Drilling and Cutting, Japan, Unika

UNIKA TR Type Ceramic Tile Drill Bit

- Manufacturer: UNIKA

- Model: TR type

- ■Ideal for drilling approximately 10 to 15 ceramic tiles.

- ■Uses a special ultra-hard tip to maintain drilling performance. Drills efficiently through even difficult materials.

- ■Even more outstanding cutting efficiency and durability is demonstrated if cooled using water when drilling.

◆Matching drill: Electric drill/Percussion drill(rotating mode)

■Asymmetric cutting edge shape

Asymmetrical grinding the ultra-hard tip of the cutting edge reduces cutting resistance, enabling work material drilling with low torque.

■Appropriate rotation speed of electric drill used

![]()

■Chuck Size

Drill bit of all sizes attachable to the 10-mm chuck.

■Comparison of hole drilling count when water is used and not used

*The hole drilling count varies depending on the tile type.

<Dia>

3.0-6.5mm

(32*10*145)

<Dia>

7.0-8.5mm

(32*12*176)

<Dia>

9.0-11.0mm

(37*14*197)

*( ) The number inside is package size. W*D*H(mm). As for size there is the error of ±2mm depending upon the package.

- For TR Type drill, use rotation mode only. Never use the vibration mode.

- Be sure to turn off the main switch of the electrical drill and disconnect the power supply plug from the socket before attaching and detaching the drill bit.

- Attach the drill bit by pushing in until it stops at the end of the chucking part of the drill, and clamp the drill bit tightly so it will not loosen or coming off.

- Wear eye protection glasses.

- Drill holes vertically against the drilled material surface.

- Operate the drill with water being poured onto the tip of the drill bit used for cooling.

- Read the instruction manual for the electrical drill used carefully before use and always observe those instructions to ensure safe and correct operation.

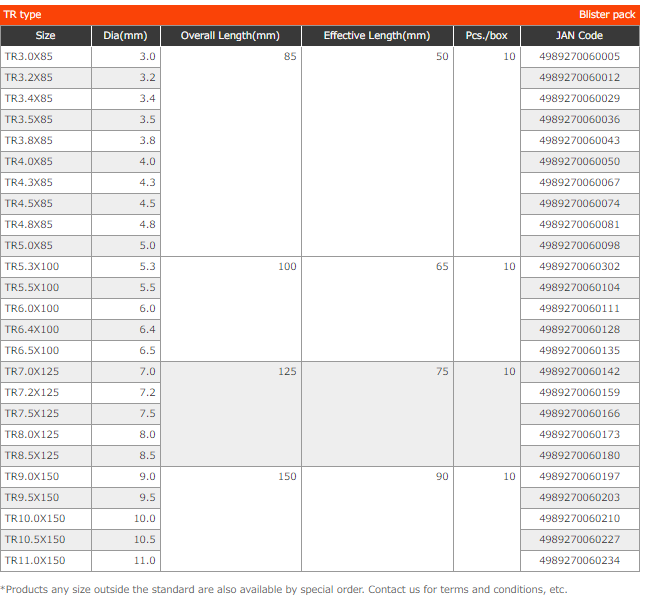

- SPECIFICATIONS

- TR type

| Size | Dia(mm) |

| TR3.0X85 | 3 |

| TR3.2X85 | 3.2 |

| TR3.4X85 | 3.4 |

| TR3.5X85 | 3.5 |

| TR3.8X85 | 3.8 |

| TR4.0X85 | 4 |

| TR4.3X85 | 4.3 |

| TR4.5X85 | 4.5 |

| TR4.8X85 | 4.8 |

| TR5.0X85 | 5 |

| TR5.3X100 | 5.3 |

| TR5.5X100 | 5.5 |

| TR6.0X100 | 6 |

| TR6.4X100 | 6.4 |

| TR6.5X100 | 6.5 |

| TR7.0X125 | 7 |

| TR7.2X125 | 7.2 |

| TR7.5X125 | 7.5 |

| TR8.0X125 | 8 |

| TR8.5X125 | 8.5 |

| TR9.0X150 | 9 |

| TR9.5X150 | 9.5 |

| TR10.0X150 | 10 |

| TR10.5X150 | 10.5 |

| TR11.0X150 | 11 |

Related Products

-

Fukudaco Modular Clamping System

-

Japan Life FCI Insert For Concrete Works (For Suspended Scaffolding)

-

Chiyoda Tsusho 4/6/8/10/12R-OOY FUJI Y CONNECTOR [RESIN BODY]

-

TONE RH31F Ratchet Handle, Flex Round Head

-

Chiyoda Seiki EX-20mkII-G3 Pressure Regulator For Laser Gas Cylinder (4 kinds of mixed gas He, N2, CO2, CO)

-

Chino CP350/CP370 Series Digital Indicating Controller