- Home

- Products

- Yamato Electric MSK/ MAK Series Vinyl Blade Coating (Double Coating) Flexible FCK-Specific Connector

Yamato Electric

Yamato Electric MSK/ MAK Series Vinyl Blade Coating (Double Coating) Flexible FCK-Specific Connector

Manufacturer: Yamato Electric Co., Ltd.

Model: MSK/ MAK Series

Vinyl Blade Coating (Double Coating) Flexible FCK-Specific Connector MSK MAK

- This connector is specifically designed for FCK (P20), considering liquid resistance and cutting powder resistance.

- Flexible connectors, excluding those with springs, can also be used as FCK connectors. (Please contact us for more details.)

- Liquid and dustproof structure: Protection rating IP67 (See the compatibility chart for P12 flexible connectors and connectors).

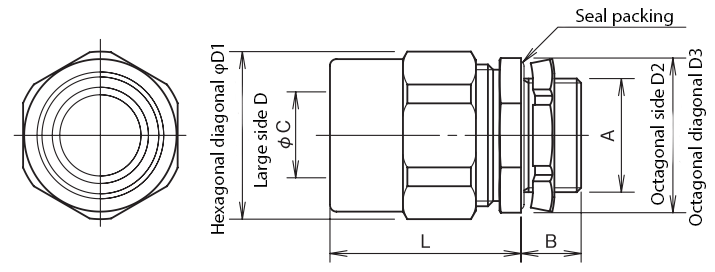

Straight Connector MSK

Unit: mm

| Symbol | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Designation | Thick Copper Thread A | B | Inner diameter C | Length before tightening L | Side D | Diagonal D1 | Side D2 | Diagonal D3 | Weight (g) | ||||

| Electric Cable Thread Designation | Pipe Flat Thread Designation | Threaded Hole Diameter | |||||||||||

| MSK-10-16 | CTG 16 | G 1/2 | 21 | 14 | 8.2 | 40 | 27 | 29 | 29 | 29 | 108 | ||

| MSK-12-16 | CTG 16 | G 1/2 | 21 | 14 | 10.7 | 41 | 27 | 29 | 29 | 29 | 100 | ||

| MSK-16-16 | CTG 16 | G 1/2 | 21 | 14 | 14 | 45.5 | 32 | 32 | 35 | 32 | 147 | ||

| MSK-16-22 | CTG 22 | G 3/4 | 27 | 14 | 14 | 45.5 | 32 | 35 | 36 | 39 | 165 | ||

| MSK-22-22 | CTG 22 | G 3/4 | 27 | 14 | 18.9 | 45.5 | 36 | 39 | 36 | 39 | 155 | ||

| MSK-28-28 | CTG 28 | G 1 | 34 | 16 | 24.5 | 49 | 46 | 49 | 46 | 50 | 295 | ||

| MSK-36-36 | CTG 36 | G 1 1/4 | 42 | 18 | 33.1 | 50.5 | 55 | 59 | 54 | 58.5 | 354 | ||

| MSK-42-42 | CTG 42 | G 1 1/2 | 48 | 18 | 38.8 | 56 | 60 | 65 | 60 | 65 | 425 | ||

| MSK-54-54 | CTG 54 | G 2 | 60 | 20 | 49.4 | 59.5 | 75 | 81 | 75 | 81 | 700 | ||

| Material | Main body: Zinc Alloy Die-Cast | ||||||||||||

| Remarks: | |||||||||||||

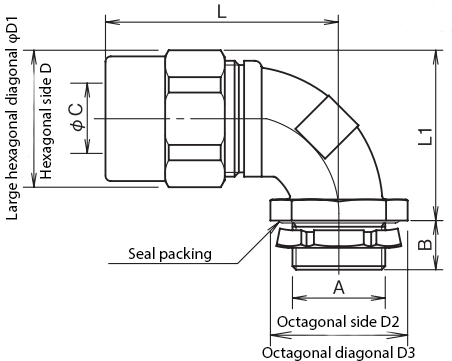

90° Angle Connector MAK

| Symbol | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Designation | Thick Copper Thread A | B | Inner diameter C | Length before tightening L | L1 | Side D | Diagonal D1 | Side D2 | Diagonal D3 | Weight (g) | |||

| Electric Cable Thread Designation | Pipe Flat Thread Designation | Threaded Hole Diameter | |||||||||||

