Yamato Electric

Yamato Electric Cylinder Jacket

Manufacturer: Yamato Electric Co., Ltd.

Model: Cylinder Jacket

Cylinder Jacket

What is a Cylinder Jacket?

It is an insulation cover for injection molding machines, extrusion machines, etc., that can reduce electricity consumption.

Features

- Since they are custom-made, they have a high degree of adhesion and excellent heat retention (insulation) effect.

- The structure is designed for easy installation using belts with dedicated hook metal fittings, requiring no tools, making the attachment and removal of the jacket simple. (Velcro specifications are also available.)

- They can be used for a long period of time without running costs, provided there are no external factors (snagging, tearing, etc.).

Benefits

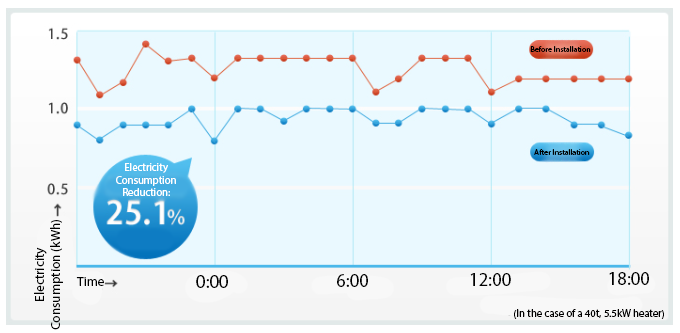

- Electricity Cost: Reduces electricity consumption of the cylinder’s heater section by approximately 20-50% (based on our company’s results).

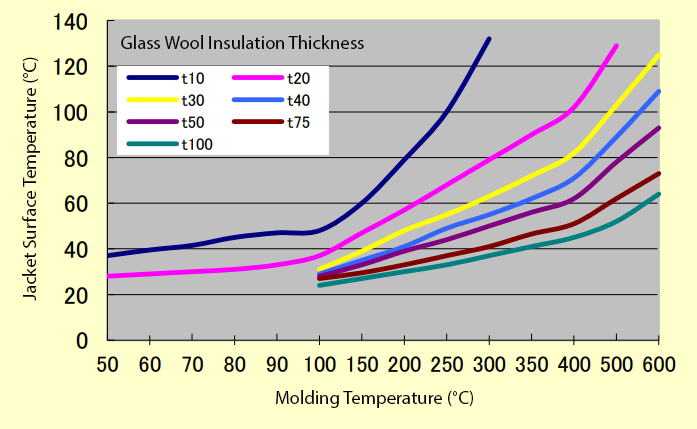

- Working Environment / Safety: The surface temperature of the jacket after installation drops significantly from the molding temperature, contributing greatly to worker safety. (e.g., 250°C -> slightly below 60°C).

- Quality: The heat retention effect of the jacket creates stable molding conditions.

- Cooling Costs: Suppresses radiant heat, preventing the room temperature from rising.

- CO2 Reduction: Reduces CO2 emissions by 0.42kg per 1kWh saved. (Source: Ministry of the Environment, based on the calculation method for greenhouse gases from electricity.)

For Injection Molding Machines and Extrusion Molding Machines

Cylinder Jacket (ECO)

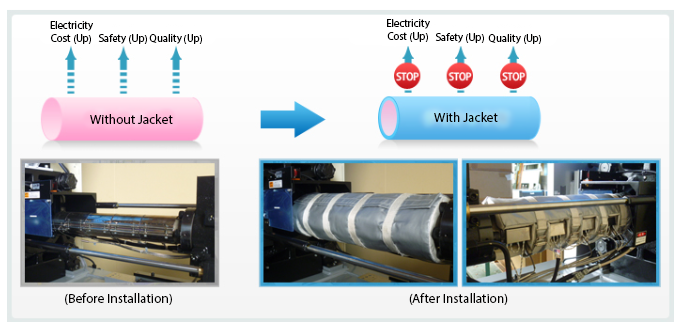

Radiant heat from the cylinder is causing an escape of “Electricity Cost, Safety, and Quality.”

- Custom-made for a Perfect Fit!!

- Easy Installation! Just fasten with the dedicated band!!

(Velcro specifications are also available.) - Can be used for a long period of time, barring external factors!!

- Quickly lower the temperature with the air coupler for cooling!!

(This is an option. Please see the back side for details.)

