Nippon Avionics Co., Ltd.

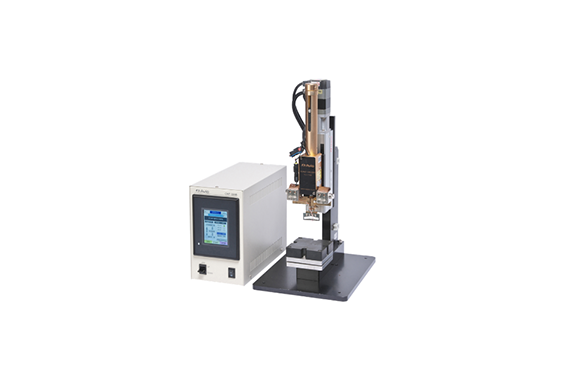

Avio CNT-320B Drive Unit For Pulse Heat (Hot Bar) Soldering Machine

Manufacturer: Nippon Avionics Co., Ltd.

Model: CNT-320B

Linear Slider Drive Head Controller & Linear Slider Drive Unit for Pulse Heat (Hot Bar)

Supports precision joining with 1 micron motor drive resolution.

The electric slider drive head controller and the electric slider drive unit are used in combination.

Features of CNT-320B

- It provides intuitive operation by color touch panel and lever jog switch

- Soft-landing process with a slow moving speed of 0.1mm/sec is provided

- Compatible to high pressure welding processes up to max. 300 N force. (When NA-202PB-B is used)

- Seven operation conditions can be saved

Supplies Specifications of CNT-320B

| Items | CNT-320B & NA-201PB-B | CNT-320B & NA-202PB-B | ||

|---|---|---|---|---|

| Pressure | MAX 150N | MAX 300N | ||

| Drive Method | Linear Slider | |||

| Stroke | MAX 50mm | |||

| Motor Resolution | 1μm | |||

| Power Source (CNT-320B) | DC24V ±5% 4A (Option: AC Adapter AC100 – 240V) | |||

| Dimension / Weight | CNT-320B:W120 x D315.9 x H207mm ≒ 3.7kg | |||

| NA-201PB-B:W57.5 x D82.5 x H311.2mm ≒ 2.0kg | NA-202PB-B:W74 x D103.5 x H368.6mm ≒ 4.5kg | |||

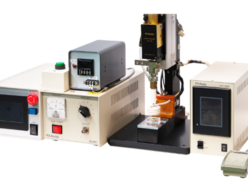

Air Drive Unit for Pulse Heat (Hot Bar)

| Items | NA-221 | NA-222 |

|---|---|---|

| Drive Method | Air | Air |

| Stroke | Max 50mm | Max 50mm |

| Speed Control | with Speed Controller (Φ4mm Tube) | with Speed Controller (Φ6mm Tube) |

| Air Pressure | 0.4 – 0.6MPa | 0.4 – 0.6MPa |

| Dimension | W78 x D83 x H280mm | W86 x D85 x H289mm |

| Weight | ≒ 1.3kg | ≒ 2.2kg |

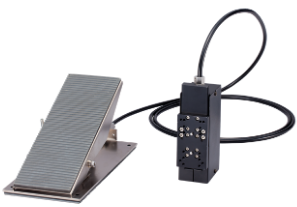

Manual Drive for Pulse Heat (Hot Bar)

| Items | NA-231 | |

|---|---|---|

| Drive Method | Manual by Foot Pedal | |

| Stroke | Max 10mm | |

| Height Control | Range 40mm | |

| Dimension / | Drive Unit:W51 x D79 x H192mm | Foot Pedal:W124 x D268 x H125mm |

| Weight | ≒ 1kg | ≒ 2.2kg |

Related Products

-

Avio R450 Series Infrared Thermal Imaging Camera

-

Avio UI Series High Frequency Induction Heating Machine

-

Avio NRW-DC150A Resistance Welder DC Capacitor

-

Avio Vacuum Semi-Automatic Parallel Seam Sealer

-

Avio NAW-6100/NAW-6000 Parallel Seam Sealer With Automatic Lid Placement

-

Avio MCW-700/MCW-750 Resistance Welder Inverter