Nippon Avionics Co., Ltd.

Avio MCW-700/MCW-750 Resistance Welder Inverter

Manufacturer: Nippon Avionics Co., Ltd.

Model: MCW-700/MCW-750

Features of MCW-700/MCW-750

High Speed Linear Control: allows consistent and precise welding

Multiple Control Modes: constant current, voltage, and power.

High Speed Welding: improves productivity (5 shots / sec)

Pre-Weld Check Function: reduces process sparks

Multiple Graphic Display: simultaneous view of V, I and W waveforms

* Linear control method:The high-speed linear control method achieves stable welding waveform with little switching noise.

Resistance Welding Specifications of MCW-700/MCW-750

| Item | MCW-700 | MCW-750 |

|---|---|---|

| Maximum Current | 500A | 1800A |

| Maximum Voltage | 2V | 4V |

| Constant Current Mode | 10 – 500A | 10 – 1800A |

| Constant Voltage Mode | 0.001 – 2.000V | 0.01 – 4.00V |

| Constant Power Mode | 10 – 500W | 10 – 3600W |

| Welding Time:UP | 0 – 999 × 0.01ms/0.1ms | |

| Welding Time : Weld | 0 – 999 × 0.01ms/0.1ms | |

| Welding Time : Down | 0 – 999 × 0.01ms/0.1ms | |

| Welding Time : Squeeze & Hold | 0.00 – 9.99s | |

| Pre-check | Resistant / Current | |

| Shot / Sec. | 5 shots/sec.(500W 2ms) | 5 shots / sec.(3600W 2ms) |

| Limit Monitoring Function | Average value/Peak value of current, voltage, and power | |

| Waveform Display | Current, voltage and power | |

| Number of Conditions | 15 | |

| Interface | RS-232C、I/O、Analog output | |

| Power Source | 1φ AC100 – 120V ±10% 50/60Hz(Options:1φ AC200 – 240V ±10%) | |

| Dimensions(mm) | W200 × D350 × H300(Excluding protrusions) | W200 × D350 × H400(Excluding protrusions) |

| Weight | ≒20kg | ≒27kg |

Resistance Welding Transformer Specifications

| Model | NT-IN4474 | NT-IN4436 | NT-IN4448 |

|---|---|---|---|

| Power Supply Voltage | 220V | ||

| Cooling Method | Air | Air | Dual Use of Air or Water |

| Frequency | 2kHz | ||

| Rated Capacity | 11kVA | 8.8kVA | 23kVA |

| Transformer Turns Ratio | 37:1 | 18:1 | 24:1 |

| No Load Secondary Voltage | 8.4V | 17.2V | 12.9V |

| Maximum Output Current | 4000A | ||

| Maximum Duty Cycle | 5% | 5% | 5%(Air)、10%(Water) |

| External Dimensions (mm) (Excluding Protrusions) | W150×D337×H222 | W150×D267×H250 | W170×D312×H235 |

| Weight | ≒14kg | ≒14kg | ≒19kg |

Related Products

-

Avio SW-3500-20 Ultrasonic Metal Welding Machine

-

Avio Standard Model Small Size Ultrasonic Metal Welder

-

Avio EH/EP/EO/EL Series Welding Electrode And Resistance Weldability

-

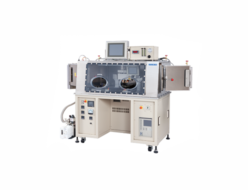

Avio N2 Gas Semi-Automatic Parallel Seam Sealer

-

Avio NA Series Accessories for Weld System Head

-

Avio CNT-320B Drive Unit For Pulse Heat (Hot Bar) Soldering Machine