| industry | automobile industry |

|---|---|

| Work name | Transmission (torque converter) |

| Processing details | Others (stud bolt processing) |

| Machine configuration | 2 heads 1 jig indexing |

| Transport format | Gantry transport, AWC |

| specification | High-speed U-axis NC unit |

| Made date | 2004.08 |

Yamashina Seiki

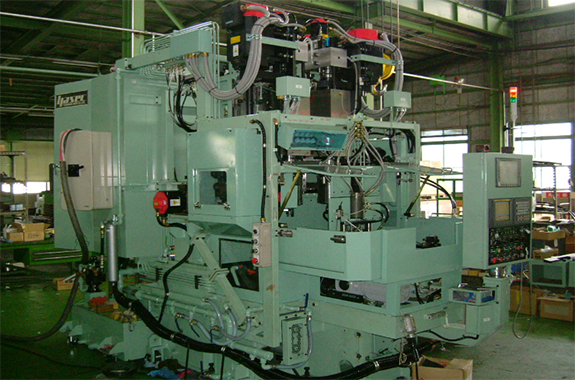

Yamashina Seiki 2-Spindle Vertical Machining Center With U-axis Control Function

Product Made In Japan

Manufacture: Yamashina Seiki

In general, machining centers mainly perform surface processing by milling and hole processing by drilling, tapping, boring, etc., but here we will use a spindle with a U-axis function to weld the center boss and stud bolt material of torque converter parts. This article describes a machining center that efficiently performs external diameter machining.

1. High-efficiency, high-precision machining using a high-speed U-axis control spindle (maximum spindle rotation speed 4000 rpm)

2. ) has flexibility.

3. The installation and removal of workpieces, clamping and unclamping of jigs are fully automatic, and the system is also carried in and out by a loader from outside the processing area.

4. It has a compact configuration that combines the functions of two machines into one without waste.

(Left and right spindle head units operate independently for U, Y, and Z)

Related Products

-

Yamashina Seiki SP Type High Pressure Lubricator

-

Yamashina Seiki Column Traverse Type CNC Pipe Phaser

-

Yamashina Seiki FlexLink Conveyor

-

Yamashina Seiki Boring Machine For Finishing Holes on Both Ends of Connecting Rods

-

Yamashina Seiki Automatic Fuel Oil Switching Device

-

Yamashina Seiki Vertical Axle Housing Boring and Facing Machine by NC Facing Head