Fukudaco, Japan

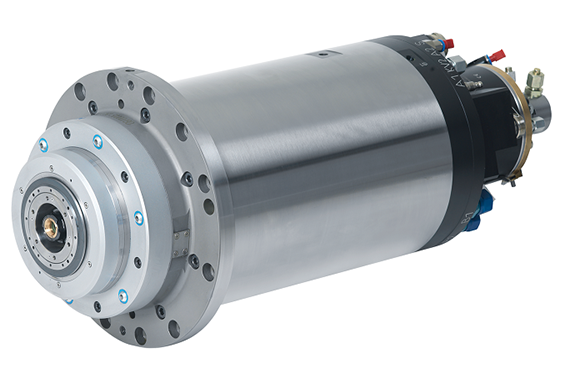

Fukudaco F-Mill Spindle with FANUC Motor

Manufacturer: Fukudaco

Model: F-Mill

Overview

GMN has added the new F-Mill series to its lineup of milling spindles. The F-Mill spindles build on the proven knowledge and experience gained from the HCS series and are equipped with FANUC’s Bil112-type asynchronous motors. Using FANUC motors allows the operation of GMN spindles with FANUC’s control systems. Depending on the spindle’s maximum rotational speed, two bearing lubrication methods are available: grease lubrication and oil-air lubrication.

Applications

- Cutting tool spindles

- Machining centers

- Grinding and drilling operations

Features

- Automatic tool change: Clamping system with an unclamped unit

- Tool interface: HSK-A63 (compliant with DIN69893)

- Taper cleaning and air purge function

- Coolant through housing

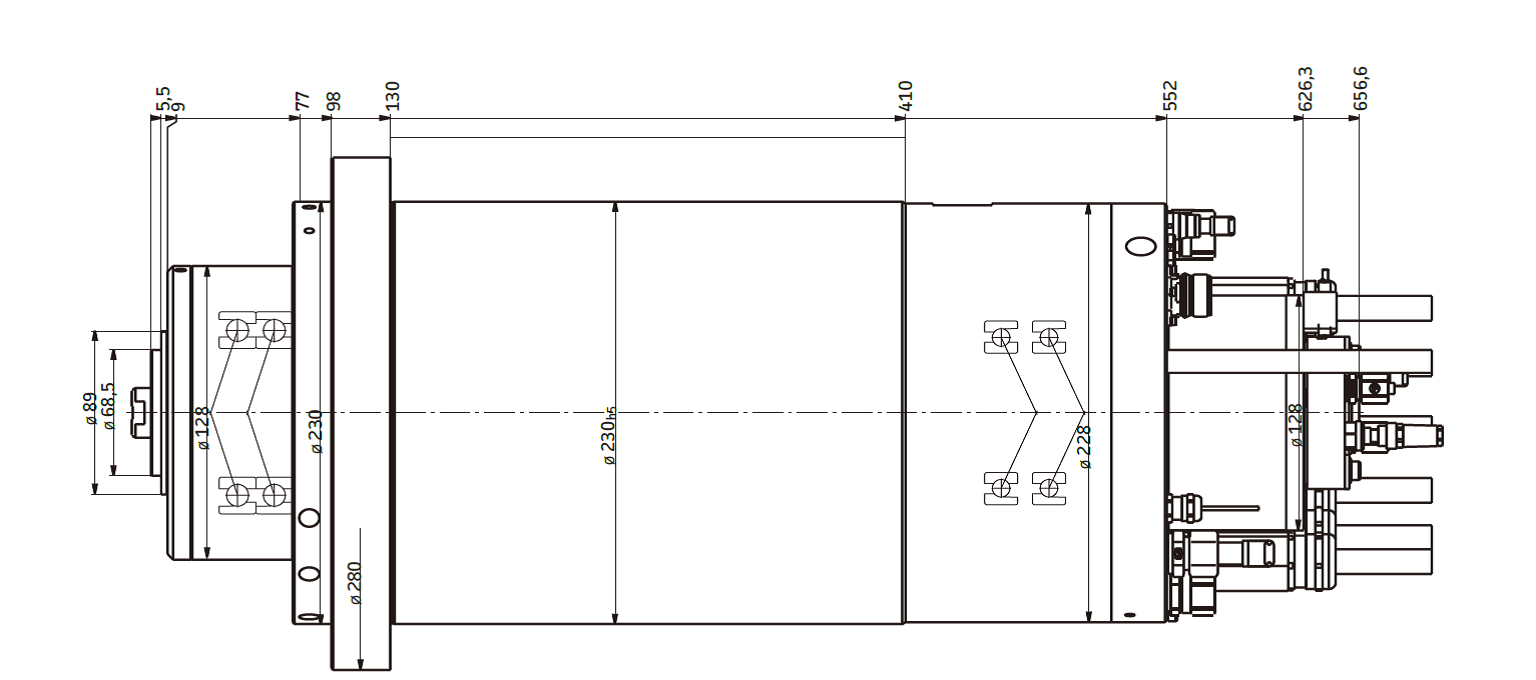

Dimensions

The F-Mill HCS230 series shares common external dimensions.

