Drilling and Cutting, Japan, Unika

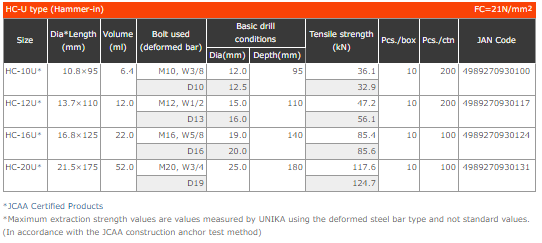

UNIKA HC-U Type (Hammer-in) Resin A

Manufacturer: UNIKA

Model: HC-U type (Hammer-in)

- ■Hammering only to install. OK for different sized bolts and rebar.

- ■Glass tube shape designed for fewer times to hammer.

- ■Good holding of glass and vinyl ester resin with high alkali resistance. Long shelf life before use.

- 1.Drill parent material.

- 2.3.Cleaning in the hole. Remove debris inside hole cleanly using brush or blower.

- 4.Insert capsule in direction of arrow.

- 5.Screw in bolt. Hammer in to bottom of hole.

- 6.After inserting the item to be fixed, rotate it 2-3 times. Then, do not move it under the end of the curing time.

■Uses

Foundation work using steel reinforcers etc., highway construction, installation work for vibrating machines.

■Construction Drawing

■Bolt Shape Used

Make sure to use one with an irregular surface for the edge of the anchor bar by flush cut. Use the hex head set screw or deformed steel bar.

■Hardening Time Standard

| Temperature(°C) | -5 | 5 | 20 | 30 |

|---|---|---|---|---|

| Initial Hardening Time (min.) | 300 | 60 | 30 | 15 |

(Do not move the anchor bar during the hardening time.)

- The drilling diameter and depth must be according to the specification.

- Clean the hole drilled with a metal brush and blowing equipment.

- Be sure to insert the capsule in the direction of the arrow mark. Inserting in the wrong direction reduces the adhesiveness.

- Put a mark on the anchor bolt to indicate the inserting depth.

- Put on the attached cap to the anchor bolt before the installation.

- Be sure to wear safety protective equipment such as a facemask, eye protection glasses, and safety gloves during use.

- Use hammers of approximately 1.5kg in weight.

- For overall screw bolts, hammer in those bolts with nuts attached on the hammered parts or use plastic hammers to protect the bolt heads.

- Hammer in the capsule with appropriate impact forces to prevent the materials inside the capsule from splashing out.

- Hammer in the bolts or steel bars of different shapes until the position marked.

- Do not move the bolts or the steel bars of different shapes during the specified period for solidification after hammering in.

- Do not drill with water.

- For double bolt installation, hammer in the both bolts by machine.