Cutting, Japan, Nissan Tanaka

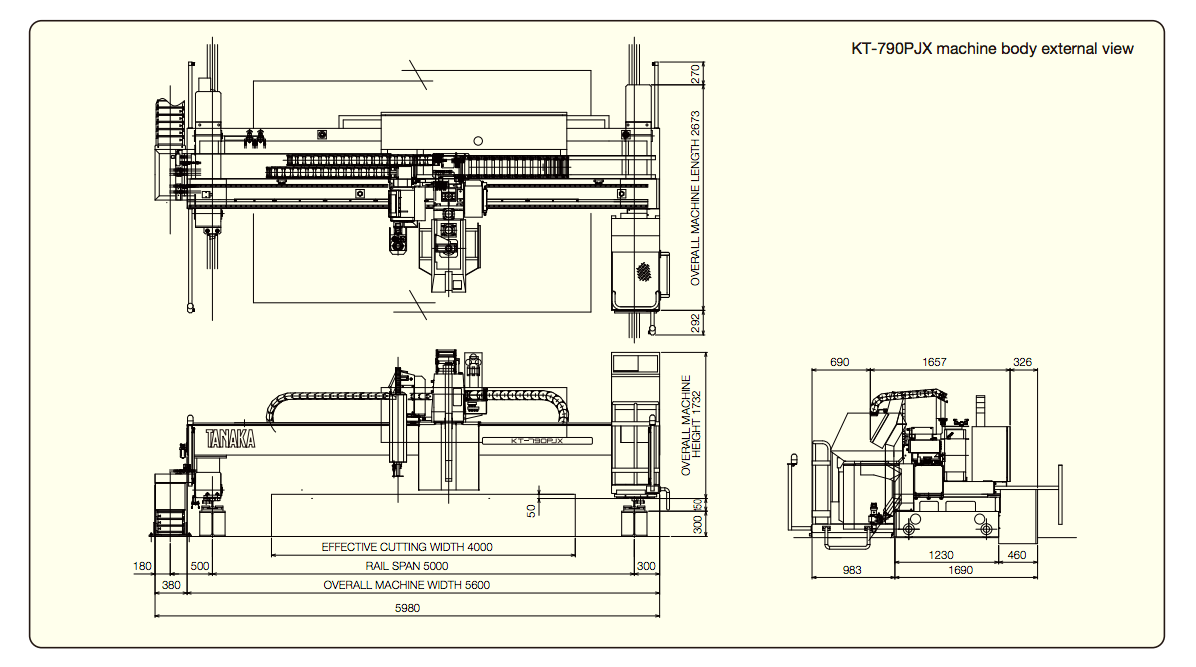

NISSAN TANAKA KT-790PJX Plasma Bevel Cutting Machine

Manufacturer: Nissan Tanaka

Model: KT-790PJX

High productivity brought out at cutting shops !

The KT-790PMX, which has gained a good reputation for its high-quality beveling and cost savings through a fast plasma-cutting process, has passed on its outstanding features to the KT-790PJX. The KT-790PJX has achieved even greater workability to meet the demands of cutting shops. By utilizing a newly developed Beveling Unit and reducing its size, the KT-790PJX has significantly lowered its cost and will undoubtedly offer high productivity to the international market.

KT-790PJX, that has pursued farther high speed process, high-quality, high efficiency.

- New bevel cutting unit: newly developed RA (Rotate/Angle) style bevel cutting unit, which is lighter/smaller/higher-rigid than conventional High Speed Link Style and TCL Style, is employed to improve not only movement speed, but maintainability as well.

- Improved operability: PCNC (FANUC FS311B+Panel i) is adopted to enhance Drawing Function. Real-time Drawing Function that shows you the current cutting-position and total cutting time while running a program, Document Viewer Function that can see Manuals on the screen, these two functions have been available on the machine.

- Improved cutting quality Newly developed Cut-condition Setting Function utilizing functions of PCNC enables you to set Cutting Conditions (AC current/Flow rate/etc) through NC controller. You can select Cutting material, Material thickness, Type of corner rope through NC controller, and the cutting can be done with much more suitable conditions.

KT-790PIX Main specifications

| Model | KT-790PJX |

|---|---|

| Rail span | 4,000~6,500mm |

| Effective cutting width | Rail span – 1,000mm |

| Rail length | Up to 50,000mm (Without cable-bearer less friction device) Up to 100,000mm (With cable-bearer less friction device) |

| Effective cutting length | Rail length – 3,000mm |

| Rail/rack size | 37kg/m rail (CP6)/50kg/m rail (CP6, CP10 and CP16) |

| NC controller | FANUC 311B+Panel i |

| Speed specification | Cutting speed: 0~10,000mm/min Rapid speed: 30,000mm/min Manual rapid speed: 12,000mm/min Cutting head lift up/down speed: 18,000mm/min |

| Plasma cutting apparatus | PEGASUS 500 or HPR-400XD (HYPERTHERM INC) |

Standard functions

Bevel cutting unit (RA style)

Initial height controller

Cutting height controller (Arc height control style)

Coordinate rotation function

Scheduled operation function

Operator’ s deck Area sensor

Optional functions

Stainless steel cutting

R-chamfering function (Only for PEGASUS 500)

Bottom 40 degree beveling function (Only for PEGASUS 500)

Powder marking device

Ink-jet marking device

Positioning camera

Dust collector (Stand-alone type)

Caution

The person who operates Plasma Cutting Machine shall be required to take an adequate training based on regulations/laws/etc of each country.

Be sure to read through “Instruction Manual beforehand, to properly operate the machine.

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka

Related Products

-

IKURATOOLS ISK-MP15F Mini Electro-hydraulic Double-acting Puncher

-

Vessel No.GT-P6T Air Impact Wrench, Torque Control Type

-

BIX B-35BRM/B-35BPM/B-35BSM Socket Bits

-

Vessel No.C51 Impact Driver Bit

-

KONAN 453S/453D Series 5-Port Solenoid Valves Pressure-resistant Packing Return Type

-

Eagle Jack (Konno Corporation) GW-60 Hydraulic Claw Jack