- Home

- Products

- Chiyoda Seiki Gas Saver/Pressure Regulator With Dial Type Flow Meter Econo Dial Series H Type Econo Cube EC-R Type For Piping (With Adjuster)

Chiyoda Seiki, Japan

Chiyoda Seiki Gas Saver/Pressure Regulator With Dial Type Flow Meter Econo Dial Series H Type Econo Cube EC-R Type For Piping (With Adjuster)

Made in Japan

Manufacturer: Chiyoda Seiki

Feature:

●Employs a balanced structure that does not cause secondary pressure fluctuations even if the pressure inside the container drops.

●Pressure regulator It is economical due to the adoption of a unique structure that uses as little gas as possible.

●Different from the float-type flowmeter, the dial-type flowmeter can accurately return the flow rate even if the length of the hose is different.

Dial-type flow meter

● The mounting angle can be freely selected because the flow rate does not vary depending on the mounting angle.

● The easy-to-read scale allows you to accurately match the flow set to the welding conditions.

Gas Saver (Econoflow)

● Easy operation! Just turn the handle left and right.

●Since it is possible to supply a stable flow rate from the start of contacting, the arc start is improved.

●It is rational and economical because there is no individual difference in gas consumption depending on the worker’s bag.

Specifications

Reasons for Saving Operation Principle of Gas Saver (Econoflo)

In conventional regulators with float type flow meters, the flow rate is regulated by the flow meter valve. When gas is flowing, the opening of the valve creates a differential pressure, and the pressure downstream of the valve is lower than the pressure upstream. However, even at the stage when the outlet side is closed and the gas flow is stopped, the valve itself remains “open” in the operating state, and the flow path remains as it is. As a result, the pressure inside the gas hose rises to the pressure gauge at the outlet of the regulator. This phenomenon occurs because the valve itself of the conventional float type flowmeter does not have the function to close the flow path. vinegar.

* Econoflow is a valve with a pressure adjustment function. In the case of Econoflow, the adjustment handle is used to set the flow rate of the dial-type flow meter. , when the gas stops, the inner diaphragm automatically rises to function as a stop valve and block the flow path, maintaining the adjusted working pressure, so the secondary pressure (internal pressure of the hose) rises. I don’t. as a result…

Low pressure in hose.=The amount of gas remaining in the hose is small.=Less wasteful gas is emitted at the start.

=> Waste gas is greatly reduced in total, and shield gas cost can be greatly reduced.

Related Products

-

Daitoukeiki WA12B type guage WA Enclosed Guages(Metal)

-

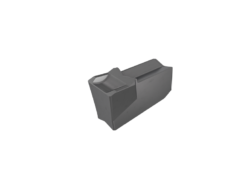

SAKUSAKU DIMC4 6L Insert For Grooving / Parting Off With C-type Chip Breaker

-

U_RD CTU-8-CLS-CV50 Data conversion equipment

-

NISSAN TANAKA 166S Number.03 Welding Torch

-

SAKUSAKU SAK D190S25-2D Indexable Drill

-

NAGANO KEIKI KE21 Pneumatic Transmitters Pressure