Fukudaco, Japan

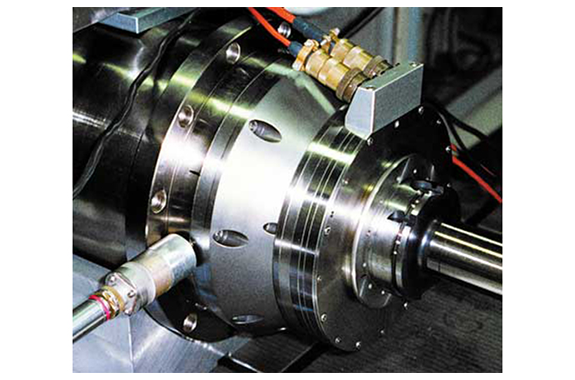

Fukudaco Active Balancing System

Manufacturer: Fukudaco

Overview

It reduces vibrations caused by various factors, including imbalances due to workpiece shape, tooling, and wear.

Applications

- Grinding

- Lathes

- Industrial fans

Features

- Balance correction completes in just a few seconds without stopping rotation.

- The ring-type design allows for relatively easy retrofitting.

- Achieves a balance level of 1.0G or lower.

- Enables quick and automatic balancing without stopping rotation.

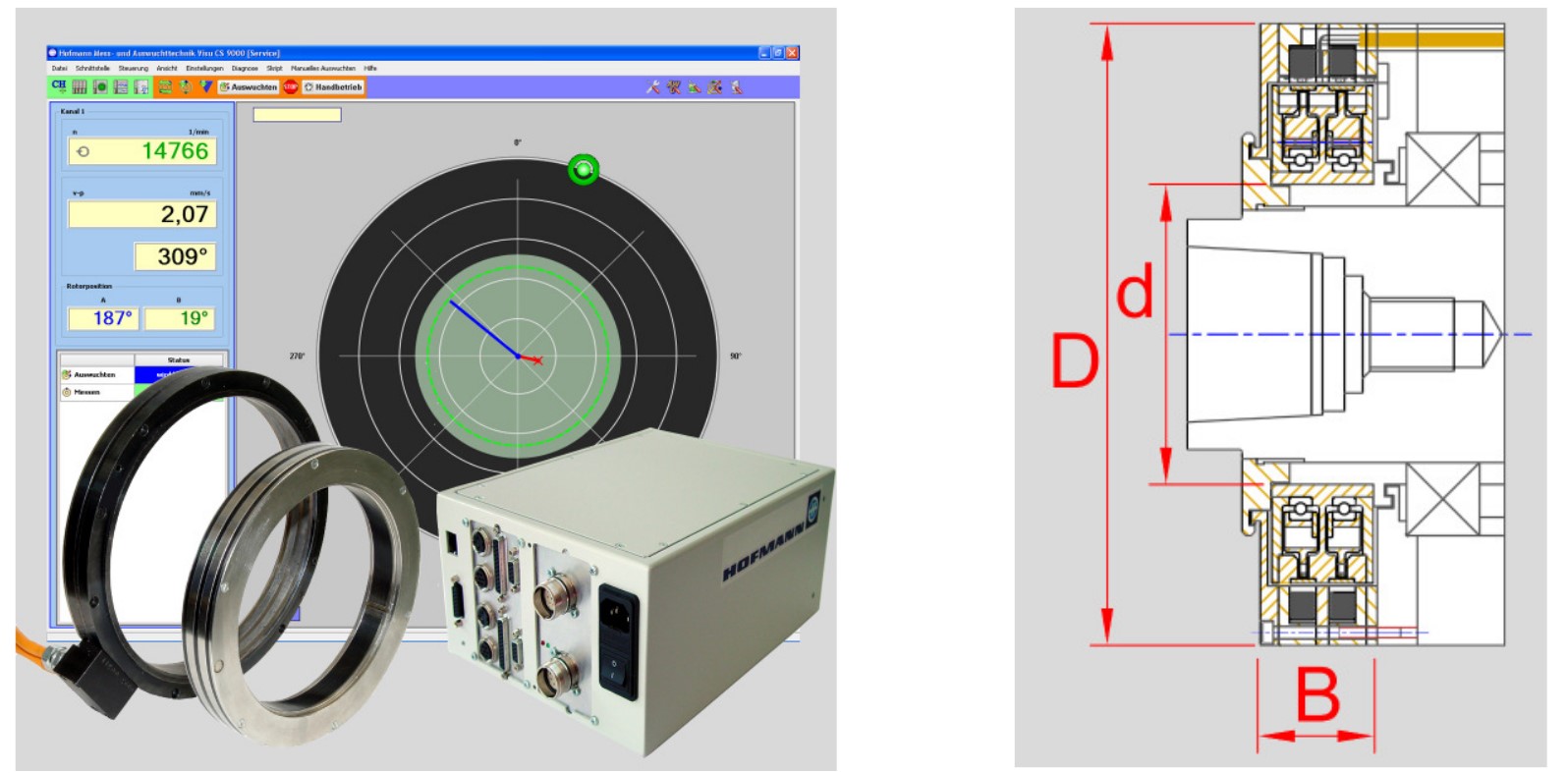

Active Balancing System Operating Principle

By reducing vibrations and dynamic runout, the active balancing system enhances machining accuracy. Resonance is minimized, thereby extending tool life. The system allows for increased rotational speeds, leading to reduced cycle times. It also shortens setup times, thereby improving productivity. Additionally, it enhances safety through simple operation.

Benefits of Implementing a Balancing System

- Improved Machining Accuracy: Reduces vibrations and dynamic runout, enhancing overall machining precision.

- Extended Tool Life: Minimizes resonance, leading to a longer tool lifespan.

- Increased Rotational Speed: Allows higher rotational speeds, which shortens cycle times.

- Enhanced Productivity: Shortens setup times, thereby boosting productivity.

- Improved Safety: Simple operation enhances safety during use.

System Components

The active balancing system is ideal for turning operations involving asymmetric workpieces or small batch production of diverse product types.

Specification

| Series | Maximum corrected imbalance (gmm) | Maximum rotation speed (min -1 ) | Balancer ring inner diameter Φd (mm) | Overall length B (mm) | Fixed side stator coil outer diameter ΦD (mm) |

|---|---|---|---|---|---|

| 68 | 900 | 10,000 | 63.5 | 35 | 132 |

| 76 | 300 | 14,000 | 68 | 31.5 | 160 |

| 89 | 600 | 9,000 | 82 | 29 | 170 |

| 108 | 2,000 | 5,500 | 95 | 34 | 192 |

| 121 | 1,000 | 9,000 | 115 | 33 | 203 |

| 165 | 5,000 | 4,500 | 160 | 33 | 250 |

| 229 | 13,000 | 8,000 | 209.8 | 35 | 350 |

| 406 | 3,240,000 | 1,000 | 355 | 94 | 700 |

Related Products

-

Yamayo 3X Million Fiberglass Measuring Tapes

-

NAGANO KEIKI BG Process Industrial Pressure Gauges

-

Seiwa E04SR311835F SR, SRM and SRS Types Split Cores

-

Seiwa E04RC170816 RC, RM and RMX Types Non-split Cores

-

Ross Asia DMC2 series double valve Safety Cat 4 PL e, internal monitoring, manual reset

-

LPL PM-50 Universal System Clamp