Fukuda Seiko, Japan

Fukuda SmartCheck condition monitoring device

Made in Japan

Manufacturer: Fukuda Seiko

Model: SmartCheck condition monitoring device

Features

SmartCheck is a condition monitoring device that monitors vibration and temperature.

By detecting the natural vibration frequency of each machine element at the time of failure, it is possible to detect abnormal vibrations that lead to unexpected equipment stoppages, and to detect machine elements where abnormalities have occurred.

- Wide range vibration from 0.8 ~ 10 kHz and condition monitoring with temperature of -20°C ~ +70°C

- FFT calculation is performed automatically, and an alarm is issued in two stages.

- A wide range of preset measurement templates covering various production facilities

- Even in the case of variable speed and load fluctuations, the alarm threshold is set according to each operating condition.

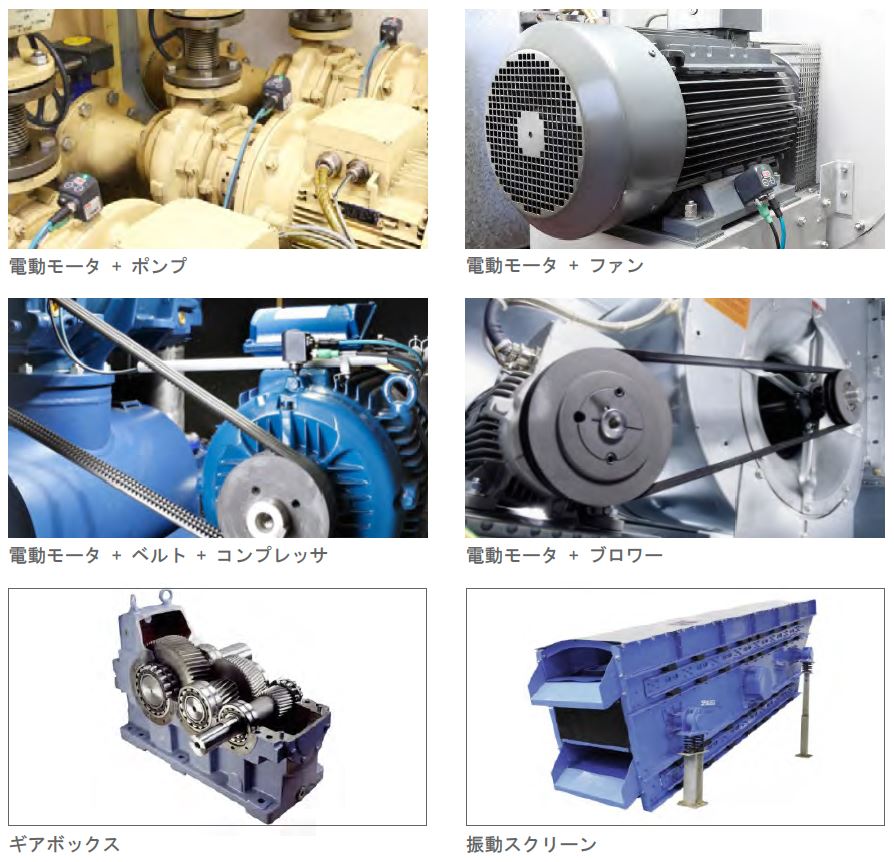

use

- Condition monitoring of all production equipment (rotating machinery)

- pump

- Motor

- fan

- gearbox

- belt

- Compressor

- Vibrating Screen

- Condition monitoring of all production equipment (rotating machinery)

