Japan, REX Industries Co.

REX Cutting tools Pipe Cutter Series

Product Made in Japan

Manufacturer: REX Industries Cp.

Model: Cutting tools

Mantis Saw Blades (Optional extras)

Be sure to use only the recommended blades.

Features

-High-speed Blades: Made of HSS Cobalt for durability, plasticity, and resistance to high temperatures. Suitable for stainless steel and other materials that are difficult to cut.

-Alloy blades: Suitable for common steel materials such as alloy tool steel, and special steel.

Note: Allow new blades to run in by making a few cuts first.

-Effect of running in the blade: If you use a new blade to suddenly cut a workpiece, it can result in the teeth getting chipped and intial wear.

Running in the blade can greatly affect its life span. It is particularly important in the case of pipe, shaped steel, small articles, etc.

-How to run in a new blade:

1. wipe off any oil or dirt before placing the blade in the unit.

2. Set the cutting load adjustment dial to L, and cut some material once or twice.

Running the machine for long periods of time without any material significantly shortens the life of saw blade.

Specifications

| Code No. | Material | No. of teeth(teeth/inch) | No. of blades included | |

| XB125 XB120A | 475302 | Alloy | 14 | 10 |

| 475303 | 18 | |||

| 475312* | HSS(Bimetal) | 14 | 5 | |

| 475313 | 18 | |||

| 475314 | 24 | |||

| XB180WS XB180WA | 475200 | Alloy | 8 | 10 |

| 475201 | 10 | |||

| 475202 | 14 | |||

| 475203 | 18 | |||

| 475204 | 24 | |||

| 475210 | HSS(Bimetal) | 10 | 5 | |

| 475211* | 14 | |||

| 475212 | 18 | |||

| 475213 | 24 | |||

| 475220 | Grid saw | – | ||

| 475270* | HSS(Bimetal) | 14 | 5 | |

| 475275 | 18 | 5 |

Standard accessory.

Selecting the cutting Load and Blade for XB-125/ 120A/ 180WS/ 180WA

Use the table below to select the blade and cutting load that are approprite for the type, diameter, wall thickness etc. of the material to be cut.

Specifications

| Material | Alloy Blade | High-speed steel Blade | Grid saw | ||||||||||

| tooth | 8 | 10 | 14 | 18 | 24 | 10 | 14 | 18 | 24 | ||||

| Steel pipe | Norminal size | 8A-25A(1/4”-1”) | L | L | L | ||||||||

| 32A-80A(1 1/4”-3”) | M | M | M | ||||||||||

| 90A-150A(31/2″-6″) | H | H | H | ||||||||||

| Stainless steel | Schedule 40 | 8A-25A(1/4”-1”) | L | L | |||||||||

| 32A-80A(1 1/4”-3”) | M | M | |||||||||||

| 90A-150A(31/2″-6″) | H | H | |||||||||||

| Thin wall stainless steel(SU pipe) | 13-125Su | LL | |||||||||||

| 150Su | LL | L*3 | |||||||||||

| Plastic pipe(Polythylene pipe/ Vinyl Chloride pipe) | LL | LL | LL | LL | |||||||||

| Conduit | Thick Steel | M | M | ||||||||||

| Thin Steel | LL | L | L | ||||||||||

| Cast iron pipe | H | H | |||||||||||

| Moster-lined cast-iron pipe | H | ||||||||||||

| Steel pipe | Section steel | Thickness | less than or equak 1.9mm | LL | |||||||||

| 2-3.4mm | L*1 | L*2 | L*1 | L*2 | |||||||||

| 3.5-4.9mm | M*1 | M | M | M | |||||||||

| 5-7.9mm | M | H | H | ||||||||||

| greater than or equal 8mm | H | H | H | ||||||||||

| Round bar | less than or equal 15mm | M*1 | M | M | M | ||||||||

| 16-50mm*4 | H | H | |||||||||||

| 51-80mm*1 | H | H | H | ||||||||||

LL=ultra-light load

L= light load

M=medium load

H=heavy load

Notes – The igures in the table are examples only. Select the blade and cutting load to match the actual material to be cut.

-When selecting the proper number of teeth on the table, use the following guideline: thickness of material = 2 teeth.

-Depending on their composition or hardness, some materials are not applicable to the above table.

-When cutting a plastuc pipe, even if LL(ultra-light load) is selected, the plastic pipe may be cut diagonally caused by heavy vutting load.

-To avoid such diagonal cutting, hold the handle of the frame with your hand and slowly lower the frame to cut it down.

