| industry | ship |

|---|---|

| Work name | Stern parts (marine propeller) |

| Processing details | Composite machining (propeller boss machining) |

| Machine configuration | Single NC dedicated machine |

| Transport format | manual |

| specification | Manual replacement of boring, facing, drill, tap, and milling heads |

| Made date | 2008.10 |

- Home

- Products

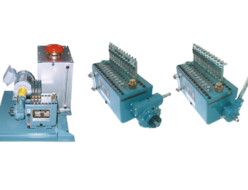

- Yamashina Seiki Horizontal NC Compound Processing Machine for Large Ship Propeller Boss Hole Machining

Yamashina Seiki

Yamashina Seiki Horizontal NC Compound Processing Machine for Large Ship Propeller Boss Hole Machining

Product Made In Japan

Manufacture: Yamashina Seiki

This machine is a multi-tasking machine that continuously performs rough machining to finishing machining in the same process using various machining heads equipped with propeller boss holes, making it dramatically more efficient than conventional horizontal boring machines. It is possible to increase production efficiency and improve processing accuracy. High-precision finishing is especially possible on tapered hole machining surfaces.

Related Products

-

Yamashina Seiki BT-50 – Horizontal Column Traverse Type Machining Cell for Truck and Bus Front Axle End Machining

-

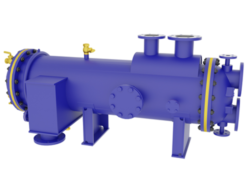

Yamashina Seiki Drain Cooler

-

Yamashina Seiki Condenser

-

Yamashina Seiki ML Type Element Type Lubricator

-

Yamashina Seiki Cylinder Liner Material High Speed Cutting System

-

Yamashina Seiki Dedicated Gun Drill Machine For Drilling Oil Holes