Japan, UHT CORPORATION

UHT Corporation CCS-710 Series Ceramics Casting System Machine

Made in Japan

Manufacturer: UHT CORPORATION

Model: CCS-710 Series

New casting system by integrating the process from coating to drying in a compacted manner

A flexible condition setting can be set with touch panel.

Coating thickness: 5 to 200μm Coating width: Max.250mm Drying temperature: Max.150℃ Speed: 200 to 12,000mm/min.

Easy setting

Characteristics

Flexible condition setting

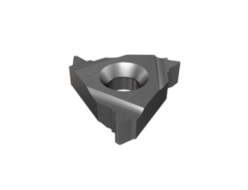

Adjustable and fixed-type casting head blades are prepared.(OP.)

Adjustable type casting head blade can flexibly set coating thickness. You can easily exchange the installation of adjustable and fixed type casting head blades.

The condition during coating can be set.

Coating conditions (temperature, amount of blow, feed speed and tension) can be set at one location.

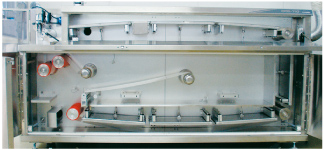

Minute control of drying condition

The amount of ventilation and the temperature of the seven table heaters can be individually controlled.

Inspection of slurry coating

The Backlight stage allows an easy check of the state of coated condition of the slurry.

Easy cleaning and film exchange

Easy structure of cleaning and film exchange

Safety

Safety structure to separate coating section and the control board

Standard Specifications

| Model | CCS-710 | |

|---|---|---|

| Coating | Method | Doctor blade method used for coating on the film(Adjustable-type: option / Fixed-type: option) |

| Material | Ceramics slurry | |

| Width size | Max.250mm(Width of career tape:260mm) | |

| Thickness | 5~200μm(Depend on the slurry condition) | |

| Speed | 200~12,000mm/min | |

| Inspection | Backlight used for visual inspection of coating condition | |

| Supply of slurry | Tube pump used to supply slurry to the liquid dam.(Option) | |

| Film(roll) | The outer diameter of the unwinder | Max. 220mm in diameter |

| The outer diameter of the winder | Max. 300mm in diameter | |

| Weight | 25kg or less | |

| Installation shaft | φ3B(3B paper tube clamping) | |

| Dryness | Method | Table heater used to dry slurry from below the carrier tape |

| Temperature | Max.150℃ | |

| Zone/Length | 7 zone×500mm=3,500mm | |

| Air blow | Two fans are used to control the suction/exhaust amount to select optimal drying conditions (Air blow control up to 60℃ is possible for an option.) | |

| Carrier film | Film feed | Winding with the servo motor. Powder Blake is used to control tension for unwinding. |

| Meandering prevention | The unique mechanism was adopted to prevent the tape from meandering. | |

| Cleaning | An adhesive roll is used to clean both sides of the tape before coating. | |

| Control function | Control unit | Dedicated controller for mechanical control made by UHT (MJUC) |

| Operation | Operation with the 10.4-inch graphical touch panel | |

| Static eliminating unit | The static-eliminating bars are set up with 1 piece for each unwinding and winding side. | |

| Safety | Cover | Heat-insulated, sealed type |

| Structure | The operation panel is separated from the coating section and air purge is conducted for the equipment box to prevent solution gas from entering. | |

| Material and structure of housing | Stainless steel welded frame | |

| Air pressure source(for static eliminating) | Pressure | 0.2~0.5MPa(Clean air) |

| Connected diameter | Outer diameter φ12 tube | |

| Exhaust | Flowing quantity | Max 8.1m3/min |

| Duct connected diameter | Outer diameter φ73mm | |

| Power sourse | 3φ AC200V ±10% 5kVA | |

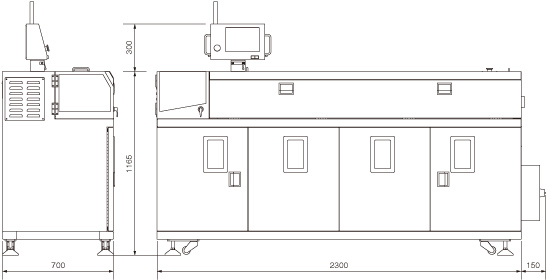

| Dimension | W2300(Breaker box+150mm)×D700×H1165mm(Operation panel+300mm) | |

| Weight | Approx.700kg | |

| Working condition | Temperature | 10~35℃(22±2℃ recommended) |

| Humidity | 40~60%(Non-dewing) | |

Options

- Casting head, blade

- Adjustment jig for adjustable casting head

- Pump that automatically supplies slurry

- Temperature adjustment heater for slurry

- Articles of consumption

Outline Drawing