IKURA SEIKI, Japan

IKURATOOLS ISK-CP13LS Portable Angle Processing Machine

Made in: Japan

Manufacturer: IKURA SEIKI

Model: ISK-CP13LS

Features

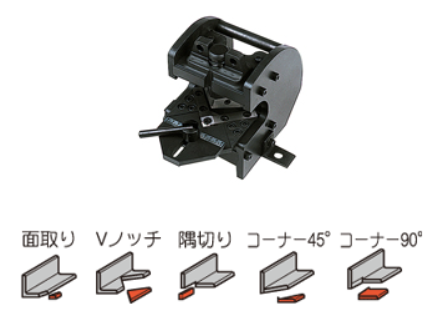

Attachment can be exchanged for a variety of angles.

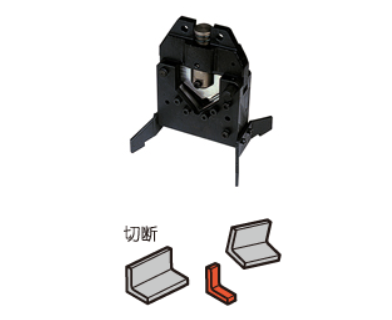

* The photo on the left is when the notcher attachment is attached.

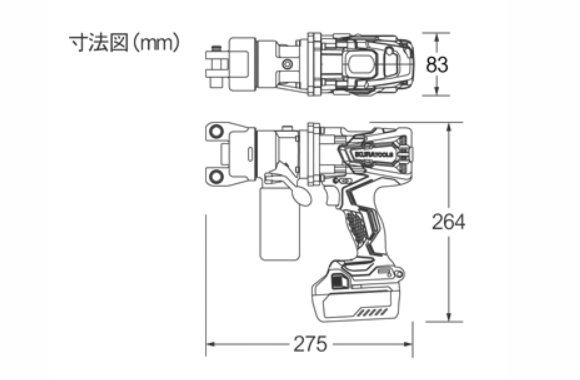

Specifications

| Specification | |

|---|---|

| Maximum processing pressure | 127kN(13ton) |

| Motor | DC36V |

| Power | Battery pack DC36V 2.5Ah (Li-ion) |

| ChargerAC100V 50/60Hz | |

| Charging time | 32 min. |

| Mass | 5.0kg (including battery pack) |

| Standard Accessories |

|---|

| Charger, 1 battery pack, hex wrench #6, carrying case (made of resin) |

Cutter Attachment IS-A50C

Specification

| Maximum processing capacity | Angle material SS400: L50×50×t6 |

| Angle material SUS304: L50×50×t4 | |

| Outer Diameter Dimensions | W162×L150×H246mm |

| Mass | 8.2kg |

Standard Accessories

Shredding material support, hex bar wrench #6

Notcher Attachment IS-A50VⅠ

Specification

| Maximum processing capacity | Angle material SS400: L50×50×t6 |

| Angle material SUS304: L50×50×t4 | |

| Outer Diameter Dimensions | W180×L245×H215mm |

| Mass | 16kg |

Standard Accessories

Fixing brackets, hexagonal wrench #5 and 6

Puncher Attachment IS-A14P

Specification

| Maximum processing capacity | Angle material SS400: Φ14 t6 |

| Angle material SUS304: Φ14 t4 | |

| Outer Diameter Dimensions | W100(190)×L207×H232mm |

| Mass | 4kg (including stand) |

Standard Accessories

Punch and die for round holes (L11B), stand, single-sided wrench #10, hex wrench #3

Puncher (IS-A14P) Replacement Blade Table

| For round holes (mm) | Φ6 | Φ8 | Φ10 | Φ11 | Φ12 | Φ13 | Φ14 | |||

| For slotted holes (mm) | 6.5×10 | 8.5×13 | 10×15 | 11×15 | ||||||

Vendor Attachments ISK-A50BⅡ

Specification

| Maximum processing capacity | Angle material SS400: L50×50×t6 |

| Angle material SUS304: L50×50×t4 | |

| Outer Diameter Dimensions | W132×L228(295)×H124mm |

| Mass | 7kg |

Standard Accessories

Hexagonal wrench #3 & 6

Battery Pack Lithium-ion battery LIB1840 Sold Separately

Charger LBC1814 Sold Separately

IKURA Genuine Hydraulic Operating Oil (ISO VG32) Sold separately

IKURA Genuine Hydraulic Acting Oil Sold separately

Further improving the performance of Ikura Seiki’s hydraulic products

It is a high-performance oil.