Specification

| Spindle Type | HCS 230g-12000/25 | HCS 230g-15000/25 | HCS 230g-16000/11 | |

|---|---|---|---|---|

| FANUC Asynchronous Motor | BiI 112L/15000-B Type M | BiI 112L/15000-B | BiI 112L/20000-B | |

| Maximum RPM | 12000 [min -1 ] | 15000 [min -1 ] | 16000 [min -1 ] | |

| Low-Speed Winding | S1 Output | 15 [Kw] | 15 [Kw] | 7.5 [Kw] |

| S1 Output RPM | 1300~4000 [min -1 ] | 1400~4000 [min -1 ] | 895~5000 [min -1 ] | |

| S1 Torque | 110 [Nm] | 102 [Nm] | 80 [Nm] | |

| S1 torque speed | ~1300 [min -1 ] | ~4000 [min -1 ] | ~895 [min -1 ] | |

| High-Speed Winding | S1 Output | 25 [Kw] | 25 [Kw] | 11 [Kw] |

| S1 Output RPM | 4000~11000 [min -1 ] | 4000~11000 [min -1 ] | 2450~11000 [min -1 ] | |

| S1 Torque | 59.7 [Nm] | 59.7 [Nm] | 42.9 [Nm] | |

| S1 torque speed | 4000 [min -1 ] | 4000 [min -1 ] | 1500~2450 [min -1 ] | |

| FANUC inverter | αiSP45 HV-B | αiSP45 HV-B | αiSP 22-B | |

| Bearing Lubrication Method | Grease lubrication | Grease lubrication | Grease lubrication | |

| Front bearing inner diameter | 70 [mm] | 70 [mm] | 70 [mm] | |

| Tool Interface | HSK-A63 | HSK-A63 | HSK-A63 | |

| Tool retraction force | 18 [kW] | 18 [kW] | 18 [kW] | |

| Tool retraction position detection signal output | Analog or digital | Analog or digital | Analog or digital | |

| Static stiffness | Axial | 220 [N/µm] | 200 [N/µm] | 200 [N/µm] |

| radial | 460 [N/µm] | 460 [N/µm] | 460 [N/µm] | |

| Coolant Through Housing | 1 [MPa] | 1 [MPa] | 1 [MPa] | |

| Spindle Type | HCS 230g-16000/18.5 | HCS 230g-16000/25 | HCS 230-20000/18.5 | |

|---|---|---|---|---|

| FANUC Asynchronous Motor | BiI 112S/20000-B | BiI 112L/20000-B | BiI 112L/25000-B Type M | |

| Maximum RPM | 16000 [min -1 ] | 16000 [min -1 ] | 20000 [min -1 ] | |

| Low-Speed Winding | S1 Output | 11 [Kw] | 25 [Kw] | 15 [Kw] |

| S1 Output RPM | 2300~6000 [min -1 ] | 2800~3500 [min -1 ] | 1570~4500 [min -1 ] | |

| S1 Torque | 50 [Nm] | 85.3 [Nm] | 91.2 [Nm] | |

| S1 torque speed | ~2300 [min -1 ] | ~3500 [min -1 ] | ~1570 [min -1 ] | |

| High-Speed Winding | S1 Output | 18.5 [Kw] | 25 [Kw] | 18.5 [Kw] |

| S1 Output RPM | 6000~12000 [min -1 ] | 5000~13000 [min -1 ] | 6500~20000 [min -1 ] | |

| S1 Torque | 29.4 [Nm] | 47.7 [Nm] | 27.2 [Nm] | |

| S1 torque speed | 6000 [min -1 ] | 2500~5000 [min -1 ] | 3000~6500 [min -1 ] | |

| FANUC inverter | αiSP 26-B | αiSP 37-B | αiSP 30-B | |

| Bearing Lubrication Method | Grease lubrication | Grease lubrication | Oil-air lubrication | |