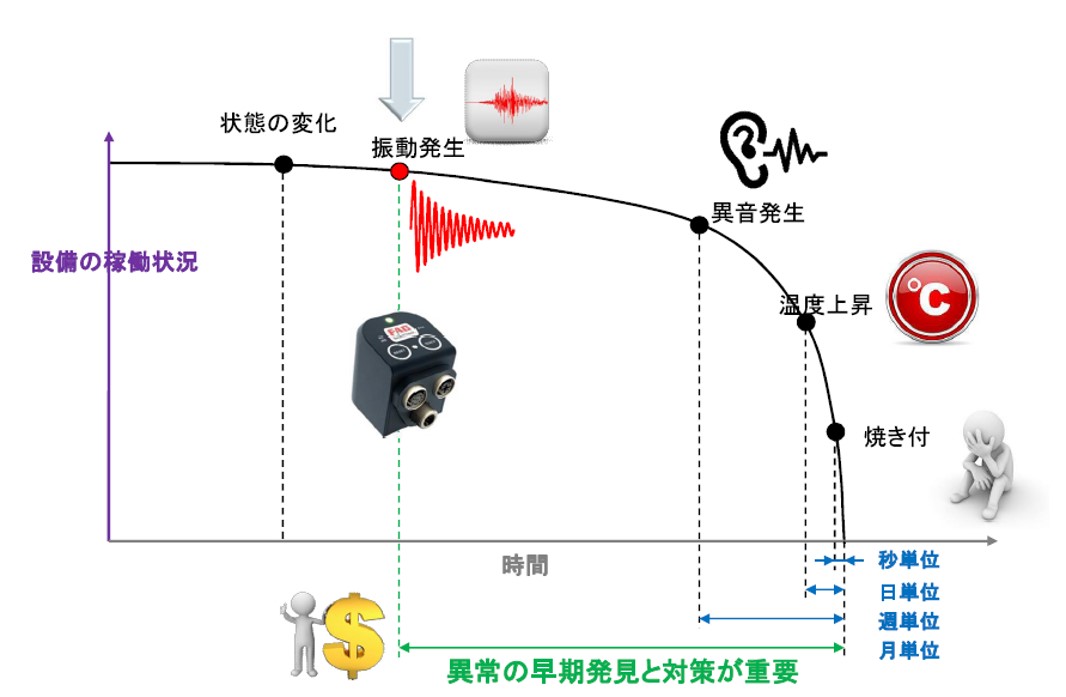

Benefits of Vibration Condition Monitoring

In the case of bearing damage, which is the cause of many production equipment stoppages, the operating status generally changes in the following order.

- 1vibration

- 2allophone

- 3temperature rise;

- 4Bearing baking

Therefore, vibration monitoring leads to early detection of equipment abnormalities.

In addition, in order to avoid unexpected equipment stoppages, bearings and other machine parts are replaced as soon as possible on an operating hour basis. As a result, even parts that can be used continuously may be discarded, leading to increased maintenance costs.

In addition, there are cases where measurement using a portable vibration meter and vibration diagnosis by auscultation rely on the skills of the examiner, so there is a concern that uniform sign management will be difficult.

For these reasons, it is recommended to perform condition-based monitoring using a vibration measuring device.

