Nachi

Nachi GMS100 Skiving Machining Center For Gears

Manufacturer: Nachi-fujikoshi corp

Model: GMS100

Outline

Integrated process machine for small parts of electronics. EV. reduction gear. air craft. and medical instrument.

Gear machining processes (skiving. hobbing. lathe. drilling) are integrated into one machine.

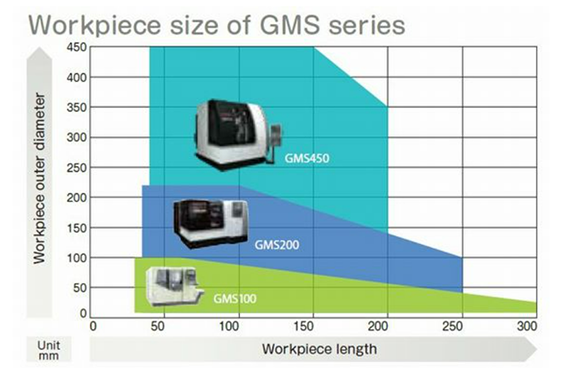

Optimal capability for small workpiece. (outer diameter: up to φ100mm. full length: up to 300mm)

Enhanced lathe function with optimal axis composition. special cutting tool. and program.

Installation floor space comparison: 54%-reduced with machining line of lathe. drilling and gear cutting.

High accurate machining for free curved surface is possible with high rigidity and by multi-axis synchronizing control.

