Nippon Avionics Co., Ltd.

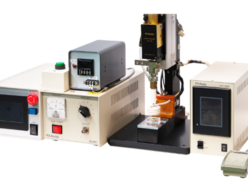

Avio SW-3500-20 Ultrasonic Metal Welding Machine

Manufacturer: Nippon Avionics Co., Ltd.

Model: SW-3500-20

Feature of SW-3500-20

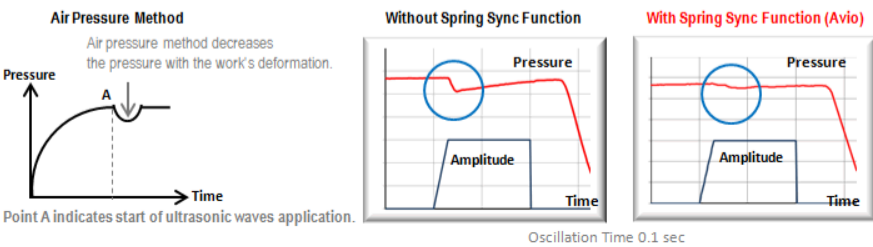

- Spring Pressure Sync Mechanism

Excellent response to the pressure variations prevents slip between horn and work, reduces ultrasonic energy loss and minimizes dust and waste.

- High Rigidity Pressure Mechanism

Maintains very small deflections to ensure uniform weld side pressure. - Unique, Original Design Ultrasonic Oscillation Frequency Automatic Tracking System.

Ensures stable vibration amplitude during high loads. - High Performance Depth Control (1μm Resolution Linear Scale)

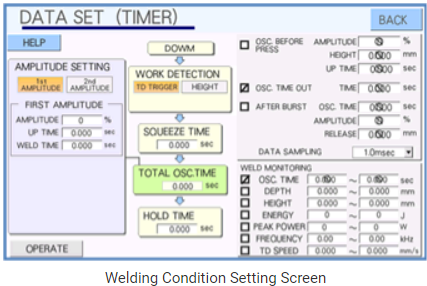

Oscillation is controlled by feedback of sinking of work and work height. - 4 Types of Oscillation Control Method

Time, Work Sinking Value, Work Height, Applied Energy

Easy Management, Easy Operation, Easy System Integration

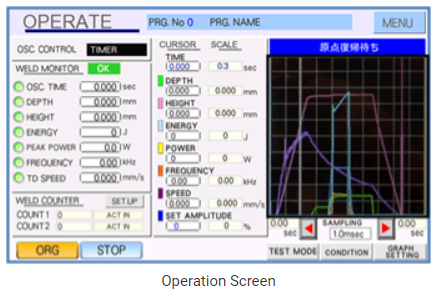

- Easy Management with Graphic Monitor Function

- Ultrasonic Peak Output

- Ultrasonic Energy

- Sinking Amount of the Work

- Work Height

- Simple Operation, Easy-to-read Display

- 7-inch LCD Touch Panel

- Intuitive Operation

- Graphic Display

- Setting and Management of Data via Serial Communication (RS-232C)

- Weld Conditions

- Monitor Value

- Judgment Result

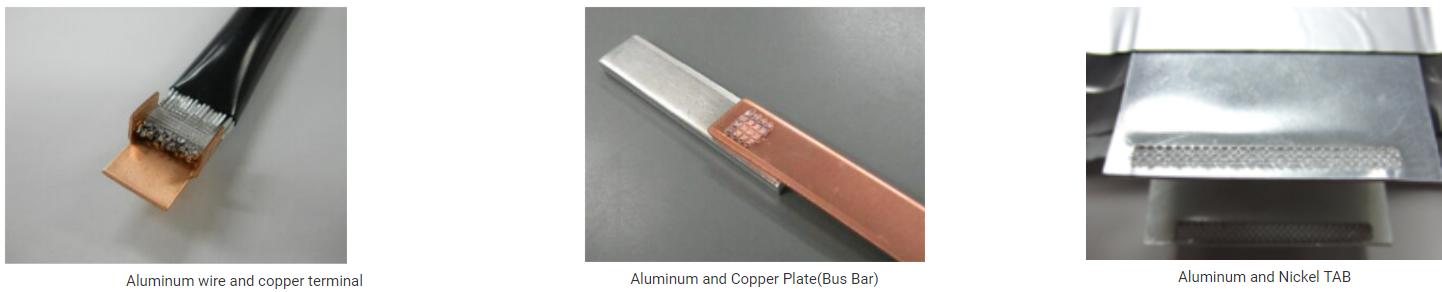

Applications

Ultrasonic Generator Specifications

| Items | SW-3500-20 |

|---|---|

| Maximum Output Power | 3,500W |

| Nominal Frequency | 20kHz |

| Amplitude Adjustment | Variable (30 – 100%, 1% step) |

| Control Mode | Time/Depth/Height/Energy |

| Power Source | AC200V 3Φ |

| Oscillation Method | Automatic Tuning Hold Master Oscillator System (ATHMOS) |

| Dimension / Weight | W250 x D450 x H375mm |

Ultrasonic Head Specifications

| Items | SH-H3K7 | medium type(custom made) |

|---|---|---|

| Pressure Follow-up Mechanism | Spring + Air | 63mmφ |

| Adjustable Pressure Range | 1,700N – 3,700N | 300~1600N |

| Stroke | 50mm | |

| Supply Air Pressure | 0.5MPa (Clean, Dry Air) | 120kg |

| Dimension / Weight | W380 x D600 x H935mm | W310 x D600 x H776 mm |

Related Products

-

Avio NRW-IN900P Resistance Welder High-Reliability Inverter

-

Avio NA-54A Hand Piece Type Head For Resistance Welder

-

Avio UI Series High Frequency Induction Heating Machine

-

Avio TCW-DP100 Pulse Heat (Hot Bar) Displacement Type

-

Avio NRW-IN400PA Resistance Welder Inverter

-

Avio NA-60A Head With Integrated Drive for Resistance Welder