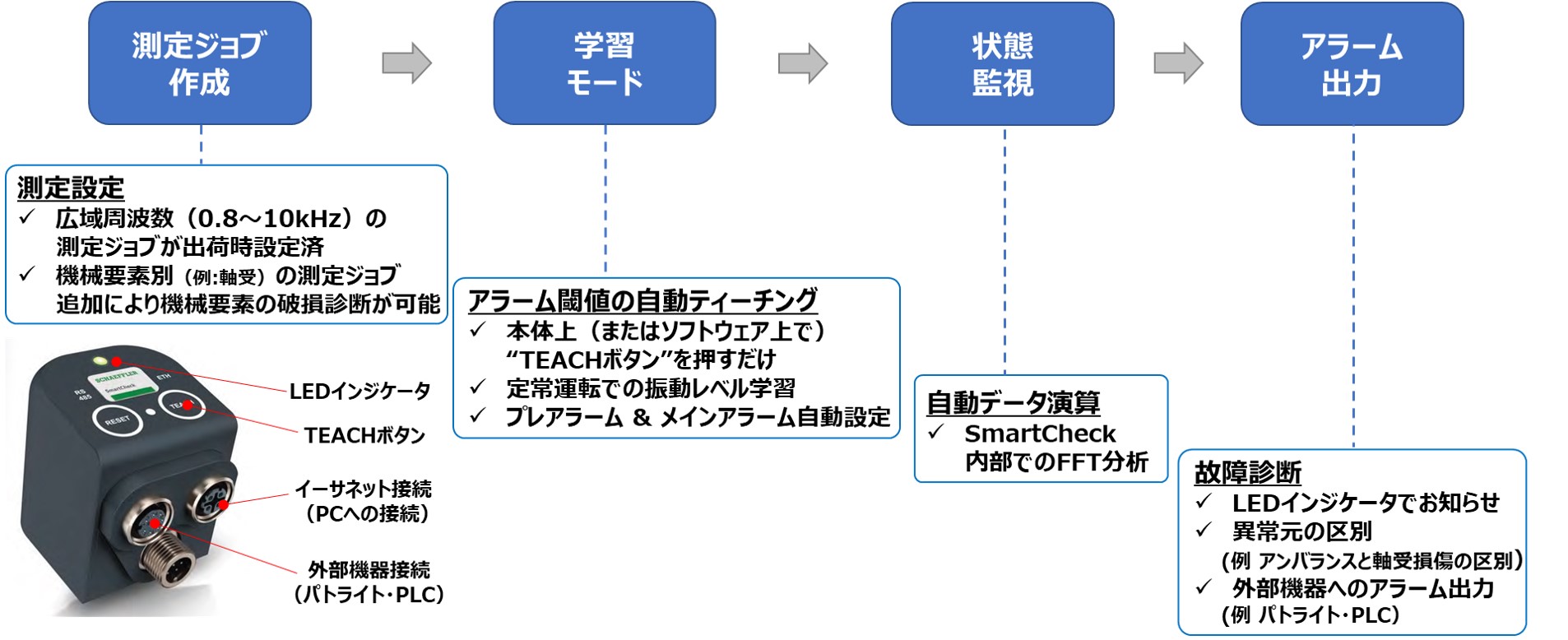

Measurement and Monitoring Flow

General-purpose measurement settings such as vibration acceleration measurement of 0.8~10kHz are preset. By simply pressing the “Learning Mode” button, the steady state of the equipment is automatically taught, and even the alarm threshold is set, and condition monitoring can be started smoothly.

* The alarm threshold can be changed arbitrarily.

Vibration calculations and analysis processes such as FFT are automatically performed inside SmartCheck, so there is no need for the user to perform a separate vibration analysis.

If the set threshold is exceeded, an alarm is triggered in two stages: a pre-alarm and a main alarm.

Alarm signals can be output to external devices (patrol lights or PLCs).

