BEMAC, Japan

BEMAC BE-D11 Offshore Plant Business

Made in Japan

Manufacturer: BEMAC

Model: BE-D11

All-in-One Next-Generation Alarm and Monitoring System The

BE-D11 system is an AII-in-One

system that packs all the necessary functions for engine alarm and monitoring in a compact housing. While retaining its excellent features, we have further refined the three elements.

The BE-D11 system is suitable for any vessel and offers the highest performance

at the best cost, depending on the customer’s requirements, and provides the next generation of standards for engine alarm and monitoring.

Product Features

- apan Railway and Transport Agency (JRTT) Models for Improving Working Environment Vessels

- High Reliability

- Thorough modularization provides high reliability and maintainability. In addition to the CPU, it also supports redundant power supplies and

hot-swapping, greatly reducing system downtime and contributing to safe operation.■ Redundant power supply (optional)

■ CPU hot spare and hot-swap support

■ High durability with minimal wiring and connections

■ Easy-to-maintain structure

- High Performance

- Significantly increase throughput for best-in-class sampling times. In addition, a high-resolution LCD touch

panel is adopted, and the amount of information displayed is 60% higher than that of the BE-D10.■High-speed processing (20ms timestamp)

■High resolution (1,280×1,024pix)

■Maximum measurement point (2,048 points)

- High Flexibility

- Although it is an all-in-one system, we can flexibly respond to your request. In addition,

the mounting dimensions and pinouts of the main unit are the same as those of the BE-D10, and it can be flexibly adapted for retrofitting.■ Supports optimal system configurations from centralized to multiplex communication

■ Up to 16 general-purpose interfaces such as serial and Ethernet can be connected

(connected to other onboard equipment such as onboard LAN systems, ship-to-shore communications, shaft horsepower gauges, and cargo handling systems)

