Atsuchi Tekko Co., Ltd., Japan

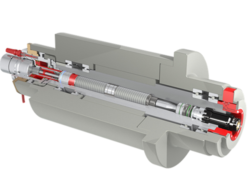

Ascon BAC-5850-1 conveyorwith material handling Autoblasting machine Blast Cabinet

Made in Japan

Manufacturer: Ascon

Model: BAC-5850-1 conveyorwith material handling

Features

This BAC-5850-1 model automates blasting work and improves work efficiency.

This machine delivers workpieces onto a roller conveyor, and continuously blasts and blows air while swinging multiple nozzles on the top and bottom surfaces, respectively. After blasting, the workpiece is transported to the outlet side. At this time, dust, rough waste, etc. are sorted and discharged by the rotary screen, and only clean abrasives are used repeatedly.

Main applications

- Rust, paint peeling, scale removal, peeling

- Nashiji processing, deburring of plastic molded products

- Blasting and surface treatment of high-hardness metals in general

■Suitable abrasive

F16~F220

Specifications

| Model | Model number | width | depth | height | Complacer | Dust collectors | nozzle |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | kw | kW/unit | |||

| conveyorwith material handling | BAC-5850-1 | 4,989 | 1,146 | 2,660 | 37 | 3.7×2 | 7 EK-2× |