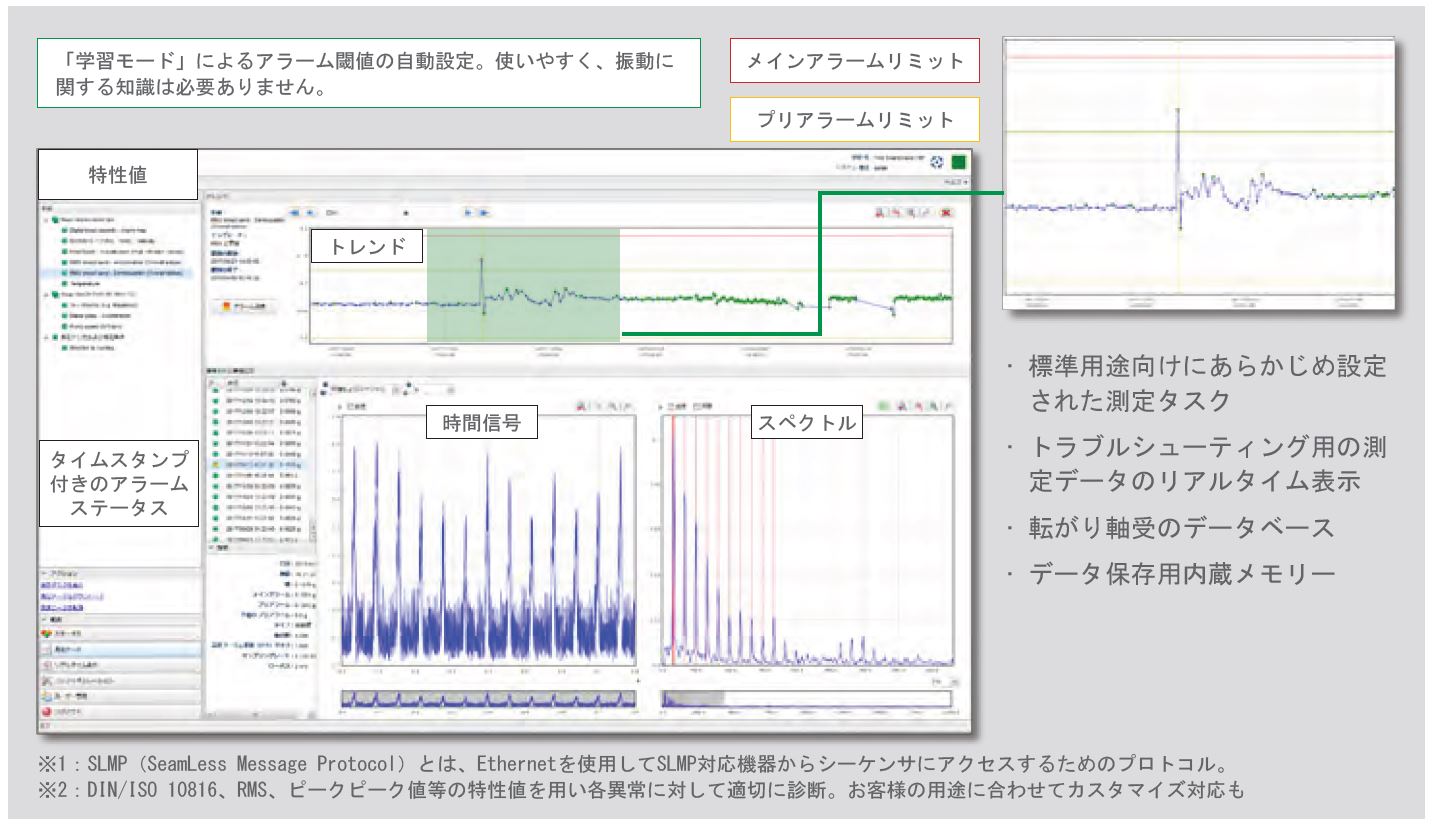

SmartWeb Trend Management Software

SmartWeb is a software for trend management, measurement settings, etc. It comes standard with SmartCheck and can be accessed via a web browser.

Anomaly detectable machine elements

Measurement templates are set up for different machines.

By detecting the natural vibration frequency of each machine element, including bearings, at the time of failure, it is possible to detect machine elements in which abnormalities have occurred.

- shipping

- gearbox

- fan

- Belt drive

- pump

- Rolling bearings

- Plain bearings

- shaft

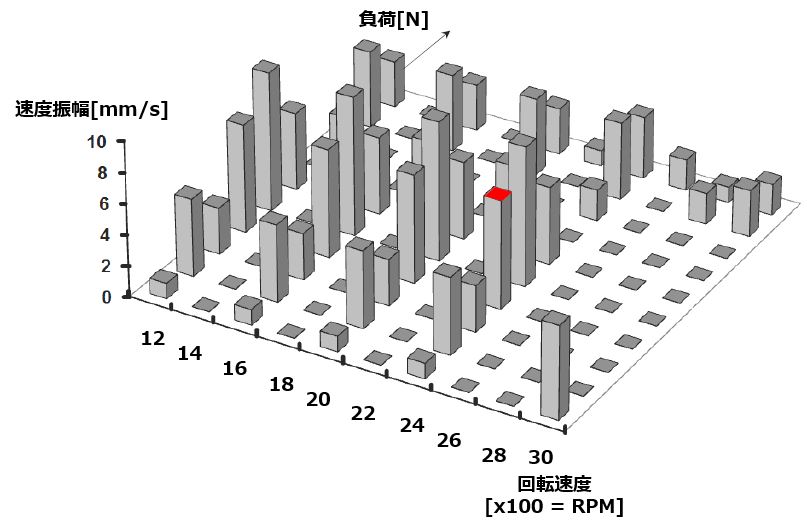

Alarm setting for variable speed and load fluctuations

Even when the operating speed or load fluctuates, the speed and load signals are input into SmartCheck to set the alarm threshold according to the respective operating conditions.

