Japan, Kakuta

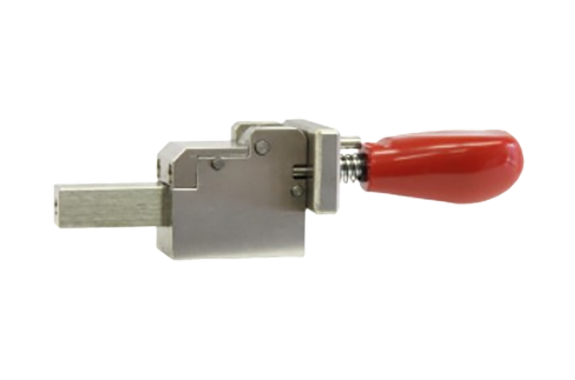

Kakuta KCP-22ST Dual Clamp

Product Made in Japan

Manufacturer: Kakuta Co., Ltd

Model: KCP-22ST

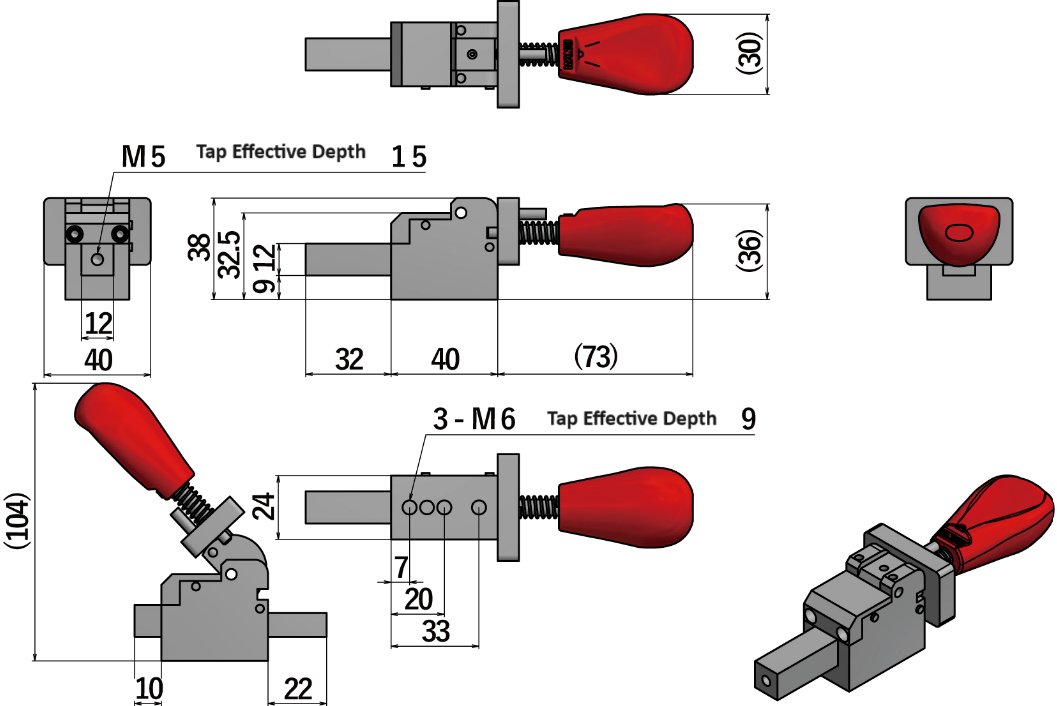

DualClamp KCP-22ST(Straight Line w/Lock)

| Category | Dual Clamp |

|---|---|

| Model Number | KCP-22ST |

| Weight | 348g |

| Holding Capacity | 2.5kN(250kgf) |

| Material | Stainless Steel+Others Materials |

| Mounting Method | Flange Base |

| Surface finish | Body/Cam/Connecting arm/Slide bar:Stainless Steel(Surface is untreated),SPRING:SUS304-WPB , Grip:Plastic(P.P) |

