Japan

Blastriker

Made in: Japan

Model: Blastriker

Unprecedented innovation in surface preparation!

The new solution for a hassle-free and efficient surface preparation hand tool

Traditional surface preparation methods, while capable of ensuring a reliable process, have various problems including the difficulty of handling, costs, environmental burdens (such as dust dispersion, noise, waste), and worker safety. Evolmech (エボルメック) introduces the Blastriker (ブラストライカー), a new hand tool that addresses these issues while maintaining the quality of surface preparation equivalent to conventional blasting methods. It is easy to operate, allowing for speedy and safe progress on construction sites. It is also cost-effective and suitable for a wide variety of situations. This tool can significantly enhance work efficiency and provide a new option for the construction industry.

High Durability

Evolmech has achieved a durability that withstands the test of time. The selection of high-quality materials and the application of our unique technology ensure that the tool is resistant to wear and tear, significantly extending its lifespan and reducing the frequency of tool replacement.

Ease of Use – Efficiency

The unique shape of the hand tool fits comfortably in the hand, and the balanced design reduces fatigue during work. As a result, the Blastriker allows for a more efficient and comfortable work process.

Work Efficiency

The design of the Blastriker aims to boost work efficiency by offering innovative features and streamlined processes. It reduces the workload on the user, enabling prolonged use without excessive fatigue. This helps to improve overall work efficiency and may also contribute to reducing the risk of work-related accidents.

Environmental Consideration

Developers created the Blastriker to minimize environmental impact, focusing on eco-friendly innovations and sustainable practices.It reduces the generation of waste and dust, contributing to a cleaner work environment. It also minimizes the noise often associated with blasting operations, making it a more environmentally friendly option for surface preparation tasks.

Easy Blade Replacement! Enhanced Durability and Performance

The Blastriker’s core feature is the ease with which the blade can be replaced.

The Blastriker’s core feature is the ease with which the blade can be replaced.

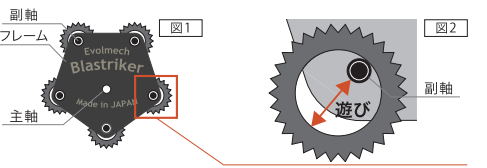

(①) The uniquely designed blade attachment allows for the blade to be changed quickly and easily (Blast Method), reducing downtime.

(②) Additionally, by simply flipping the blade, a fresh edge can be used, which doubles the usage life of the blade and contributes to both improved performance and cost savings

| Item | Specification | Value | Blastriker |

| Surface Preparation Quality and Efficiency |

Impact Work (with a note indicated by *1 |

N・m | 0.045 |

| Impact Location | Permitted | 5 | |

| Number of Impacts (with a note indicated by *2) |

回/ second | 19,000 | |

| Material Hardness (with a note indicated by *3) |

HRC | 60 | |

| SDGs | Power Consumption | W | 200 |

*1 For maximum torque, the torque meter (separate sale) is used to measure the torque applied to the blade.

*2 For maximum rotational speed, it refers to the maximum number of rotations possible.

*3 For material hardness, it indicates the Rockwell hardness (scale C) of the product

Rapid cleaning with 8 hours of continuous operation

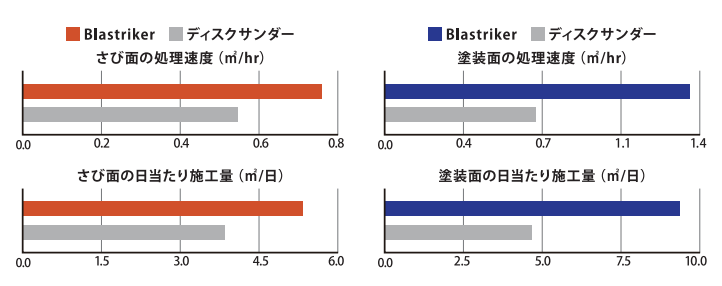

The Blastriker, capable of continuous use for over 8 hours, sets a new standard in average performance and durability. Rz JIS 40μm. It has a stable ability to form roughness and allows work to proceed smoothly without the need for frequent exchanges. For painting boards, it achieves a processing speed of 1.34m2/hr, which is approximately twice as fast as a disc sander, contributing to a reduction in man-hours.*4

*4 Based on internal verification results (Note) The processing speed and the amount of construction can be greatly affected by factors such as the thickness of rust and paint layers.

Outstanding cost performance contributes to shorter construction periods!

| Blastriker | General blasting method | |

| Required Equipment | Our specialized tools, Blastriker, generator | 4t truck, air compressor, generator. Plast machine, complete hose set, grinding materials, dust collector, dust collection hose. |

| Staff | 1 person The tool is easy to use and requires minimal preparation. It produces less dust dispersal, allowing for safe operations. |

■ 3 people One work staff and two support staff. Protective measures against dust dispersal are necessary, so preparation for the work takes time. |

| Construction Site | Suitable for narrow spaces and urban areas Its handy size is suitable for tight spaces. It can also be used in urban areas where it’s difficult to install protective coverings due to the dense building layout. |

▲ Depending on the surrounding environment, usage can be limited. If it’s not possible to bring in and set up the blasting equipment, the work cannot be performed. |