| MAK-10-16 | CTG 16 | G 1/2 | 21 | 14 | 8.2 | 55 | 33 | 27 | 29 | 27 | 29 | 127 | |

| MAK-12-16 | CTG 16 | G 1/2 | 21 | 14 | 10.7 | 57.5 | 37 | 27 | 29 | 27 | 29 | 124 | |

| MAK-16-16 | CTG 16 | G 1/2 | 21 | 14 | 14 | 61 | 40 | 32 | 35 | 27 | 29 | 178 | |

| MAK-16-22 | CTG 22 | G 3/4 | 27 | 14 | 14 | 66.5 | 42 | 32 | 35 | 36 | 39 | 201 | |

| MAK-22-22 | CTG 22 | G 3/4 | 27 | 14 | 18.9 | 67 | 49 | 36 | 39 | 36 | 39 | 225 | |

| MAK-28-28 | CTG 28 | G 1 | 34 | 16 | 24.5 | 74.5 | 57 | 46 | 49 | 46 | 50 | 295 | |

| MAK-36-36 | CTG 36 | G 1 1/4 | 42 | 18 | 33.1 | 79.5 | 65 | 55 | 59 | 54 | 58.5 | 524 | |

| MAK-42-42 | CTG 42 | G 1 1/2 | 48 | 18 | 38.1 | 89.5 | 73 | 60 | 65 | 60 | 65 | 686 | |

| MAK-54-54 | CTG 54 | G 2 | 60 | 20 | 49.4 | 104 | 91 | 75 | 81 | 77 | 81 | 1165 | |

| Material | Main body: Zinc Alloy Die-Cast | ||||||||||||

| Remarks: | |||||||||||||

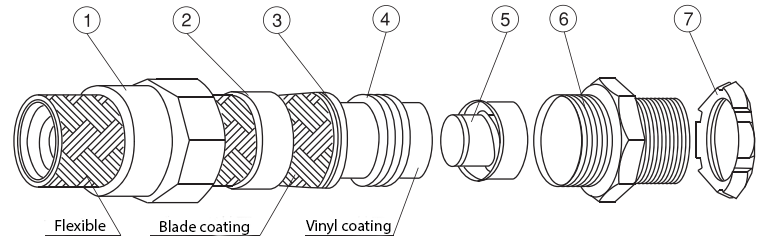

Assembly Procedure for Vinyl Blade Coated Flexible FCK and Dedicated Connectors

1. Component Composition

- Cover nut

- Slide ring

- Taper ring

- Tightening ring

- Guide collar

- Main body (MSK) ※Seal packing embedded in the main body

- Lock nut

2. Assembly Instructions

- Cut the flexible conduit to the required length. (Wrap tape at the cutting point before cutting.)

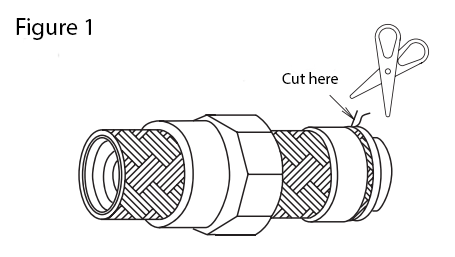

- With the tape still in place, use scissors to cut away the entire circumference of the blade that is biting into the vinyl at the cut section. [Photo 1] [(This makes the work in (4) easier)]

- Pass the flexible conduit through Cover Nut and Slide Ring. Pay attention to the direction of the Slide Ring at this time. (The thicker wall is on the Cover Nut side. Refer to Part Components.)

- Remove the tape and shift the blade so that about of the vinyl sheathing is visible. [Photo 2]

- Insert the Taper Ring into the gap between the blade and the vinyl sheathing so that the end of the blade is positioned close to the step of the Taper Ring.

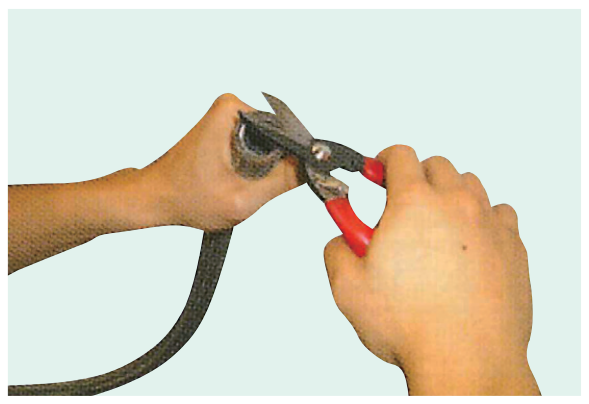

- Pull the Slide Ring toward the Taper Ring side. [Photo 3]

- Cut off the blade protruding from the gap between the Slide Ring and the Taper Ring with scissors, etc. [Figure 1]

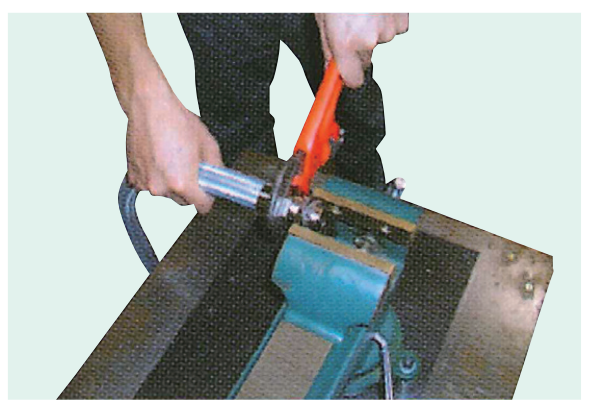

- Pass the Clamping Ring over the vinyl sheathing, and screw the Guide Collar into the flexible conduit inner diameter. [Photo 4]

Pull the Cover Nut toward the Guide Collar side. (Pulling it while rotating the Cover Nut will make the work easier.) - Hold the Connector Body and tighten the Cover Nut. [Photo 5]

Note: The structure is such that the blade is secured by tightening the Cover Nut firmly; the blade will slip out if it is temporarily tightened. Be sure to tighten the Cover Nut securely to the Connector Body once.

| Photo 1 | Photo 2 | Photo 3 | Photo 4 | Photo 5 |

|---|---|---|---|---|

|  |  |  |  |

Related Products

-

Yamato Electric MSN Series Thin Steel Conduit Threadless Coupling Connector

-

Yamato Electric Pg thread straight connector MS-PG

-

Yamato Electric 90° Angle Connector MA

-

Yamato Electric RPGE-B Series Rotating Setup Connector (Flange Type)

-

Yamato Electric RAG Series Rotary Adapter

-

Yamato Electric SPRS-11G