Yamashina Seiki

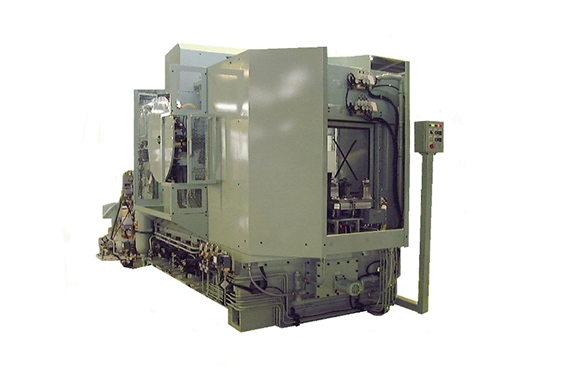

Yamashina Seiki High-speed NC Facing (U-axis Center)

Product Made In Japan

Manufacture: Yamashina Seiki

Model: NC

Overview

NC facing is a method that uses a Z-axis for the spindle’s center and a U-axis for radial movement, both driven by an NC.

Our previous NC facing units medium-speed (1500 rpm or less), high rigidity, capable of heavy cutting, and highly accurate for machining steel.

The newly developed unit is a high-speed, high-precision, light-cutting unit.

The Main Points

1. High-speed spindle rotation — 5000 rpm (compatible with all strokes)

2. Maximum U-axis stroke — 26mm (radius value)

3. Comes with an ATC mechanism.

F = αWrn2 (F: centrifugal force, α: constant, W: weight, r: center of gravity radius offset, n: rotation speed)

At 5000 rpm, with a moving object weight of 1 kg and a center of gravity offset of 13 mm, the centrifugal force reaches 3500 N, causing vibrations and potential damage to the drive system.

This mechanism uses an eccentric shaft configuration to prevent the center of gravity from shifting, eliminating external centrifugal force on the head and drive system. The design is compact and lightweight.

The double eccentric shaft structure maintains a constant cutter rake angle by mechanically reversing and synchronizing it, allowing smooth facing processing over the entire stroke.

The unit machines multiple diameters with one tool and supports ATC for diverse tools, resolving all issues from conventional machining. Our company continues developing the system to meet higher speed demands.

| industry | Automotive industry, electrical industry, general |

|---|---|

| Work name | bearings etc. |

| Processing details | Drilling, facing, tapered hole, tapered thread cutting |

| Machine configuration | – |

| Transport format | – |

| specification | High-speed U-axis machining |

| Made date | – |

Related Products

-

Yamashina Seiki Dedicated Rear Axle Case Processing Machine

-

Yamashina Seiki Condenser

-

Yamashina Seiki MAN B-W Type Cylinder Lubricator

-

Yamashina Seiki A Compact Vertical Machining Center Focused on Chip Processing and MQL

-

Yamashina Seiki Opposed Hollow Facing Machine For Motor Frame Processing

-

Yamashina Seiki Cardboard Cutting and Contents Automatic Extraction Device