Yamashina Seiki

Yamashina Seiki YS Type High-Speed Centrifugal Barrel Polishing Machine

Manufacture: Yamashina Seiki

Model: YS Type

Improved deburring, chamfering, and surface roughness, stable quality that anyone can use

What is centrifugal barrel polishing?

The four tanks inside the machine undergo high-speed rotation that combines revolution and rotation, polishing the workpieces in the tanks in a short time. Furthermore, the polishing efficiency is improved by adding figure-of-eight flow generated in the tank. The four tanks are removable, making it suitable for high-mix, low-frequency, and small-lot products.

Use/purpose

[Polishing] Deburring and chamfering after forming such as machining and pressing, scaling of heat-treated products and forged products, rough polishing of surfaces [

Finishing] Surface finishing after plating and before painting, gloss finishing, improving surface roughness

Point 1

[Improved safety]

Prevent any unexpected situations from occurring.

Two-handed push button for manual rotation operation.

Point 2

[Time reduction]

Ideal for high-mix, low-frequency, and small-lot products.

Equipped with 4 removable 5L tanks that are easy to use.

The diagonally installed tank creates a figure-of-eight flow for even and efficient polishing.

Point 3

[Improved polishing efficiency]

The timing belt suppresses rotation loss and maximizes polishing efficiency.

Point 4

[Improved work efficiency]

Improved darkness at hand, equipped with LED light.

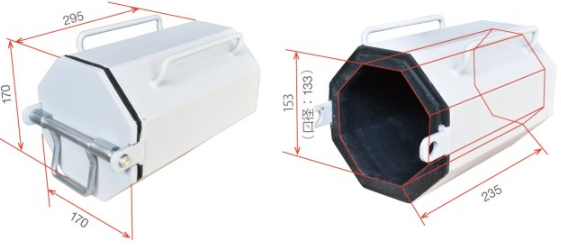

Body Size

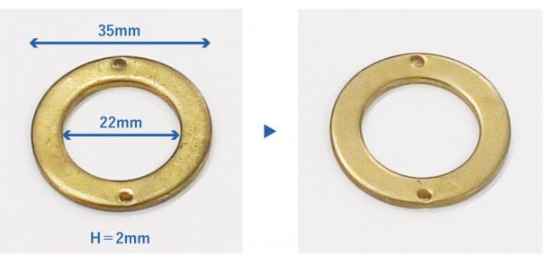

Tank Size

Capacity:5L

Related Products

-

Yamashina Seiki e-DRAIN Drain Cooler

-

Yamashina Seiki Flange Drill Tapping Machine

-

Yamashina Seiki Air Cooler

-

Yamashina Seiki Tractor Tube Both Ends Processing Machine

-

Yamashina Seiki Horizontal Column Swivel Type 5-axis Machining Center MQL Type Crankshaft Oil Hole Drilling Machine

-

Yamashina Seiki Tabletop R Chamfering Machine Edgenein (Edge Nine)