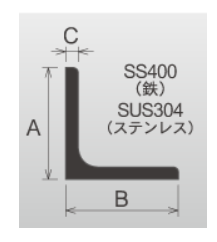

Reference Material: Angle Size (Equal Leg Angle Steel)

| SS400 Angle (Equilateral Angle Steel) | |||

|---|---|---|---|

| A×B×C | |||

| 25×25×t3 | 45×45×t4 | 50×50×t6 | 65×65×t6 |

| 30×30×t3 | 45×45×t5 | 60×60×t4 | 65×65×t8 |

| 40×40×t3 | 50×50×t4 | 60×60×t5 | 70×70×t6 |

| 40×40×t5 | 50×50×t5 | 65×65×t5 | 75×75×t6 |

| SUS304 Angle (Equilateral Angle Steel) | ||||

|---|---|---|---|---|

| A×B×C | ||||

| 20×20×t3 | 30×30×t4 | 40×40×t4 | 50×50×t5 | 65×65×t5 |

| 25×25×t3 | 30×30×t4 | 40×40×t4 | 50×50×t5 | 65×65×t6 |

| 25×25×t4 | 30×30×t6 | 40×40×t6 | 60×60×t5 | 70×70×t5 |

| 30×30×t3 | 40×40×t3 | 50×50×t4 | 60×60×t6 | 75×75×t6 |

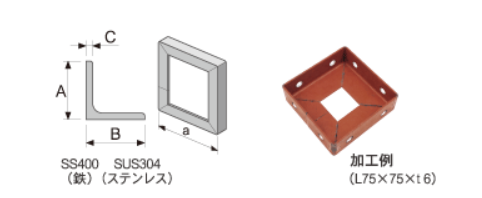

Reference Material: Minimum Required Dimensions for Formwork Construction

| Nominal dimensions of angle steel | Minimum Required A Dimensions | |

| A×B×C | ||

| 40mm×40mm×t3 | 110mm | |

| 40mm×40mm×t5 | 110mm | |

| 45mm×45mm×t4 | 110mm | |

| 45mm×45mm×t5 | 110mm | |

| 50mm×50mm×t4 | 110mm | |

| 50mm×50mm×t5 | 110mm | |

| 50mm×50mm×t6 | 110mm | |

| Nominal dimensions of angle steel | Minimum Required A Dimensions | |

| A×B×C | ||

| 60mm×60mm×t4 | 130mm | |

| 60mm×60mm×t5 | 130mm | |

| 65mm×65mm×t5 | 140mm | |

| 65mm×65mm×t6 | 140mm | |

| 70mm×70mm×t6 | 150mm | |

| 75mm×75mm×t6 | 160mm | |

| * The blue belt is Angle Master II and Angle Master Compact. | ||

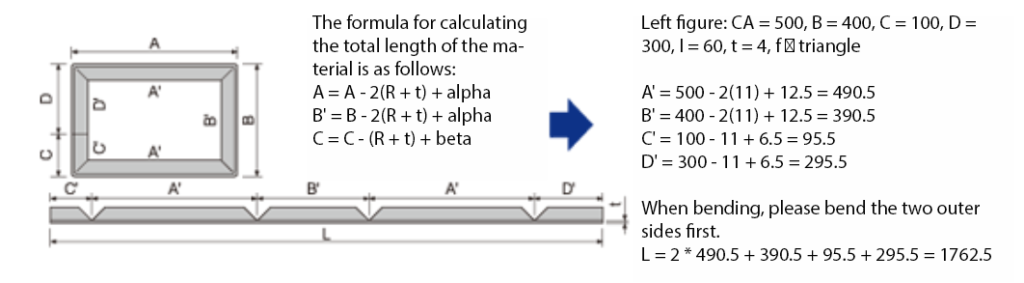

Reference Material: Tips for Processing

The dimensions of angle materials differ depending on the material and tensile strength, so please refer to the approximate table below.

| Plate thickness | Bending radius R | R+t | Bilateral bending constant α | One-sided bending constant α | |||

| 3t | 3 | 6 | 7 | 3.5 | |||

| 4t | 3 | 7 | 8 | 4 | |||

| 5t | 5 | 10 | 12 | 6 | |||

| 6t | 5 | 11 | 12.5 | 6.5 | |||