| industry | Industrial machinery |

|---|---|

| Work name | Engine (conrod) |

| Processing details | Drilling (oil hole gun drill) |

| Machine configuration | Single-use machine |

| Transport format | pallet feed |

| specification | Gundrill deep hole drilling |

| Made date | 2008.02 |

- Home

- Products

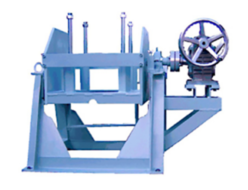

- Yamashina Seiki Dedicated Gun Drill Machine for Large Connecting Rods Oil Hole Machining

Yamashina Seiki

Yamashina Seiki Dedicated Gun Drill Machine for Large Connecting Rods Oil Hole Machining

Manufacture: Yamashina Seiki

Overview

This machine, manufactured for processing diesel engine connecting rods, has two workpiece jig pallets placed on the front side and has a design structure that efficiently supports the production of a wide variety of workpieces in small quantities. The cutting oil device with a temperature controller optimally controls the temperature of the cutting oil and considers machining conditions. A cutting oil separator is installed at the exit of the chip conveyor to minimize the amount of cutting oil that adheres to chips.

Features

Gun drill unit specifications

– Spindle motor / AC3.7kw – Spindle rotation speed / 1200-2800rpm – Lubrication / oil mist

– Feed stroke / 1350mm – Rapid feed speed / 6m/min – Workpiece material / SFCM80

– Hardness / HB243-294 – Machining hole Diameter: Φ8~Φ16 ・Cutting speed: 60~70m/min

・Feed rate: 0.04~0.06mm/rev.

Related Products

-

Yamashina Seiki FTL for Valve Housing Machining using Horizontal Opposed Machining Cell, Vertical Machining Cells

-

Yamashina Seiki Horizontal Type Column Traverse Swivel 5-axis Machining Center Large Crankshaft Oil Hole Drilling Machine With 2 Head Gun Drill Unit

-

Yamashina Seiki GS Type Small Grease Pump

-

Yamashina Seiki Rotating Workbench

-

Yamashina Seiki Crankshaft Double End Face Processing Machine For Medium-sized Diesel Engines

-

Yamashina Seiki Transfer Machine For Crankcase Processing