Chemical, Isolite Insulating, Japan

Isolite Insulating Isowool BSSR Block

Manufacturer: Isolite Insulating

RCF FREE:Modules of Alkaline Earth Silicate(AES) Wool

Features

Modules processed by Alkaline Earth Silicate(AES) Wool

ISOWOOL BSSR UNIBLOK (edge-stacked) and SABER BLOC (folded) are prefabricated modules, manufactured from Alkaline Earth Silicate (AES) Wool. BLANKETs are edge-stacked or folded to achieve high density and greatly reduce thermal conductivity.

Specifically designed to enable efficient installation for most lining applications.

Module Types

| Module Types | Anchor Type | |

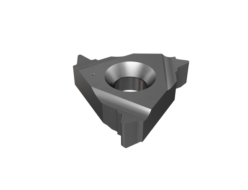

| UNIBLOK | Module made of cut and tightly compressed BLANKETs | M, T |

| SABER BLOC | Accordion-like module made of a folded and layer compressed BLANKET | M, T |

| D BLOCK | Module made of cut and sewn BLANKETs | B, S1 |

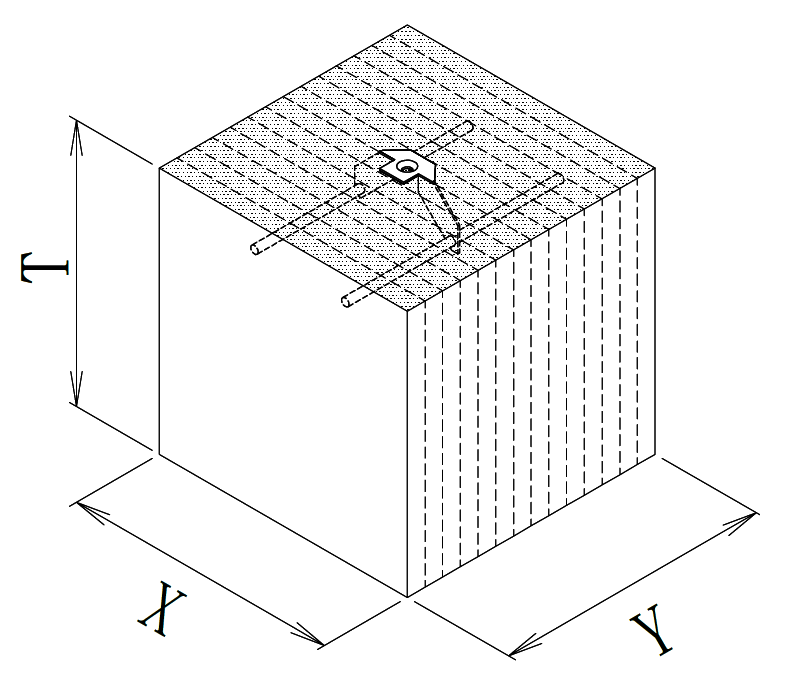

Dimensions Guide:

T: thickness X: width Y: stacking direction

(T) mm ⅹ (X) mm ⅹ (Y) mm

・Custom shapes require a drawing.

Anchoring System

For UNIBLOK and SABER BLOCK

TYPE-S:Stud-bolt is welded to the shell. Module is inserted and fixed to the anchoring system with a nut and washer.

TYPE-M:Anchoring system is incorporated into the module. Module is fixed to the stud-bolt with a special nut from the inner face of the furnace.

TYPE-T:Anchoring system is incorporated into the module. Module is fixed by attaching a nut from the outer face of the furnace.

For D BLOCK

TYPE-B:Anchoring system is incorporated into the module. Module is fixed to the special stud-bolt by fastening a special nut from the inner face of the furnace.

TYPE-S1:Anchoring system is incorporated into the module. Module is fixed by attaching a nut and washer from the outer face of the furnace.

Typical Application

- Inner lining insulation for industrial furnaces (Industries: Steel, Non-Ferrous Metals, Glass, Ceramics, Petrochemicals, Cement, etc.)

- Ladle lid inner insulation

【Note】

Isowool BSSR products are subject to rapid changes in volume (shrinkage) due to their thermal history and chemical composition.

When making an inquiry, please describe your operating conditions and other relevant information.

Quality

| Product Name | BSSR 1300 UNIBLOK | BSSR 1300 SABER BLOC | BSSR 1300D BLOCK | BSSR 1400 UNIBLOK | BSSR 1400 SABER BLOC | |

| Temperature Grade (°C) | 1300 | 1300 | 1300 | 1400 | 1400 | |

| Bulk Density (kg/m³) | 160 | 130 | 130 | 160 | 160 | |

| Thermal Conductivity W/(m・K)) JIS A 1412-1 *Calculation value | at 400°C | 0.11 | 0.11 | 0.11 | 0.13 | 0.13 |

| at 600°C | 0.19 | 0.19 | 0.19 | 0.22 | 0.22 | |

| at 800°C* | 0.33 | 0.33 | 0.33 | 0.34 | 0.34 | |

| Linear Shrinkage (%) | at 1200°C×24h | 2.2 | 2.2 | 2.2 | – | – |

| at 1300°C×24h | – | – | – | 1.9 | 1.9 | |

| Chemical Composition (%) | SiO₂ | 77 | 77 | 77 | 77 | 77 |

| CaO+MgO | 20 | 20 | 20 | 19 | 19 | |

| Others | 3 | 3 | 3 | 4 | 4 | |

Standard Size (mm)

| Bulk Density (kg/㎥) | Thickness | Width | Length | |

| BSSR 1300 UNIBLOK SABER BLOC, HS BLOK | 160 | 100~300 | 300 | 300 |

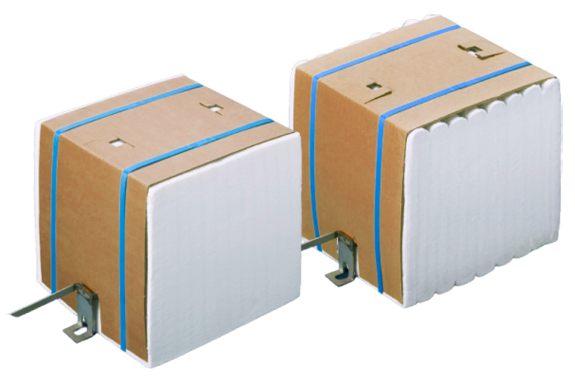

Packaging

| Size(mm) | Pcs per carton | Carton box | ||

| Thickness | Width | Length | Size(mm) | |

| 100 | 300 | 300 | 6 | 620X335X335 |

| 200 | 3 | |||

| 300 | 2 | |||