| Front bearing inner diameter | 70 [mm] | 70 [mm] | 70 [mm] | |

| Tool Interface | HSK-A63 | HSK-A63 | HSK-A63 | |

| Tool retraction force | 18 [kW] | 18 [kW] | 18 [kW] | |

| Tool retraction position detection signal output | Analog or digital | Analog or digital | Analog or digital | |

| Static stiffness | Axial | 200 [N/µm] | 200 [N/µm] | 120 [N/µm] |

| radial | 460 [N/µm] | 460 [N/µm] | 400 [N/µm] | |

| Coolant Through Housing | 1 [MPa] | 1 [MPa] | 1 [MPa] | |

| Spindle Type | HCS 230-20000/30 | |

|---|---|---|

| FANUC Asynchronous Motor | BiI 112l/25000-B | |

| Maximum RPM | 20000 [min -1 ] | |

| Low-Speed Winding | S1 Output | 26 [Kw] |

| S1 Output RPM | 2800~6000 [min -1 ] | |

| S1 Torque | 88.7 [Nm] | |

| S1 torque speed | ~2800 [min -1 ] | |

| High-Speed Winding | S1 Output | 30 [Kw] |

| S1 Output RPM | 5400~15000 [min -1 ] | |

| S1 Torque | 53.1 [Nm] | |

| S1 torque speed | 5400 [min -1 ] | |

| FANUC inverter | αiSP 75HV-B | |

| Bearing Lubrication Method | Oil-air lubrication | |

| Front bearing inner diameter | 70 [mm] | |

| Tool Interface | HSK-A63 | |

| Tool retraction force | 18 [kW] | |

| Tool retraction position detection signal output | Analog or digital | |

| Static stiffness | Axial | 120 [N/µm] |

| radial | 400 [N/µm] | |

| Coolant Through Housing | 1 [MPa] | |

Related Products

-

Organo Granular Activated Carbon Decolorization Equipment, Activated Carbon Regeneration Equipment

-

SAKUSAKU TNGG160404-R Turning Insert 60° Triangular/Negative

-

Seishin SKL Series Engineering Plastic Knocker

-

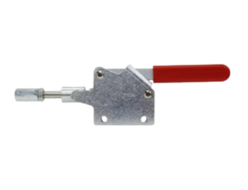

Kakuta No.51BSM Straight Line Clamp

-

Dynaflo Slurry Pump 2 : 1 Series Model K6x2 ( 15A 1/2″ )

-

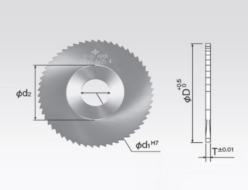

Okazaki Seiko SMS Solid Carbide Metal Slitting Saws

REQUEST QUOTATION

PAYMENT

MAKER

TOOLS & EQUIPMENT

Lifting

Eagle Clamp | Eagle Jack | Elephant | Endo Kogyo

Kanetec | Jung | KITO

Kondotec | Miki Netsuren | Sanei Seiki

Hand Tools

Bix | Miyakawa | Nakatani Kikai | Ogura |

Super Tool | TONE | Yutani

Tape

Kamoi | Kikusui | Nirei | Teraoka

Measurement

Hasegawa | Kawaki | Kett | KGK | Line Seiki | Nagano Keiki

Niigata Seiki | Obishi Keiki | RSK | Ryoden Shonan | Sanko

Showa Seisakusho | Showa Sokki

Safety Tools

Fujii Denko | Shigematsu | Titan

Welding

Asahi Weldex | Daihen | Koike | Nissan Tanaka

Other Tools

Hammer Caster | Matsuda Seiki | Sanritsu

Sanyutec | Toyo Kensetsu Kohki

Yamari

PLANT FACILITIES

Facilities

Acokk | Bunkaboeki | Horiuchi | Konan | Murakoshi

Murakoshi Industries | Nesstech | Nikkin Flux

NFK | Organo | Taiyo Parker

Pump

Honda Kiko | Kyowa | Musashino

Valve

Astam | Kyowa Iron | Nachi | Nippon Daiya | Sawada

Wasino Kiki | Yoshitake

Electricity

Asahi Bagnal | Kokosha | U_RD

CONSTRUCTION

Concrete Work

EXEN | Japan Life | Mikasa | Taiheiyo

High Tension Bolt

Dong Ah | KPF | Nippon Fastener

Bolt & Nut & Washer

Hard Lock | Mori Kozai

Nakaumi | Otani | Toneji

STEEL MATERIAL

Steel & other Material

Dongil | JIS Standard | DSR | Winoa IKK