- Home

- Products

- Matsuda Seiki Rolls For Steelmaking Polishing of Large Rolls With a Film Polishing Machine

Japan, Matsuda Seiki

Matsuda Seiki Rolls For Steelmaking Polishing of Large Rolls With a Film Polishing Machine

Product: Made in Japan

Manufacturer: Matsuda Seiki

Model: Rolls For Steelmaking

Alternative polishing techniques have emerged as a significant advancement in surface finishing, offering considerable time savings and improved outcomes compared to traditional methods. Among these, “film polishing” stands out for its ability to achieve an excellent finished surface rapidly. This method also greatly reduces the likelihood of polishing unevenness and scratches, marking a notable improvement over conventional techniques.

For instance, a roll manufacturer in the steel industry faced challenges with removing feed marks left by whetstone polishing on large rolls. Before adopting new technology, the machining time stood at an extensive 9 hours per piece. However, the introduction of the “Super Finisher” technology marked a turning point. Remarkably, after its implementation, the process required just 30 minutes per pass, with a total of 4 passes, culminating in a dramatically reduced machining time of 2 hours per piece.

This transition signifies a monumental reduction in processing time to less than a quarter of the original duration. Consequently, the adoption of film polishing and similar advanced techniques represents a pivotal shift in the industry, enabling manufacturers to achieve superior surface finishes more efficiently and effectively.

Processing example

■Customer: Steel roll manufacturer

■Workpiece material: Tungsten spraying

■Workpiece size: φ350 x 3000

■Product name: Bridle roll

■Purpose: Removal of feed marks from grinding stone

■Required surface roughness: R max 0.3μm /Ra 0.04μm

■Processing time before installing Super Finisher: 9H/1 piece

■ Processing time after installing Super Finisher: 30 minutes (1 pass) x 4 passes = 2H/1 piece *Test processing is available.

Basic information

Features of film polishing

■ Achieves an excellent finished surface in a short period of time

■ It is possible to minimize unevenness in polishing and the occurrence of scratches

Related Products

-

Mikasa FU-162A FV-302 High Frequency Inverter

-

292 Swivel Scaffoding Clamp

-

Eagle Jack (Konno Corporation) ED-100TC-PG-75H-100 Hydraulic Bottle Jack

-

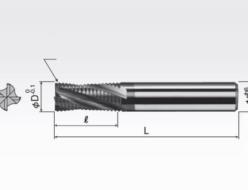

Okazaki Seiko SPSRC4A Coated Solid Carbide Roughing Endmills (4 Flutes)

-

NAC – SP TYPE Stainless steel (SUS304) Socket Quick Couplings

-

Fujii Denko R-560-N-PT Harness & Lanyard