Features

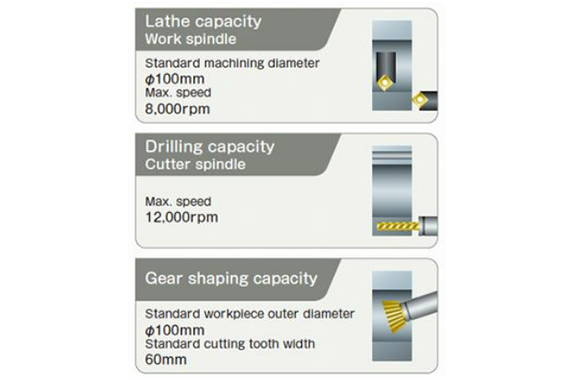

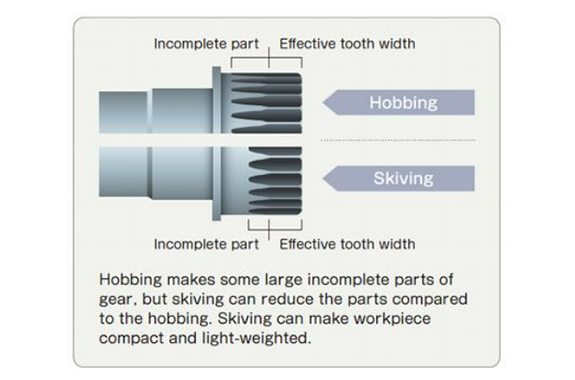

Machining capacity Comparison between skiving and hobbing

Comparison between skiving and hobbing

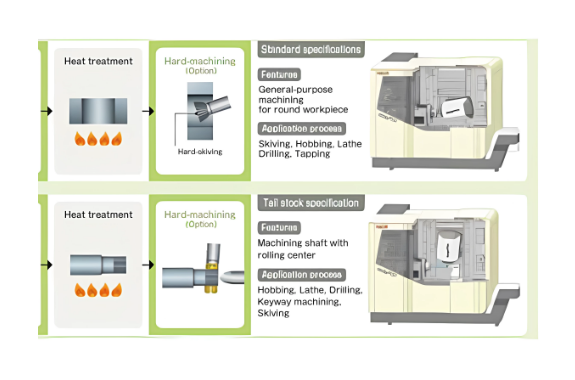

Suggestion of Integrated processes

Suggestion of Integrated processes

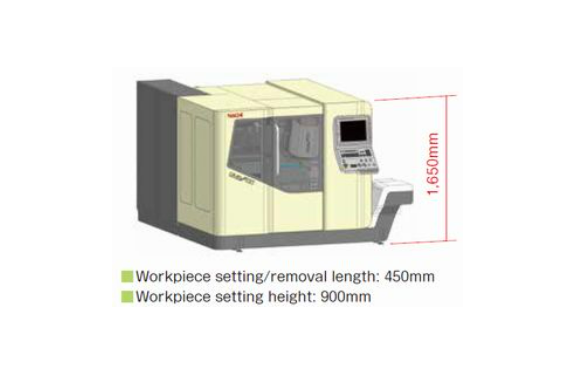

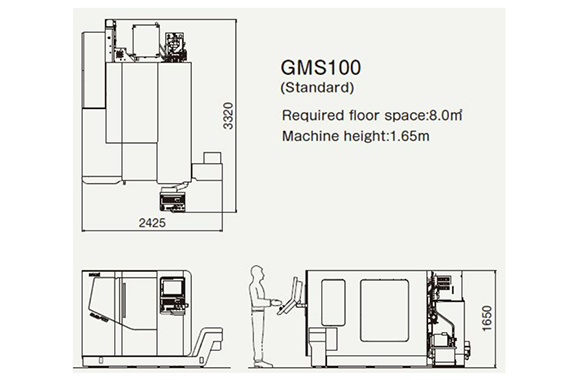

Reduced machine height and compact machine

Reduced machine height and compact machine

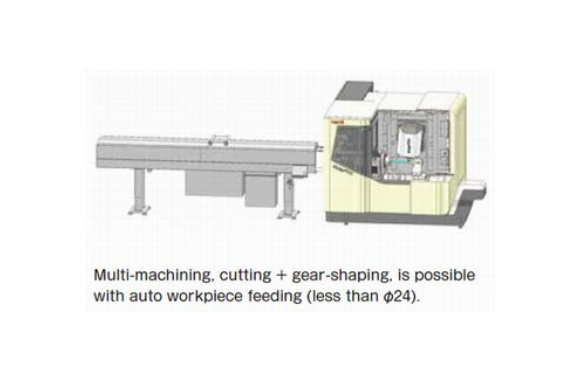

Bar feeder specifications

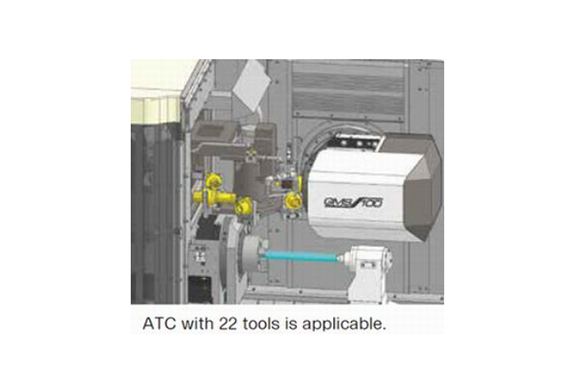

ATC specifications(6 tools)

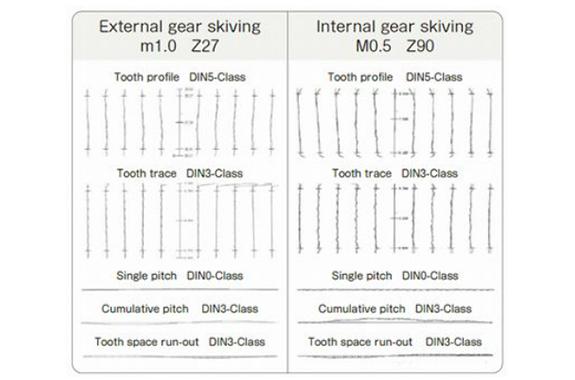

Machining example

Machining example

Simple gear shaping setting by interactive operation screen

Specification

Machining capacity | Workpiece diameter | Ø3 – 100mm (Internal skiving Ø40 – 100) |

| Max. workpiece length | 30 – 300mm (End-face machining; up to 60mm) | |

Cutter spindle | Spindle taper hole | Capto C6 |

| Max. RPM of spindle | 12,000rpm | |

Workpiece spindle | Max. RPM of spindle | 8,000rpm |

Each unit traverse (5 axes) | Z-Y-Z (back-forth/up-down/left-right) | X200mm / Y320mm / Z350mm |

| Tool swivel angle | -5 – 95 deg | |

| ATC (option) | Number of ATC tool storage | None / 6 / 22 |

| NC device | type | FANUC 31i-B |

Machine size (standard) | Main Body (width × length) | 2,425 × 3,320mm |

| Machine weight | about 6,500kg |

Layout diagram

Product line-up for ring gear machining

GMS100 Main specification