Taseto

TASETO KEIKO CHECK Fluorescent Penetrant Inspection Materials

Product Made In Japan

Manufacturer: TASETO

Model: KEIKO CHECK

TASETO KEIKO CHECK, the fluorescent penetrant inspection material, detects any minute defects or flaws accurately.

KEIKO CHECK Inspection should be done under Black Light (ultraviolet lamp).

Three types of TASETO KEIKO CHECK, water washable, post emulsifiable, and solvent removable fluorescent types, are available.

The developer includes non-aqueous type, dry powder type, and aqueous type, and each has its advantages.

| Types | Symbols | Characteristics | Applications |

|---|---|---|---|

| Water washable penetrant | N-21P | Hydrophobic type | For smooth surface |

| L-2 | Higher sensitivity than N-21P. | ||

| N-180P | Water based type | For low-precision inspection | |

| High sensitivity water washable penetrant | N-2P | High fluorescent brightness. Inspection is possible without a developer. | General testing |

| N-3P | Higher sensitivity than N-2P. | Precision testing | |

| N-4P | Higher sensitivity than N-3P. | High-precision testing | |

| N-5P | Higher sensitivity than N-4P. | Ultra-high precision testing | |

| Post emulsifiable penetrant | AP-5 AP-6 | For precision inspection. Use AE-56 as emulsifier. Suitable for testing fine hair cracks. | Ultra-high precision testing |

| Emulsifier | AE-56 | Used with AP-5 or AP-6. | For post emulsifiable fluorescent Penetrant |

| Non-aqueous developer | FD-S | Large suction force of penetrant Quick drying. | Partial testing of large-size parts. |

| Dry developer | ADD-456 | White fine dry powder. | For detecting very fine flaws. |

| Wet developer (aqueous) | ADW-456 | Used by dispersing white fine powder in water. | Suit for penetrant testing equipment. |

Packing units

420 ml aerosol (N-3P)

4-L can, 18-L can or 200-L drum

Fluorescent Penetrant Inspection Materials

TASETO KEIKO CHECK

Applications

Mass-produced small parts, threads, keyways, and other acute corners, and rough surfaces.

Features

1. Good fluorescent brightness and flaw detectability.

2. Usable with a variety of developers, thus widening the range of applications.

3. N-series fluorescent penetrants have self-developing action. Developers are not needed;

however, the use of a developer enhances the flaw detectability.

4. N-21P fluorescent penetrant is optimum for decreasing the drainage cost.

How to Use

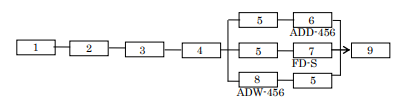

Post emulsifiable fluorescent penetrant testing.

Water washable fluorescent penetrant testing.

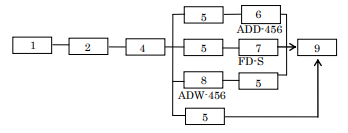

Solvent removable fluorescent penetrant testing.

![]()

Key:

1. Pre-cleaning

2. Penetration

3. Emulsification

4. Rinsing (with water)

5. Drying

6. Dry powder developer application

7. Non-aqueous developer application

8. Wet developer application

9. Interpretation

10. Removal (with solvent remover)