■ Up to 9 expansion cards can be mounted

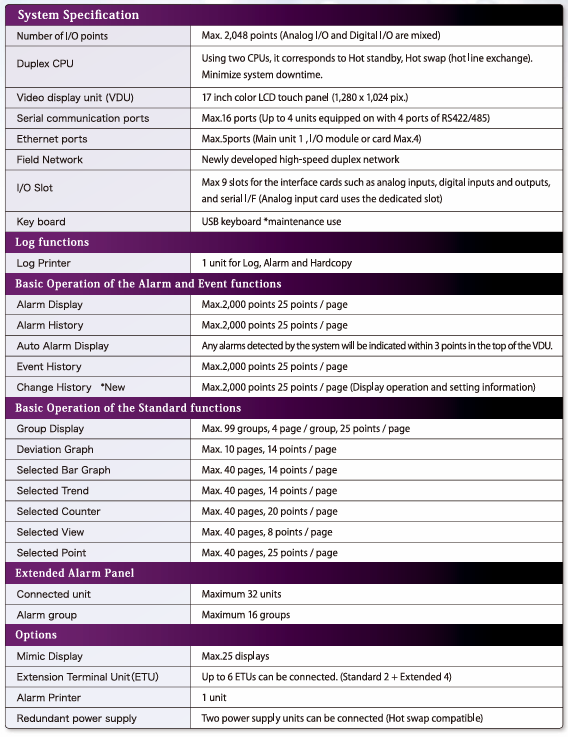

■ Space saving (15% reduction compared to BE-D10) - System Specifications

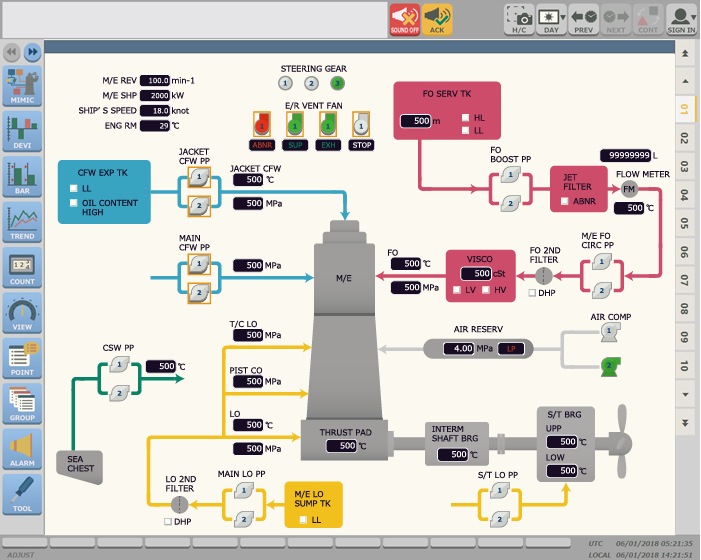

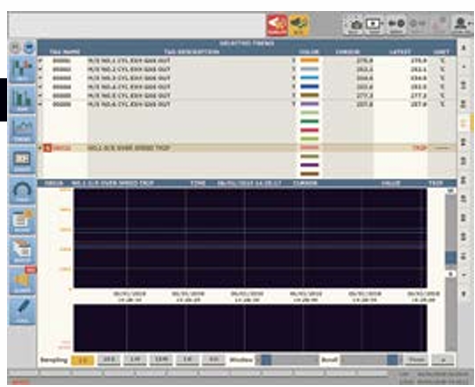

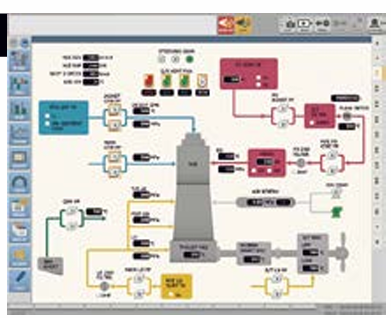

Screen Samples

The three advanced factors of the features

High Reliability

BE-D11 offers high realibity ad maintainability by modularization. The system has rebundant power supply and Hot swap, which enables to reduce downtime significantly and contributes to safe operation.

Rebundant power supply(Option)

Corresponding to Hot spare and Hot swap of CPU

High durability by resucing wiring and connectors to the extreme

High maintainable structureHigh Performance

The high speed processing offers high sampling rate. Realizing 60% up of the displayed information compared to BE-10 by adopting high definition LCE touch panel.

High speed processing(timestamp 20ms)

High resolutio(1280 x 1024pix)

Maximum measuring point(2048 measuring points)High Flexibility

All-in-one system that but we can satisfy your requirements flexibility it can be easy to replace BE-D10 with BE-D11 because the design of the cabinet is completely same.

It is possible to construct the optimized systme such as centralized system and duplex communication.

Up to 16 Points genral interfaces such as serial or Ethernet can be connected.(Connection with shipboard LAN system, Ship-Shore Communication System, Shaft-horsepower meter, loading system and other ship’s equipment etc.)

Up to expansion catds can be installed.

