Astam Valves, Japan

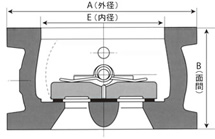

ASTAM C1/C0/C2/C3/C5 Super Check

Product made in Japan

Manufacturer: ASTAM

Model: C1/C0/C2/C3/C5

Overview:

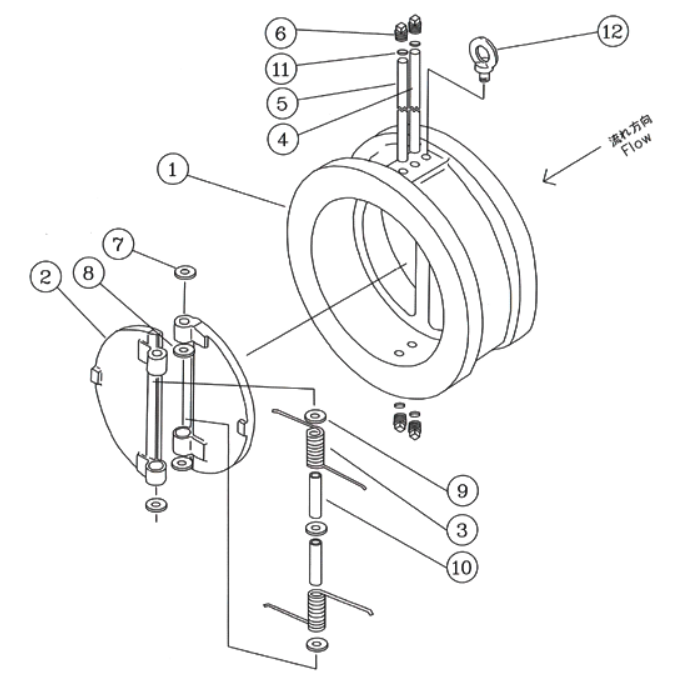

Two semi-circular plates are mounted to the valve body by a hinge pin. When the fluid flows, each plate opens in a V shape centering on the hinge pin and fully opens up to the stop pin.

Characteristics of Super Check Valve

- Short face-to-face dimensions

- It is easy to install and remove the valve to/from the piping in a narrow space.

- Lightweight

- In comparison with the conventional check valves, Astam Check Valves can reduce the burden for the piping.

- Simple structure

- It is easy to maintain because of the small number of assembling parts.

- Various materials

Material for the body, plates, and other parts is an abundant variety for the fluid. - Cylindrical structure

Since the structure is a cylindrical shape, it is suitable for high pressure.

Kinds of Super Check Valve

C1 type (standard type) resilient seat

| There is no leakage at the time of closing by vulcanized rubber bonded on the valve body seat. |

C1 type (standard type) metal seat

| Each seat of the valve body and plates is metal to metal, therefore, it can prevent the reverse flow under the condition of more high temperature・high pressure. |

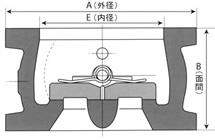

C0 type (O-ring in plate groove)

| FPM O-ing is attached to the plate’s seat, and it can seal perfectly even at extremely low counter pressure (Counter pressure of 2,000mmAq for a horizontal position. *Order Production |

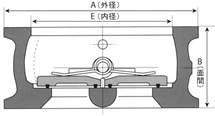

C2 type (Check valve with a by-pass valve)

| A by-pass valve is attached to the valve body. At the time of stopping the pump, by opening a stop valve of the by-pass, it is possible to drain the water of the downflow side. *Order Production |

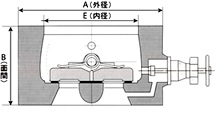

C3 type (Flanged type)

| The valve body and flanges are cast all in one dody. This C3 type is used for the piping of a poisonous gas or flammable gas, or in case it is concerned about the expansion and contraction of the piping bolts with the temperature change. *Order Production |

C5 type (Shock resistant check valve)

| Please use this type if the opening shock of the fluid is huge. The plates of the valve and pins are designed to be tougher than normal products. This structure tolerates severe conditions and can be used long-term by appropriate maintenance. *Order Production |

Specification:

Cautions:

1. Up to 125A, the number of springs is one, and the eye bolt is not attached.

2. From 150A to 550A, the structure is the same as the one illustrated above.

3. 600A and larger, the number of springs is four.

4. Stabilizer is installed only for cast iron valves.

5. The spring sleeve is an option if DN is 350A and larger or the material of the spring is INCONEL X-750.

6. The number of eye bolts is two for your safety if DN is 250A and larger.

| NO. | NAME OF PIECE |

|---|---|

| 1 | BODY |

| 2 | PLATE |

| 3 | SPRING |

| 4 | HINGE PIN |

| 5 | STOP PIN |

| 6 | PLUG |

| 7 | BODY BEARING |

| 8 | PLATE BEARING |

| 9 | SPRING BEARING |

| 10 | SPRING SLEEVE |

| 11 | STABILIZER |

| 12 | EYEBOLT |

Related Products

-

Miyakawa MArX-NEO air handheld-compact

-

Ross Asia Manifold blanking kit For ISO 15407, ISO 5599 & 95 series valves

-

Tohnichi HA/HAC/HACQSPDY Power Torque Wrench

-

SAKUSAKU SAK D155S25-2D Indexable Drill

-

SHOWA SOKKI 1500EX Pressure-resistant explosion-proof vibration switch Vibro switch

-

DIJET SNMG120404-KG, SNMG120408-KG, SNMG120412-KG, SNMG120416-KG Semi-Finishing Insert