★ Electricity Cost: Reduces the electricity consumption of the cylinder’s heater section by approximately 20-50% (based on our company’s results).

★ Working Environment / Safety: After installation, the jacket surface temperature drops significantly below the molding temperature, contributing greatly to worker safety. (See graph below)

★ Quality: The heat retention (insulation) effect of the jacket creates stable molding conditions.

★ Cooling Costs: Suppresses radiant heat, preventing the room temperature from rising.

★ CO2 Reduction: Reduces CO2 emissions by 0.42kg per 1kWh saved. (Source: Ministry of the Environment, based on the calculation method for greenhouse gases from electricity.)

Cylinder Jacket Materials (Standard Specifications)

| Outer Surface (Exterior Side) | Glass Cloth (Heat resistance 260°C) |

|---|---|

| Insulation Material | Glass Wool Mat (t15) Silica Mat (t15) |

| Inner Surface (Heater Side) | Silica Cloth (Heat resistance 900°C) |

| Hook-and-Loop Fastener (Velcro) | Nylon (Heat resistance 130°C) |

Surface Temperature After Cylinder Jacket Installation (Room Temperature 20°C)

Cylinder Jacket Installation Example

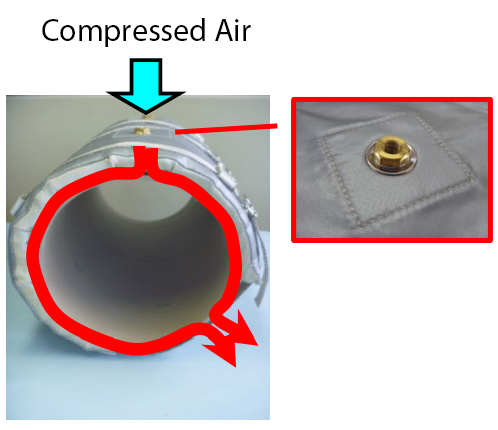

Cylinder Jacket with Air Coupler (Patent Pending)

“I want to use a Cylinder Jacket, but…””I want to forcibly lower the cylinder temperature when changing molds/settings.”We respond to the demands of such users!!

Adopting an Air Coupler for Cooling!!

The cylinder temperature is lowered by attaching the optional Air Coupler.

The compressed air injected from the Air Coupler fills the 30mm thick insulation material and is then exhausted as high-temperature air from the gap between the jacket and the cylinder while cooling the cylinder surface.

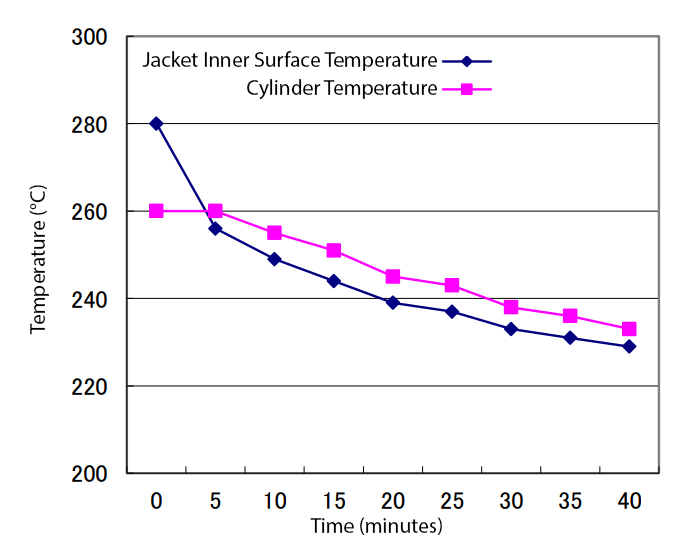

Temperature Reduction Test Results using the Air Coupler

- Equipment: Injection Molding Machine 850t.

- Temperature: Initial Temperature 2.

- Air Pressure: 0.2 MPa.

- Number of Couplers: 6 locations.

- Time: 40 minutes.

| Time (min) | Temperature (°C) | |

|---|---|---|

| Jacket Inner Surface | Cylinder | |

| 0 | 280 | 260 |

| 5 | 256 | 260 |

| 10 | 249 | 255 |

| 15 | 244 | 251 |

| 20 | 239 | 245 |

| 25 | 237 | 243 |

| 30 | 233 | 238 |

| 35 | 231 | 236 |

| 40 | 229 | 233 |