*1 XB180W only

*2 XB125/120A:M

*3 XB125/120A:LL

*4 XB 125/120A : 16-60mm

Saw blade essentials

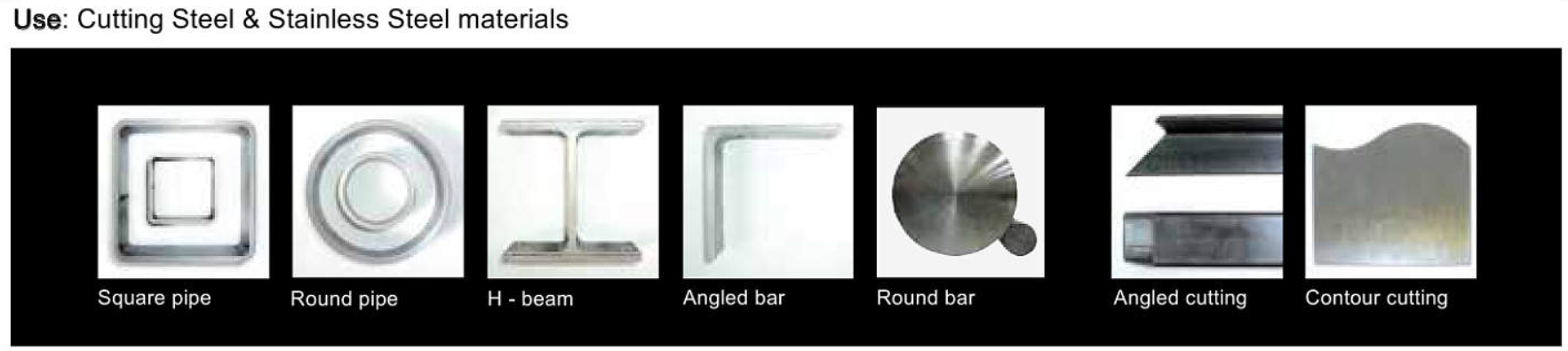

-Two types available

Alloy blade for steel pipe

HSS blade for stainless steel pipe

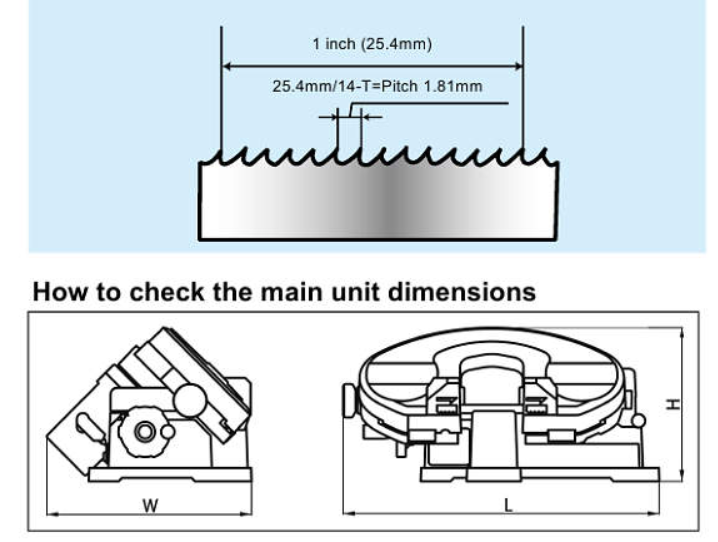

-What is the difference between the 14-tooth and the 18-tooth blade?

14-T: Provides a sharper, faster cut

18-T: More precise for right angles but slower than the 14-T

-What does”tooth”mean?

14-tooth means there are 14 teeth per inch(25.4mm). No. of notches to set the value lever at when cutting ( for XB270A)

No. of notches to set the value lever at when cutting ( for XB270A)

| Material | High-speed steel Blade | ||||

| 14 | 18 | ||||

| Value lever notches | |||||

| steel pipe | Nominal size | 20A-50A(3/4″-2″) | 1-2 | 1-3 | |

| 35A-250A(2 1/2″-10″) | 2-4 | 2-4 | |||

| Stainless steel | Schedule 40 | 20A-50A(3/4″-2″) | 1-2 | 1-3 | |

| 35A-250A(2 1/2″-10″) | 2-4 | 2-4 | |||

| Thin wall stainless steel(SU pipe) | 20-25Su | 0.5 | |||

| 30Su-75Su | 0.5-1 | ||||

| 80Su-125Su | 1-.2 | ||||

| 150Su | 1-3 | ||||

| Plastic pipe(Vinyl chloride/Polyethylene pipe) | 1-2 | 1-2 | |||

| Cast iron pipe | 2-4 | ||||

| Steel | Section steel | Thickness | 1-2mm | 0.5-1 | |

| 2-3mm | 1-3 | ||||

| 3-4mm | 1-2 | 1-3 | |||

| less than or equal 4mm | 2-4 | 2-4 | |||

| Round bar | greater than or equal 15mm | 1-2 | 1-3 | ||

| 16-40mm | 2-4 | ||||

Kouei is Distributor/Agent of REX.

Other items of REX.

Request the quotation for REX.