Japan, Kanetec, Lifting

Kanetec LPH Large Permanent Magnetic Lifma

Products Made in Japan

Manufacturer: Kanetec

Model: LPH

Permanent magnetic Lifma with smooth operation and enhanced safety realized by pursuing the optimum magnetic circuit to the limit.

Application

Permanent magnetic type lifting magnets used as a lifting section of cranes and hoists for transportation of steel materials in warehouses and machining shops or for loading and unloading workpieces to and from machine tools.

These are suitable for transporting semi-finished products having a flat surface such as machine parts, press dies and plastic molds and for transporting mill scale steel plates and flat steel materials.

Features

- All types are capable of lifting steel plates and round steel bars.

- The ON/OFF handle operating force has been reduced to a half max. of that of the conventional models. The operability in lifting thin workpieces and pipes that are difficult to lift with conventional models has been improved. (Patented)

- In addition to the conventional handle lock mechanism, a safety stopper is provided as a standard accessory. These double safety measures prevent falling of lifted objects due to unexpected returning of the handle. (Design registered)

- These are of permanent magnetic type requiring no power source. Thus, there is no risk of falling workpieces due to power failure or failure of wiring systems.

Precautions for use

When you plan to use the Lifma for special steel materials such as hardened materials, please consult with us prior to purchasing the Lifma.

The permanent magnetic Lifma LPH Series are not of waterproof construction. Ensure no water will enter or adhere to them.

Rust and scratches on the attractive face affect the holding power adversely. Repair it periodically.