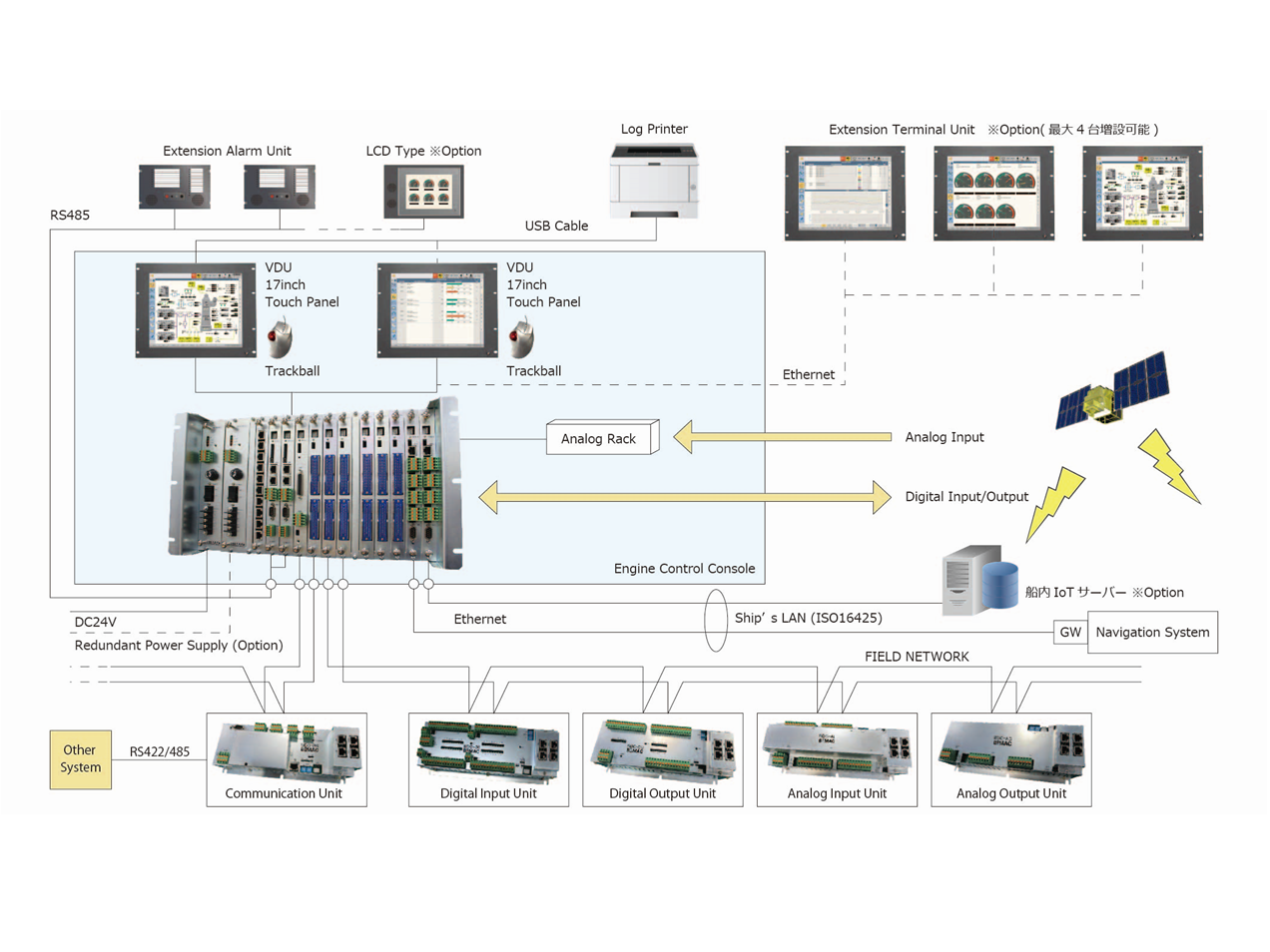

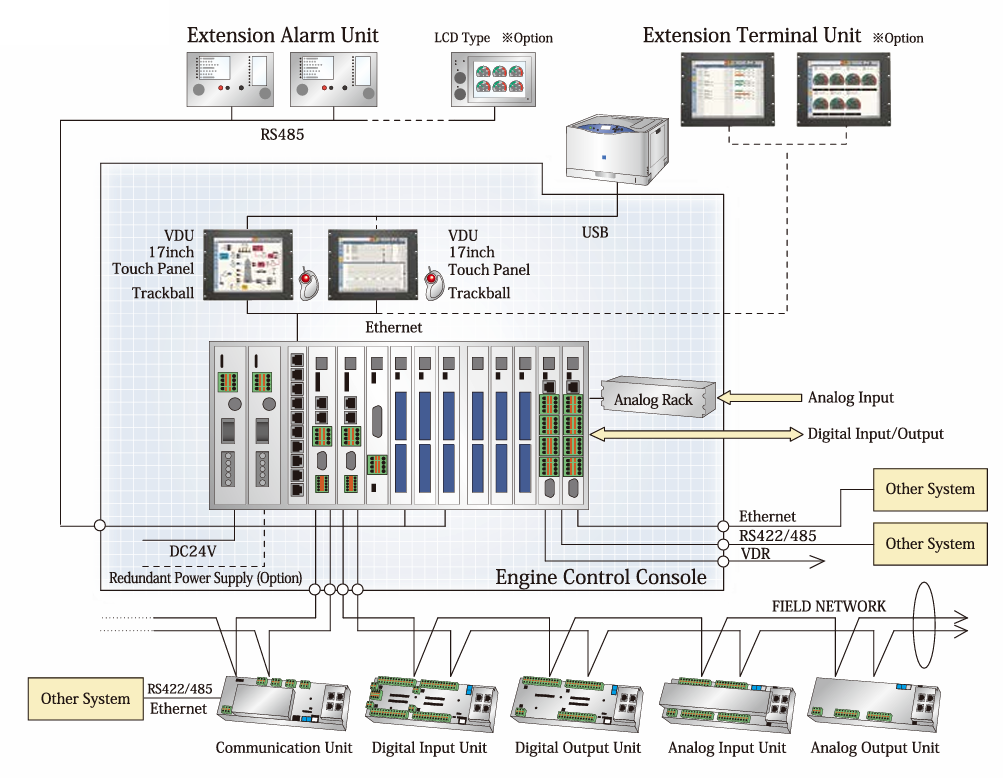

Space-saving ( Reduced by 15% compared to BE-D10)System Scheme

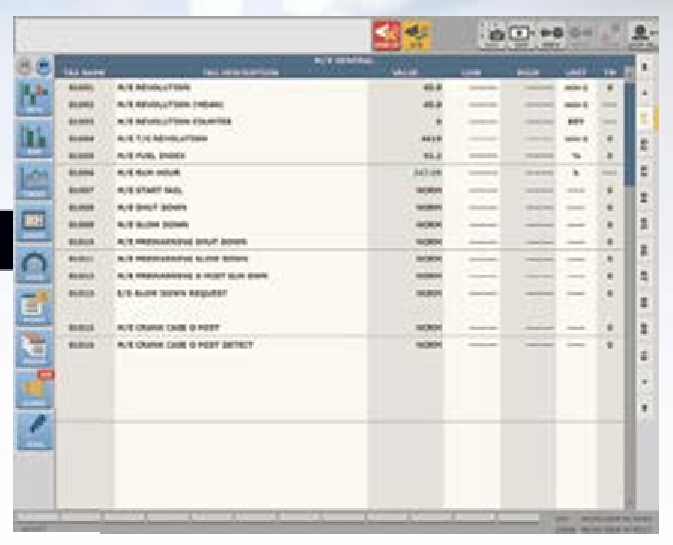

Overview of display

Group Display

All the measuring is divided into maximum 99 groups and the detailed alarm condition and value are displayed.

Selected views

The user can arbitrarily choose me measuring points and display format to monitir. Up to 320 measuring points(max 40 screens) can be displayed by the format of BAR(Horizontal bar graph). BAR(Vertical bar graph), Meter or Lamp.

Selected Trends

Up to 14 analog or digital measuring points are displayed in a screen. The user can arbitrarily choose the measurement points to monitir the trend. All trend data are always stored.

Selected Bargraphs

Up to 14 measuring points are displayed by the format of BAR graph in a screen. The user can arbitrarily choose the measurement points to monitor the Bar Graph.

Deviation Graphs

The exhaust gas temperature, jacket fresh cool water temperature are shown as bar graph, deviation bar graph and trend curve.

Alarm history

The history of Alarm is displayed in chronological order. Up to 2000 points can be stored.

Event History

