Drilling And Cutting, Japan, Unika

UNIKA Meta-core TR T.C.T Hole Saw Without Collar

Manufacturer: UNIKA

Model: Ultra-hard hole saw – Meta-core TR [Without collar] (MCTR-TN type)/ Center drill (cobalt)/ Meta-core TR Without collar (Tool Box Set)

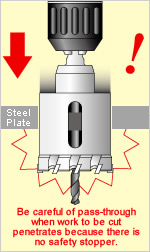

■Without a stopper (collar), added depth of cut is possible.

■3-ply cutters reduce tip cracks even with hard use.

■The 35mm effective depth enables drilling materials such as thick steel plates, curved surfaces of metal pipes having heavy large wall thickness etc.

◆Effective length: 35mm(Full depth: 37 mm)

◆Matching Drill: Electric drill/drilling machine/Percussion drill(rotating mode)

◇Compatible with pipes and stainless steel

USES

Metal siding• Stainless steel panels (10mm or less)• Pipe materials• Aluminum panels (5mm or less)• FRP panels• Plywood• Plasterboard

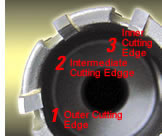

■3-Ply Cutters

Cutting the shavings to one-third with respect to the cutting width using 3-ply cutters (outer, inner and intermediate cutting blades) has dramatically decreased cracks on the tip corner. This also includes inside cutting edges so debris can be discharged smoothly.

-

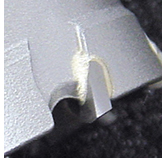

■Drilling swarf discharge groove

Drilling swarf is efficiently discharged through the discharge grooves that are also compatible with thick steel plates. Clogging of drilling swarf between the work material and cutting edge makes drilling impossible, which leads to tips cracking and chipping.

-

■Slavings Escape Hole

An escape hole, which is convenient for shavings removal, is equipped with hole saws of all diameters.

After removing the main unit from the motor, insert the metal rod that fits through the hole, etc., into the shavings escape hole and push out debris.

After removing the main unit from the motor, insert the metal rod that fits through the hole, etc., into the shavings escape hole and push out debris.

-

■Thinning center drill

In drilling with a hole saw, a center drill starts drilling initially. The center drill serves as a rotation center shaft of the hole saw by making the center drill penetrate, and the cutting edge can stably cut work to be cut.

■Appropriate Rotation Speed

- ■Use the drill at a rotation speed appropriate for the drilling work material and diameter.

- ■When drilling a thick plate with a thickness of 5 mm or more or for continuous cutting, select a lower rotation speed.

■Peripheral Speed

| Stainless Steel | Common Steel | Aluminum |

|---|---|---|

| 25-35 m/min | 40-60 m/min | 60-100 m/min |

- Securely chuck the three-surface section of the shank to prevent swinging or falling.

- Do not reduce the rotation speed excessively during drilling. Jamming or tip cracking may result.

- Do not hit the cutting edges of the tungsten carbide/ultra-hard tip against any hard object or allow strong contact with the work material that may occur when the center drill passes through. The tip will crack.

- In the case of continuous drilling using a drilling machine, watch out for overheating of the cutting edge and use cutting fluid or stop drilling to cool the cutting edge.