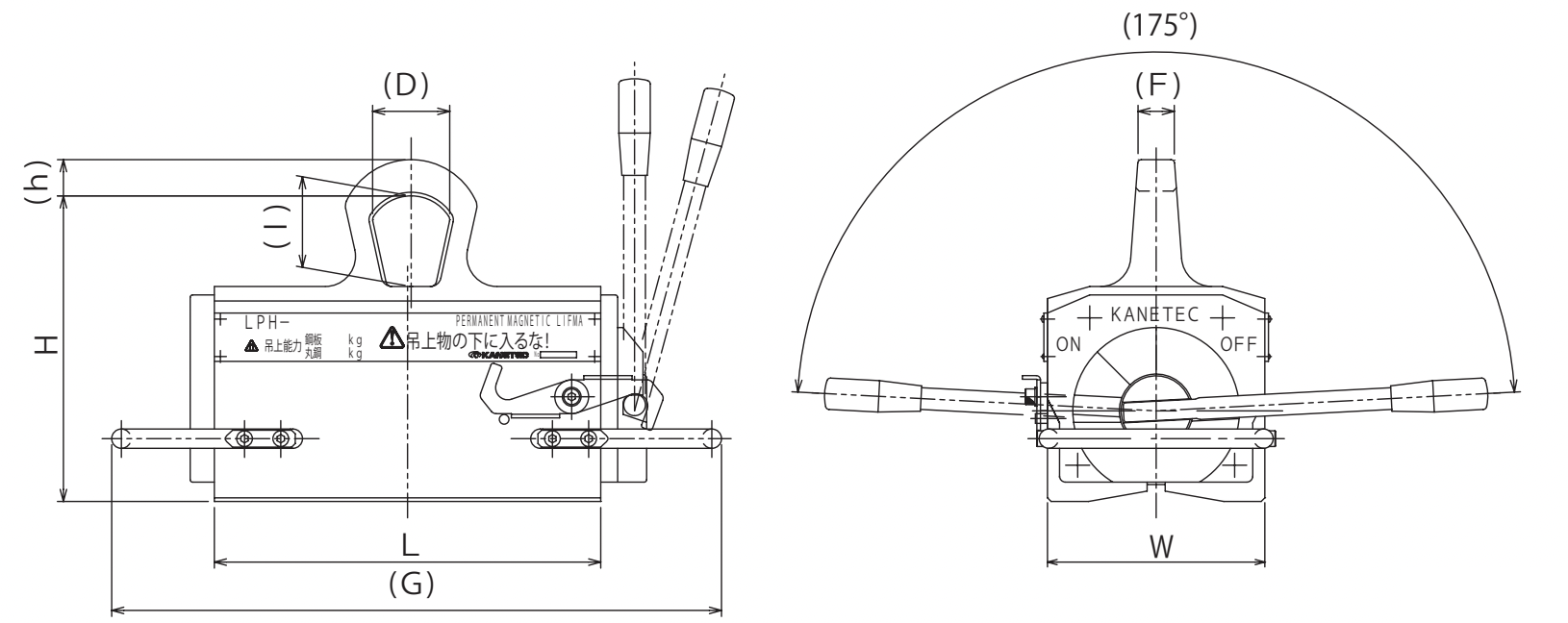

| Model | Lifting Capacity | Dimensions | Mass | ||||||||

| Steel Plate | Steel bar | W | L | G | h | H | D | I | F | ||

| LPH-1000 | 1000kg/ 2205 lb | 600kg/ 1323 lb | 180 (7.08) | 320 (12.5) | 320 (12.5) | 505 (19.8) | 30 (1.18) | 65 (2.55) | 75 (2.95) | 30 (1.18) | 80kg/ 176 lb |

| LPH-1500 | 1500kg/ 3307 lb | 800kg/ 1764 lb | 400 (15.7) | 400 (15.7) | 585 (23.0) | 35 (1.37) | 75 (2.95) | 85 (3.34) | 100kg/ 220 lb | ||

| LPH-2000 | 2000kg/ 4410 lb | 900kg/ 1984 lb | 205 (8.07) | 500 (19.6) | 500 (19.6) | 685 (26.9) | 38 (1.49) | 80 (3.14) | 97 (3.81) | 35 (1.37) | 130kg/ 286 lb |

※The lifting capacity is indicated by a value that is a third (safety factor 3) of the max. holding power.

Lifting standards

Steel plate lifting standard (Flat steel plates)

Thickness | Model (LPH) | ||

| 1000 | 1500 | 2000 | |

| t6 | 1300 (51.1) 1500 (59.0) x 1100 (43.3) | _ | _ |

| t12 | 1400 (55.1) 1500 (59.0) x 1300 (51.1) | 1450 (57.0) 1500 (59.0) x 1400 (55.1) | _ |

| t25 | 1350 (53.1) 1500 (59.0) x 1200 (47.2) | 1550 (61.0) 1500 (59.0) x 1600 (62.9) | 1750 (68.8) 1800 (70.8) x 1700 (66.9) |

| t50 | 1300 (51.1) 1500 (59.0) x 1100 (43.3) | ||

| t100 | 1000 (39.4) 1500 (59.0) x 650 (25.5) | 1100 (43.3) 1500 (59.0) x 800 (31.5) | 1300 (51.1) 1800 (70.8) X 950 (37.4) |

