-ROBO N2g 2000 | |

|---|---|---|---|---|---|

| Work | Applicable materials | Flexible substrates laminated flexible substrates and nameplates | |||

| Max Work thickness | Max.1.0mm (depending on the punch diameter & material) | ||||

| Max Working area | Max.X600×Y500mm | ||||

| Die | Punched hole diameter | φ0.6~6.0mm(Optional Max.φ6.49) | |||

| Capability | Punching Accuracy | ±20μm | |||

| Punching speed | 130holes/min.(At image processing during movement in 20mm pitches. Varies according to the punching and material conditions) | ||||

| Punching power | Max.1100N | Max.2000N | |||

| Image processing | Display | 5.5-inch TFT LCD | |||

| Target Mark Size | φ0.6~3.0mm | ||||

| Searching Mechanism | Centring by binary-coded | ||||

| Pattern matting | Pattern matting | ||||

| Range of View | Standard View 5.0×4.0mm Digitized View 4.5×3.5mm | ||||

| Illumination | LED, 3 colours from the upper side, 1 colour from underneath | ||||

| Control | Control unit | the special controller made of UHT | |||

| Operation | Touch panel and an operation switch | ||||

| Programming method | Teaching playback method | ||||

| Programming capacity | 100 channels(1000 holes/channel)Internal memory,Memory card | ||||

| Storage | P/C(OP.) | ||||

| Editing feature | Delete, Copy, Modify, Offset of work origin, Repeating | ||||

| Power source | 3φ AC200V ±10% 1.0kVA | ||||

| Air Pressure source | 0.5MPa(Clean air) | ||||

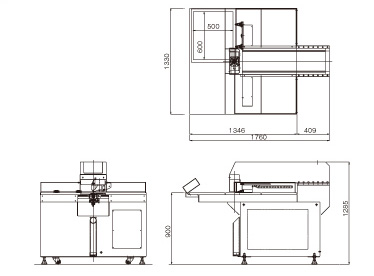

| Dimension | W1330×D1760×H1285mm | ||||

| Weight | Approx.500Kg | ||||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | |||

| Humidity | 40~60%(Non-bedewing) | ||||

Options

PC for data storage

Metal mold

Outline Drawing

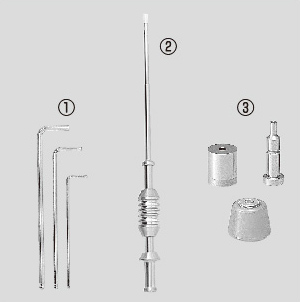

Accessories

| Name | Amount |

|---|---|

| ①Hexagonal Wrench Set (3types) | 1 |

| ②Punch・Die Replace Tool | 1 |

| ③Punch、Die、 Stripper | each 1 |

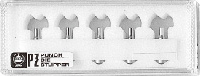

Optional

- Punches(one set of five punches)

- Dies(one set of five dies)

- Strippers(one set of five strippers)