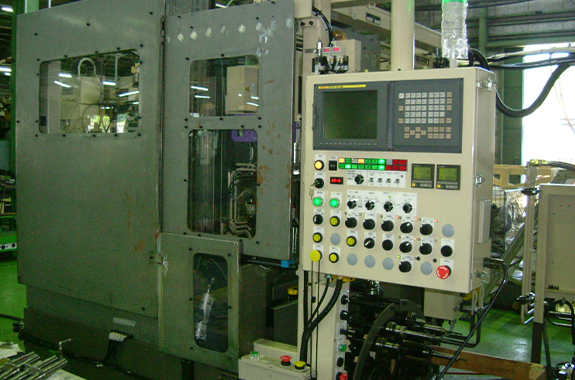

| industry | Industrial machinery industry, construction/steel industry |

|---|---|

| Work name | Others (input shaft) |

| Processing details | Drilling, tapping, reaming (deep hole drilling) |

| Machine configuration | Single CNC machine |

| Transport format | Manual transport (automatic attachment/detachment) |

| specification | MQL, 5 axis CNC |

| Made date | 2004.06 |

Yamashina Seiki

Yamashina Seiki A Compact Vertical Machining Center Focused on Chip Processing and MQL

Product Made In Japan

Manufacture: Yamashina Seiki

・Since the upward spindle unit

jig is above the spindle, there is no accumulation of chips, and the chips do not go against gravity, so the life of the cutting tool is significantly increased due to the spindle, which has fast chip discharge, and has measures against chip intrusion. Machining holes Since chips do not damage the hole, the hole is clean. – 5-axis control, B-axis and A-axis are installed in X, Y, and Z, so machining can be done from any direction. – Complete MQL (Minimum Quantity Lubrication) Achieves machining – Powerful for machining oil holes on crankshafts, camshafts, input shafts, spools, etc., in one setup (all-in-one) for machining holes perpendicular to the shaft, holes on end faces, holes at inclined angles, and notch milling. will demonstrate.

jig is above the spindle, there is no accumulation of chips, and the chips do not go against gravity, so the life of the cutting tool is significantly increased due to the spindle, which has fast chip discharge, and has measures against chip intrusion. Machining holes Since chips do not damage the hole, the hole is clean. – 5-axis control, B-axis and A-axis are installed in X, Y, and Z, so machining can be done from any direction. – Complete MQL (Minimum Quantity Lubrication) Achieves machining – Powerful for machining oil holes on crankshafts, camshafts, input shafts, spools, etc., in one setup (all-in-one) for machining holes perpendicular to the shaft, holes on end faces, holes at inclined angles, and notch milling. will demonstrate.

Related Products

-

Yamashina Seiki Horizontal Type Column Movement Type 2 Spindle Machining Center Connecting Rod Bolt Hole Processing Machine

-

Yamashina Seiki Oil Cooler

-

Yamashina Seiki Tank Cleaning Heater

-

Yamashina Seiki GS Type Small Grease Pump

-

Yamashina Seiki Transfer Machine For in-line 4 Cylinder Block Processing

-

Yamashina Seiki Dedicated Machine for Processing Control Valves and Construction Machinery