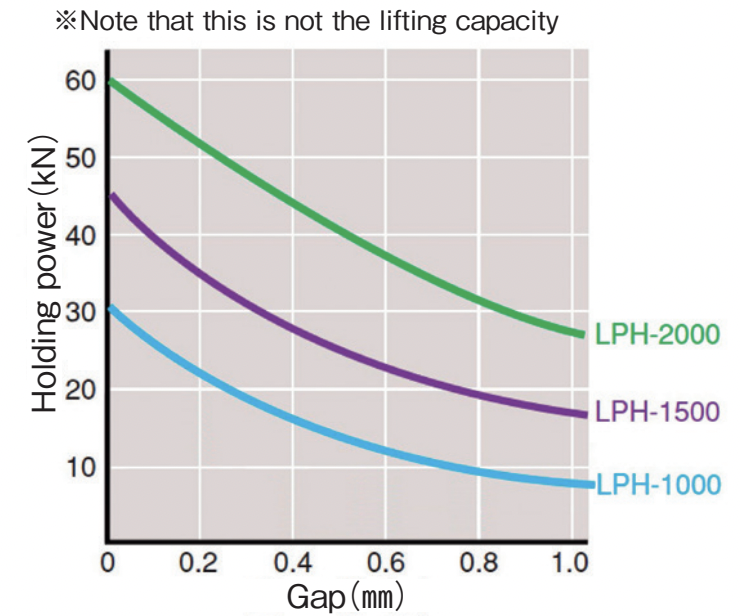

※If plates are thinner, the handle operation becomes harder. The handle operation also becomes harder when there is clearance. The return of the handle at the time of OFF operation becomes faster.

Round steel bar lifting standard (Mill scale)

Steel bar | Model (LPH) | ||

| 1000 | 1500 | 2000 | |

| Min. dia | φ1100 (3.93) x 3000 (118.1) L | φ1100 (3.93) x 3000 (118.1)L | φ1150 (5.90) x 3000 (118.1) L |

| Max. dia | φ1500 (19.6) x 300 11.8) L | φ1500 (19.6) x 400 15.7) L | φ1500 (19.6) x 450 17.7)L |

| Pipe allowable dia.※ | φ1100 (3.93)-700 (27.5) | φ1100 (3.93)-700 (27.5) | φ1150 (5.90)-700 (27.5) |

- The capacity varies depending on the wall thickness of pipes. If pipes are oval or curved, lifting them, even if they are short, is risky.In the case of pipes, the handle operation is harder than when handling steel plates.

- In the case of pipes of thin wall thickness, the handle operation becomes difficult. The return of the handle at the time of OFF operation becomes faster.

- The lifting capacity varies depending on the diameters of round steel bars. When workpieces are longer than 3 m, it is very dangerous to lift them with one unit of the Lifma since they cannot be held in balance. For long workpieces, consider the use of several beams.

※Keep in mind that the capacity drops when lifting pipes or workpieces the max. diameter of which is smaller than the attractive face or workpieces the max. diameter of which is shorter than the lifting standard length (LPH2000).

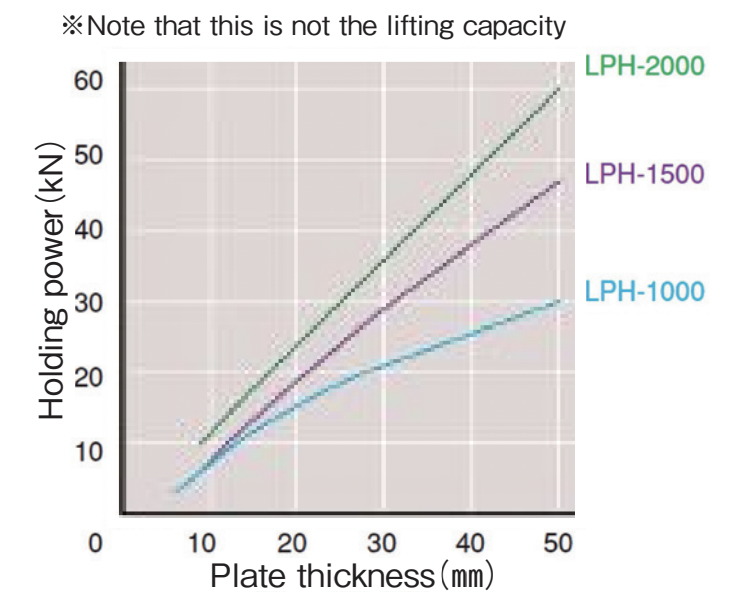

Relation between steel plate length and holding power (Material ss400.surface roughness▽▽ )

Relation between gaps and holding power (Material ss400.thickness50mm,surface roughness▽▽ )

Kouei is Distributor/Agent of Kanetec.

Other items of Kanetec

Request the quotation for Kanetec