Example: When the speed and motor load (current) fluctuate

- Divide the speed region in 10 steps

- Performs a learning mode for each speed step and automatically sets thresholds

- When the two types of operating conditions (speed and load) fluctuate, thresholds are automatically set for a total of 100 operating conditions (10 steps of speed × 10 steps of load)

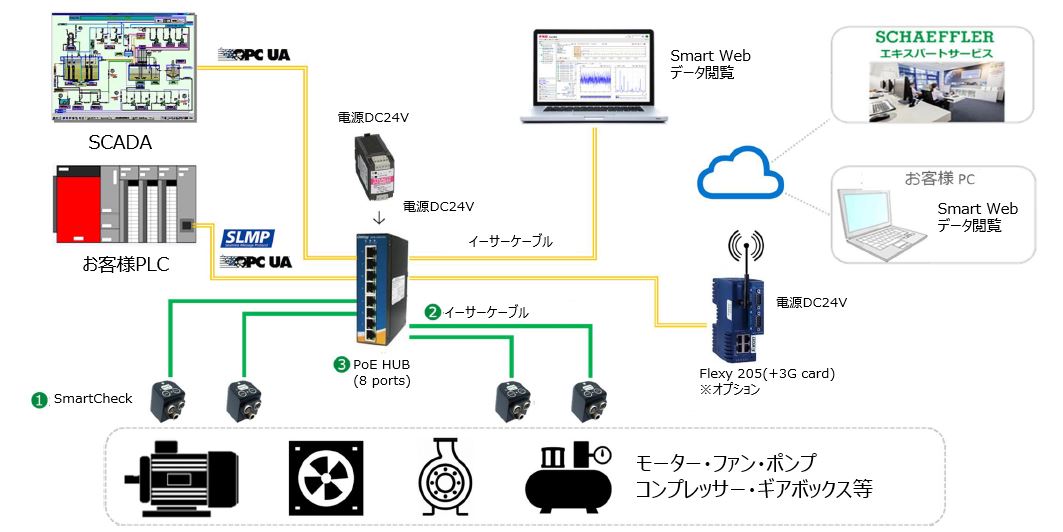

Facility monitoring Network connection example

specification

| measurement | Detection target | Vibration & Temperature |

| Frequency measurement range | 0.8 Hz ~ 10 kHz | |

| Temperature sensor measuring range | -20 ℃ ~ +70 ℃ | |

| sensor | Internal Specifications | 1-axis acceleration piezo sensor + temperature sensor |

| Operating temperature range | -20 ℃ ~ +70 ℃ | |

| Degree of protection | IP67 | |

| Body Dimensions | 44mm × 57mm × 55mm | |

| Mounting method | 4 Mounting Methods (1) Screwing (2) Magnet (3) Tapered Adapter (4) Adhesive | |

| other | power | DC 16-32 V or Power over Ethernet (PoE) |

| Communication Protocols | SLMP OPC-UA |

Related Products

-

Nakatani Kikai NG150A‐DRG Disc Grinder (Straight)

-

UHT Corporation Grip Assy For Outer Grinding Motor

-

Vessel No.TA20BSQ4L “GO-TAN” (Hard Forged) Mirror Socket Adapter (1/2″SQ 12.7mm Long)

-

Eight Tool 21TB-S7 Socket Bit

-

KONAN MAGSTER ⅡF AVPE1-08 5 Port Air Operated Valves Gasket-connected 3 Positions Center Open To PressureType

-

Vessel No.GT-PLHII Air Screwdriver Clutch Type