CAD data

Straight Line w/Lock

Feature

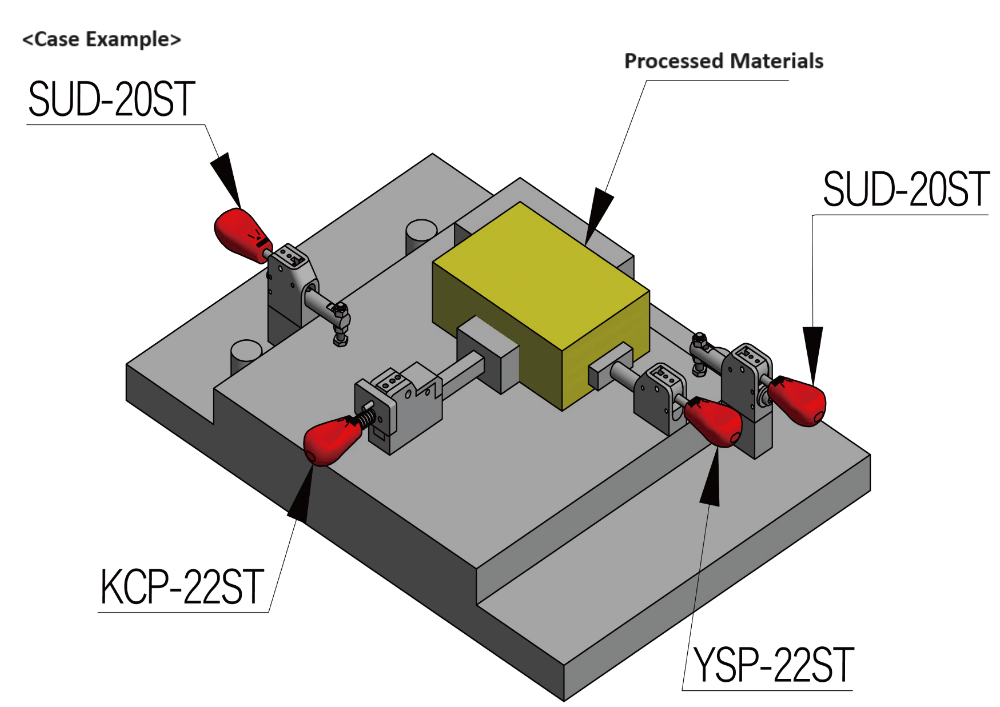

Dual clamp realizes high safety and high performance by having a cam mechanism in addition to toggle clamp that can hold a sliding axis by cam.

Dual Clamp have been successfully tested for more than 1 million cycles and hold a workpiece stably for long time that reduce the cost of replacement.

There is a version with safety lock to prevent unclamp by vibration, backlash and mis-operation.

- The grip has been developed based on ergonomics fits to hands and reduce physical burden.

- Need to adjust the bolt length before use.

- Do not use in lathe/turning and at high tempareture as welding.

Caution

- The holding capacity is for reference.

- The holding capacity decrease toward the tip of clamp arm.

- Do not give the shock, vibration and internal pressure which causes a failure.

- Caution to pinch the fingers.

Dual Clamp Instruction

Read before use

<Check before use>

- The holding capacity noted in catalog is for reference.

- The value cannot be guaranteed as it bepends on the condition of use.

- Use caution as the holding force will drop due to depending on the holding position, bolt adjustment and type of bolt uses.

- When selecting and using clamps, allow enough margin for the holding capacity.

<Precaution>

- Mounting Method: Mount by fixing bolts securely.

- Holding Position: It does not hold or clamp on the way of actuating. It only can hold at holding position. (Toggle and cam mechanism at work)

- Lubrication: Apply oil to the slides and friction parts on a regular basis. Chip removing: When using in place where there are chips, remove chips around the main unit, especially the rivets and rotating parts by using an airgun before clamping & unclamping.

- Inspection: Inspect regularly for bolts and nuts that secures the body and clamp arm.

- Operating environment: Using in the corrosive or inappropriate environment causes mulfanction, damage and transform.

- Precaution: Do not insert your hands and fingers in range of the action and wear protective gloves for safety when mounting or operation. Do not use at exceed the holding capacity.

<Note>

- Specification will change for improvement without notice.

- The holding capacity and durability noted in catalogue is maximum value.

- The holding capacity will decrease due to the condition of usage.

- Apply oil to the slides and friction parts on a regular basis.

- Wear protective gloves for safety when mounting or operation.