The meassuring points and the history of state change for system are displayed in chronological order. Up to 2000 points can be stored.

MIMIC DISPLAY(OPTION)

It is possible to remote control of the ship equipments, and display the state of the ship as graphically. Up to 25 displays can be available.

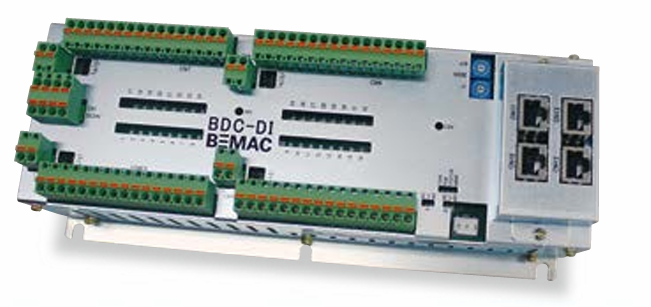

PERIPHERAL EQUIPMENT

Main Data Processing unit

Compact cabinet with function integrated.

Redundant CPU embedded

High capacity of expansion slots(Corresponding to Hot swap)

Superior in compatibilityIntelligent I/O module

High speed field network

Corresponding to Hot swap

Space-saving

Dual power inletOperating Display Unit

High brightness, high resolution module

Resistive film type touch panel

The dimmable function equipped as a standardSpecification

Kouei is Distributor/Agent of BEMAC.

Other items of BEMAC

Request the quotation for BEMAC.

Related Products

-

Kondotec VXKW1 Series Shortening Pin Type Pewag Chain Sling

-

DIJET RNM-R Series Insert For Mirror Radius

-

BIX BD-4 Small Electric Driver Bits

-

DIJET ZPMT100304ZER-PL, ZPMT100308ZER-PL, ZPMT100320ZER-PL High Precision Insert For Shoulder Scraping (For Semi-finishing To Finishing)

-

Eight Tool CN-M Multi Tool

-

TONE UJ20 Universal Joint