Nippon Avionics Co., Ltd.

Avio NAW-6100/NAW-6000 Parallel Seam Sealer With Automatic Lid Placement

Manufacturer: Nippon Avionics Co., Ltd.

Model: NAW-6100/NAW-6000

Features of NAW-6100/NAW-6000

- PKG size: 2 to 150mm

- PKG shape: Round, square, polygonal

- Lid shape: Flat LID,Cap LID,LID with window It supports lid thickness up to 0.3 mm(model: NAW-6100)

It contributes to improve cycle time (Production efficiency)

- Automatic lid placement

- Automatic operation from lid placement to sealing.

- High speed welding (10mm/sec)

It contributes to improve yield.

- It suppresses misalignment with high-precision lid mounting accuracy.

- lid placement accuracy ±0.035mm(25×25mmPKG)

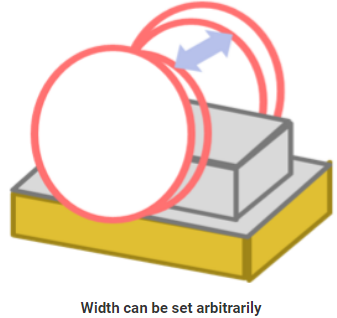

- Model NAW-6100 ensures sufficient seal width to reduce leak defects.

- It reduces heat storage and suppresses cracks.

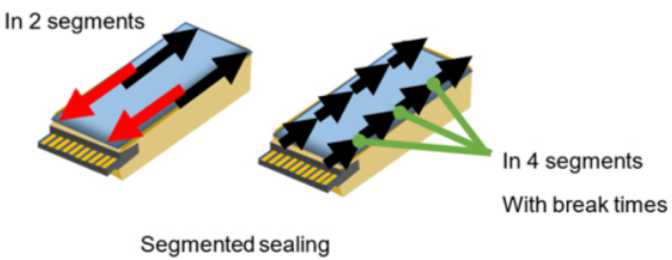

- Optimum control such as split sealing is available which minimizes stress.

Welding start position, end position, and electrode width can be specified by the user.

Functions can be selected according to the production method

- Methods of lid supply

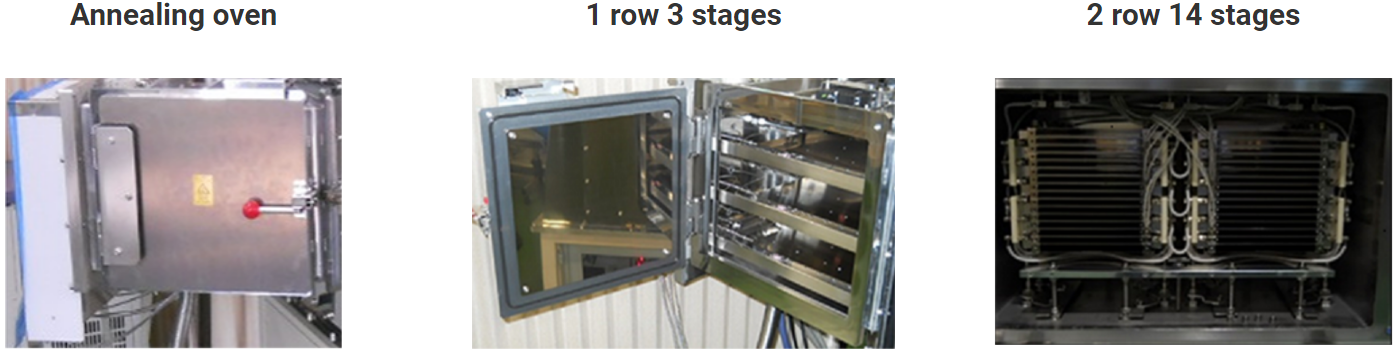

Carrier (standard), cassette, parts feeder, manual placement - Annealing oven

Placement position (left and right), number of stages, number of rows, number of pieces - Adding HEPA filter (Suppresses influence of particle)

Parallel Seam Sealer Specifications

| Items | NAW-6100 | NAW-6000 | |

|---|---|---|---|

| Applicable Size | Work | 2mm~150mm | |

| Welding Controller | Control Method | W Mode | |

| Rated Capacity | 4kVA | 2kVA | |

| Monitor | I,V,W,R | ||

| Welding Head | Head Pressure | 3~22N | 2~20N |

| Vertical Stroke | 15mm | ||

| Distance between Electrode | 2~150mm | ||

| Booth | Atmospheric Management | By dew point meter | |

| Reachable Dew Point | Less than 45℃ | ||

| Structure | Pass box, Various oven chambers are available | ||

| Lid Supply | Selectable from tray (Standard), cassette, parts feeder, and manual placement | ||

| Image Recognition | Unique algorithm | ||

| Operation | Touch panel and hard switch | ||

| Size (Reference) | W2100mm × D960mm × H2000 mm | ||

* External dimensions can be changed by existence of annealing oven or not, etc.

Related Products

-

Avio NRW-IN900P Resistance Welder High-Reliability Inverter

-

Avio SW-D Series Ultrasonic Welding Machine

-

Avio NA-54A Hand Piece Type Head For Resistance Welder

-

Avio N2 Gas Fully Automatic Parallel Seam Sealer

-

Avio TCW-315 Pulse Heat (Hot Bar) Soldering Machine General Purpose Type

-

Avio NA Series Reflow System Head