SPECIFICATION

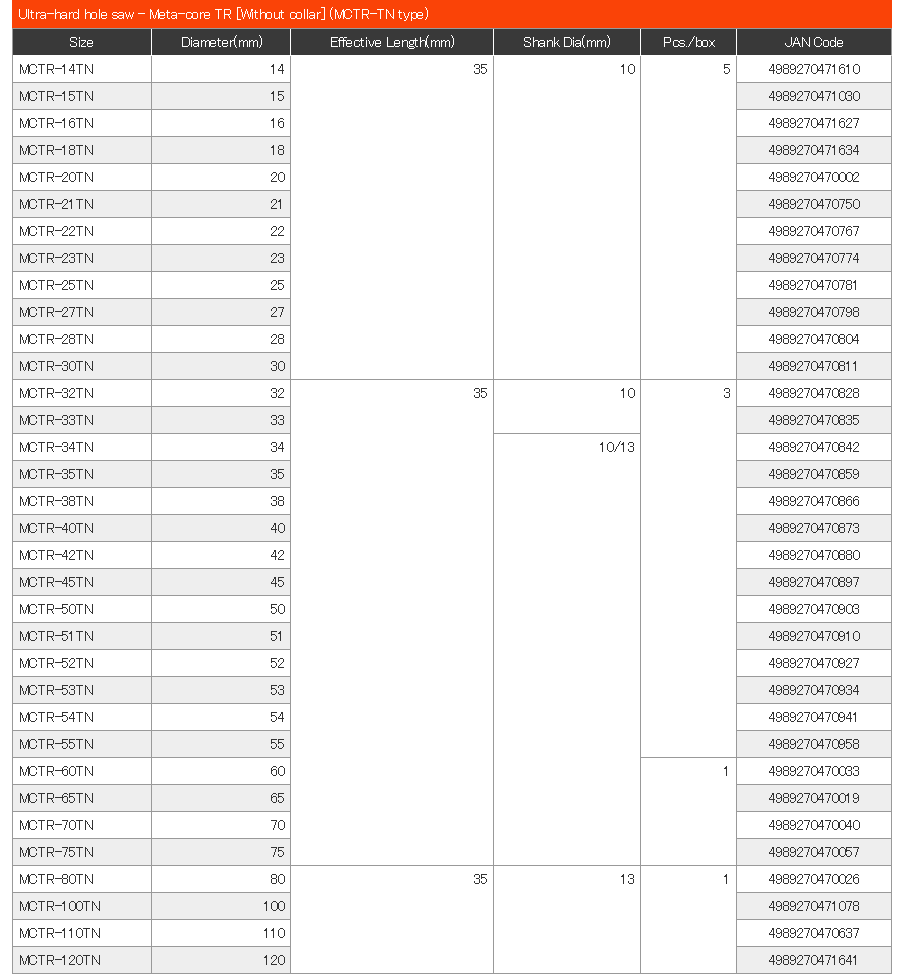

Ultra-hard hole saw – Meta-core TR [Without collar] (MCTR-TN type)

| Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) | Size | Diameter(mm) |

| MCTR-14TN | 14 | MCTR-27TN | 27 | MCTR-42TN | 42 | MCTR-65TN | 65 |

| MCTR-15TN | 15 | MCTR-28TN | 28 | MCTR-45TN | 45 | MCTR-70TN | 70 |

| MCTR-16TN | 16 | MCTR-30TN | 30 | MCTR-50TN | 50 | MCTR-75TN | 75 |

| MCTR-18TN | 18 | MCTR-32TN | 32 | MCTR-51TN | 51 | MCTR-80TN | 80 |

| MCTR-20TN | 20 | MCTR-33TN | 33 | MCTR-52TN | 52 | MCTR-100TN | 100 |

| MCTR-21TN | 21 | MCTR-34TN | 34 | MCTR-53TN | 53 | MCTR-110TN | 110 |

| MCTR-22TN | 22 | MCTR-35TN | 35 | MCTR-54TN | 54 | MCTR-120TN | 120 |

| MCTR-23TN | 23 | MCTR-38TN | 38 | MCTR-55TN | 55 | ||

| MCTR-25TN | 25 | MCTR-40TN | 40 | MCTR-60TN | 60 |

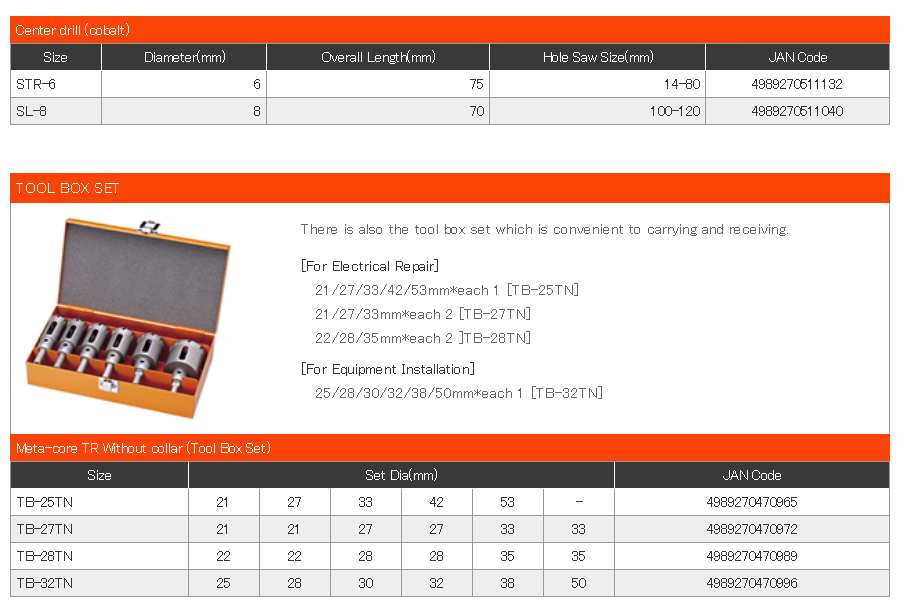

Center drill (cobalt) Meta-core TR Without collar (Tool Box Set)

| Size | Diameter(mm) | Size | Set Dia(mm) | |

| STR-6 | 6 | TB-25TN | 21 | |

| SL-8 | 8 | TB-27TN | 21 | |

| TB-28TN | 22 | |||

| TB-32TN | 25 |